Rotor-type internal-compression oil-gas mixed transport pump unit

An oil-gas mixed transport pump and internal compression technology, which is applied in the direction of rotary piston pumps, rotary piston machines, pumps, etc., can solve the problems of high difficulty, inability to fully recover natural gas, and limitations, and achieve the effect of complete recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

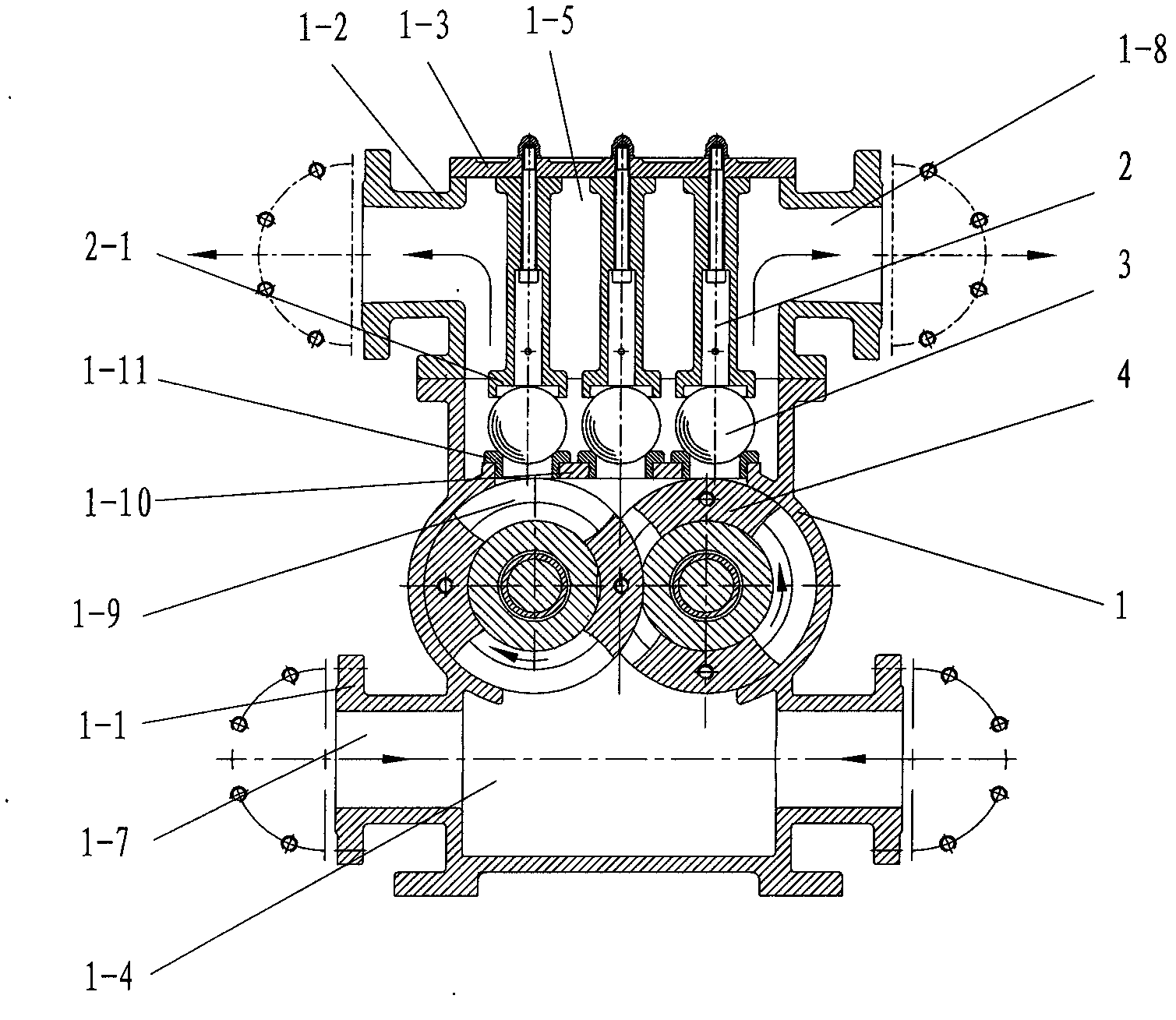

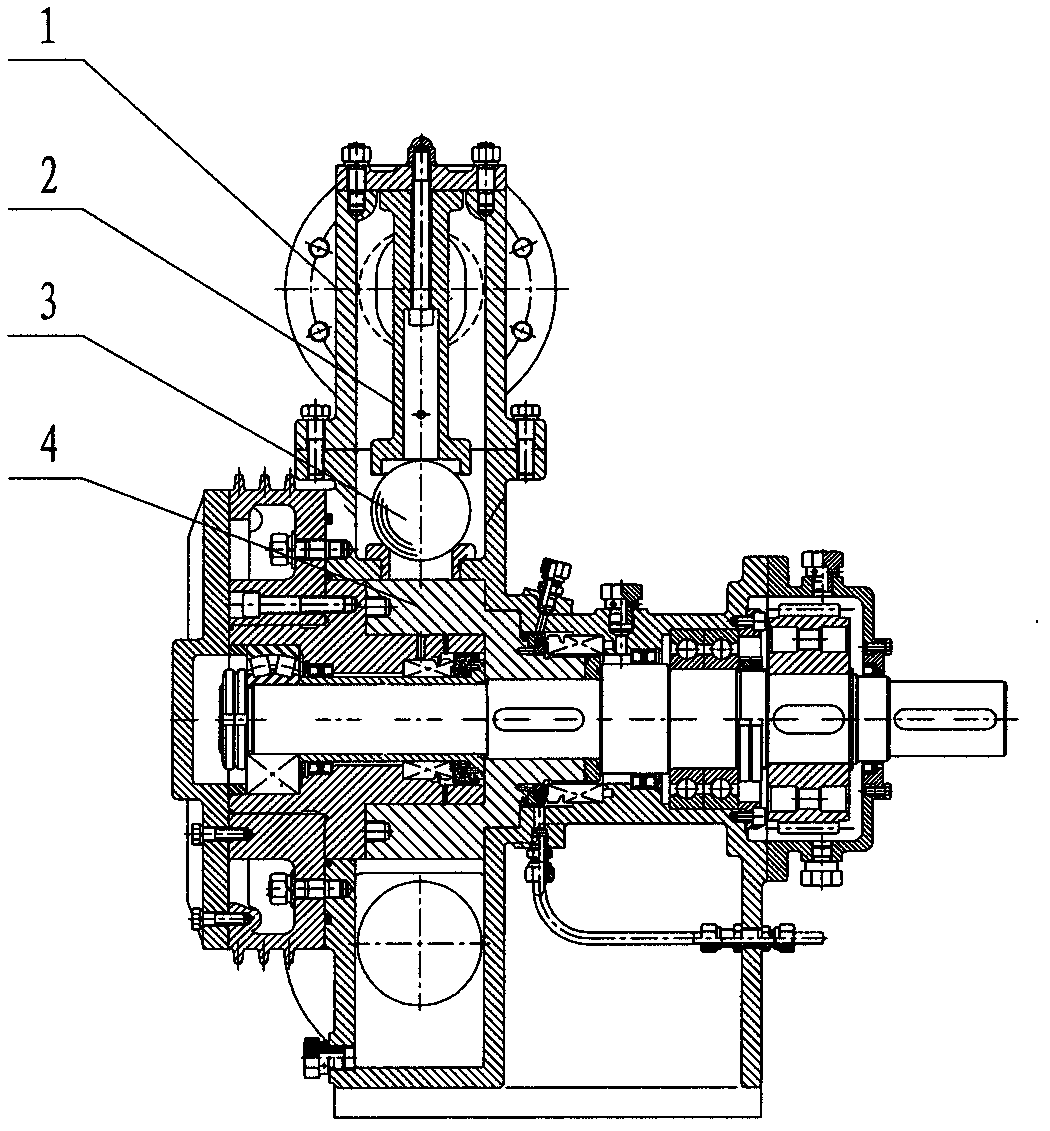

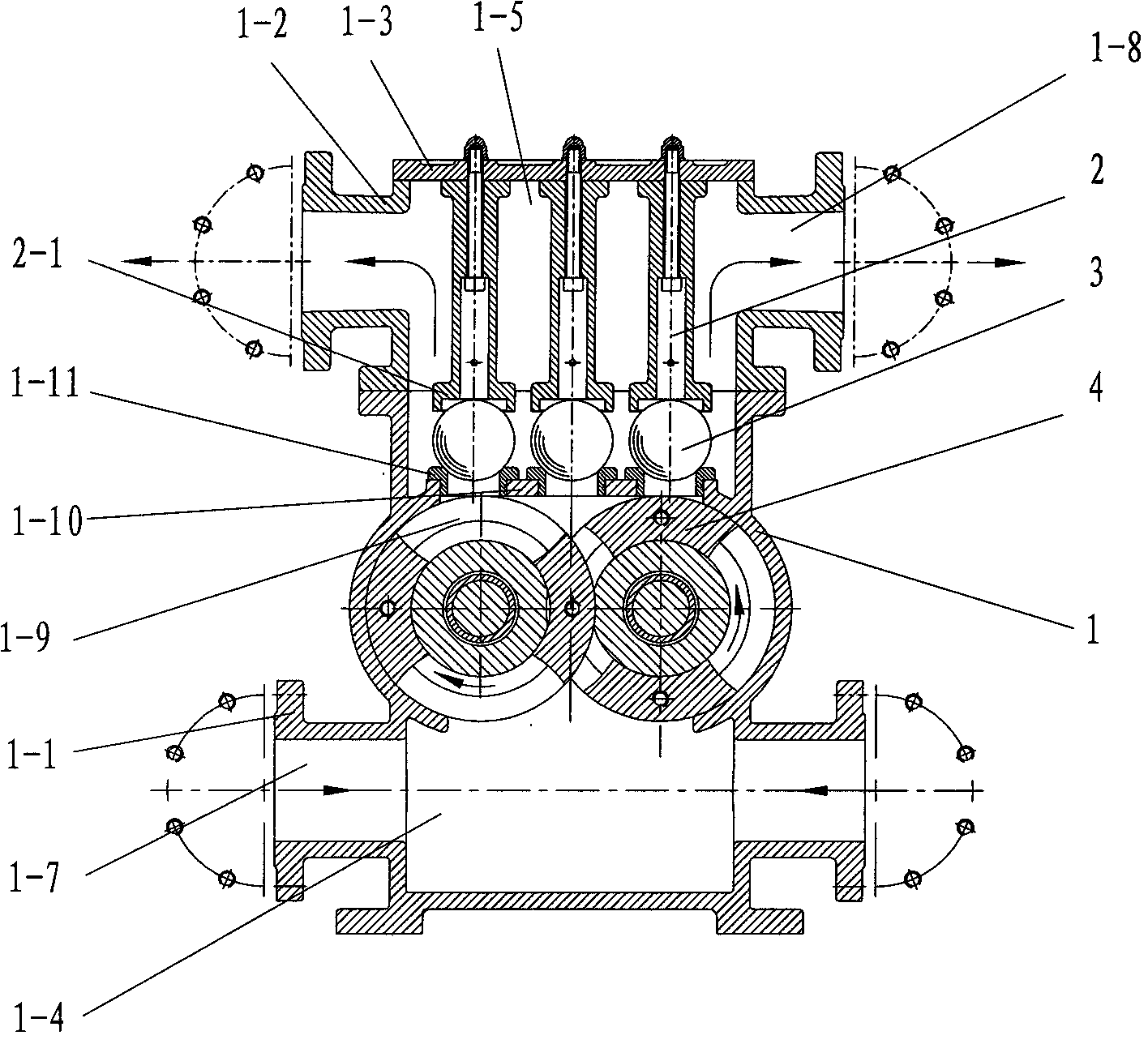

[0015] The rotor-type internal compression oil-gas mixed delivery pump unit of this embodiment is as follows: figure 1 , figure 2 As shown, the housing 1 is composed of a lower housing 1-1, an upper housing 1-2 and an upper housing cover 1-3, and the assembly is very convenient. The middle of which supports a pair of mutually meshing conjugate rotors 4 through bearings. The rotating shafts of the conjugate rotor 4 are in the same horizontal plane, and the cavity in the housing 1 is divided into a suction cavity 1-4 and a discharge cavity 1-5. Both sides of the suction chamber 1-4 are provided with fluid inlets 1-7, and both sides of the discharge chamber 1-5 are provided with fluid outlets 1-8. A partition wall 1-10 is provided between the conjugate rotor 4 and the fluid outlet 1-8 to separate the discharge chamber 1-5 into an engagement area 1-9 and a discharge area. The lower surface of the partition wall 1-10 is at a position tangent to the outer circle of the conjugate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com