Insulation cylinder used in laser crystal growth process

A growth process, laser crystal technology, applied in the direction of crystal growth, post-processing equipment, after treatment, etc., can solve the problems of large thickness and difficulty in ensuring consistent density of the insulation layer, achieve small thermal deformation, reduce the risk of crystal growth, Increased effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

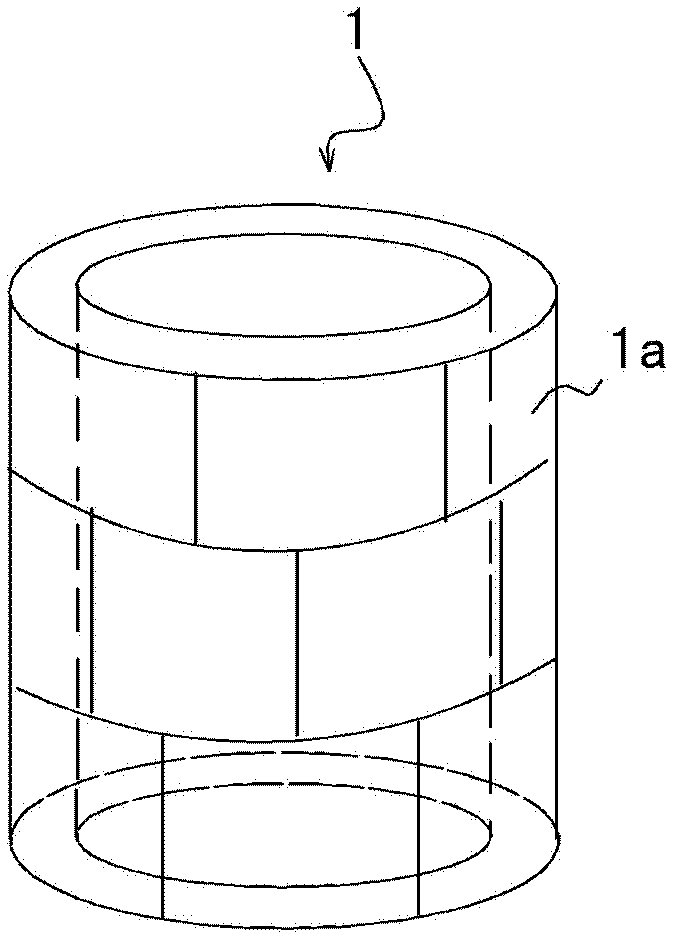

[0015] see figure 1 , figure 2 In this embodiment, the insulation tube 1 is set as a split structure, and the split structure is that the entire insulation tube 1 is divided into each unit component 1a, and each unit component 1a is spliced with each other to form a cylindrical body.

[0016] In specific implementation, the distribution of each unit member 1a in the insulation cylinder 1 is:

[0017] The thermal insulation cylinder 1 is arranged to be a superimposed structure of a plurality of circular rings in the axial direction, and each circular ring is equally divided into tile shapes on the circumference; adjacent tiles are embedded with stepped surfaces.

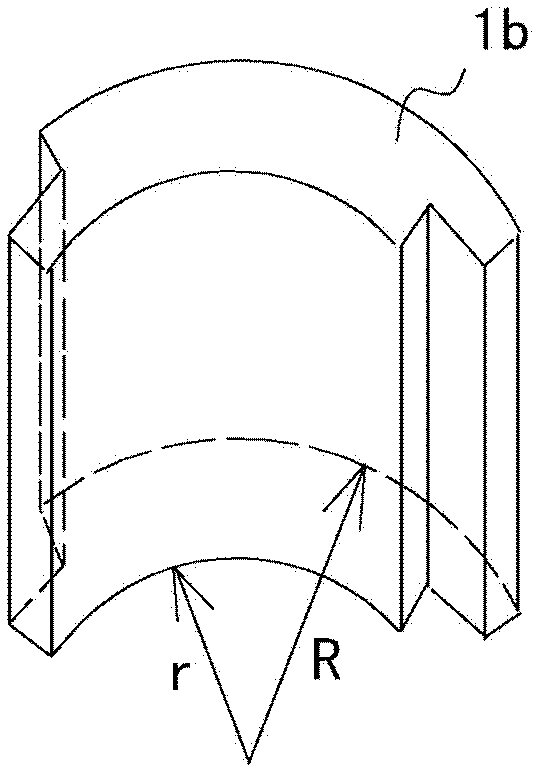

[0018] figure 2 The circular ring shown is equally divided into six tiles 1b on the circumference, the central angle of each tile 1b is 60 degrees, the height is 50-55mm, the radius r of the inner circle is 170-180mm, and the radius R of the outer circle is 185mm -197mm, the adjacent tiles 1b on the ring are em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com