Quick connecting ball pair type coupler

A technology of couplings and balls, applied in couplings, elastic couplings, mechanical equipment, etc., can solve the problems of rubber elastic fatigue damage, low efficiency, and reduced torsional vibration strength of elastomers, so as to improve the bearing capacity. and stiffness, fast coupling and disassembly, reducing the effect of unbalanced moments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

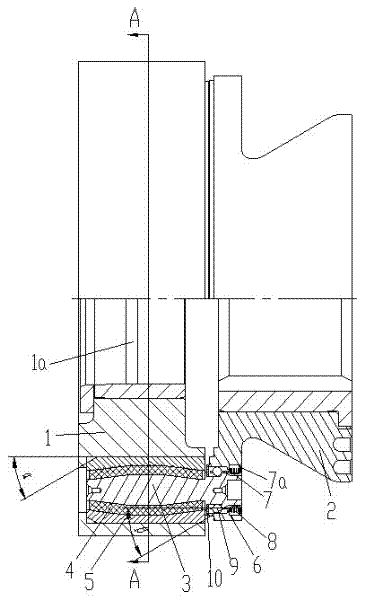

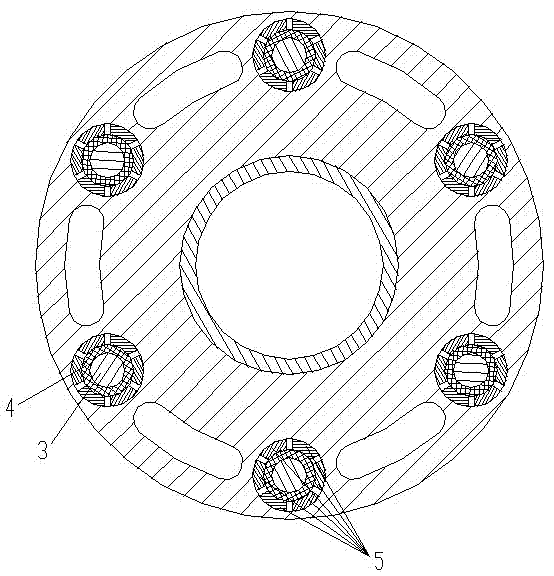

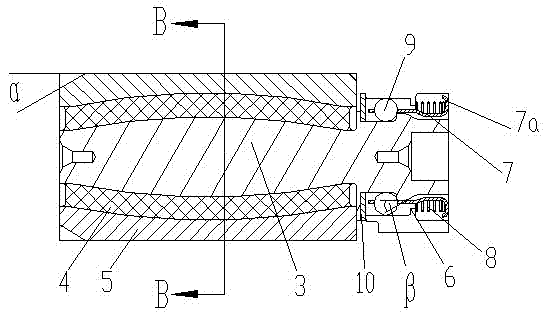

[0022] attached figure 1 A half-sectional view of the overall structure of the quick coupling ball coupling, attached figure 2 for figure 1 Sectional view along A-A direction, attached image 3 It is a schematic diagram of the assembly structure between the coupling body, the cage and the steel ball, and the attached Figure 4 for image 3 Sectional view along BB direction.

[0023] As shown in the figure, the quick coupling ball pair coupling of the present invention includes an input shaft flange 1 for fixed connection with the input shaft and an output shaft flange 2 for fixed connection with the output shaft, the input shaft Blind holes are evenly distributed along the axial direction of the coupling on the circumference of the flange 1, and through holes corresponding to the blind holes are uniformly distributed along the axial direction of the output shaft flange 2 along the axial direction of the coupling, including A connecting body that connects the input shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com