Resin composition for laser beam welding, article for laser beam welding, and composite molded article

A resin composition and laser welding technology, applied in laser welding equipment, welding equipment, applications, etc., can solve the problem of laser transmittance reduction and achieve the effect of preventing appearance deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

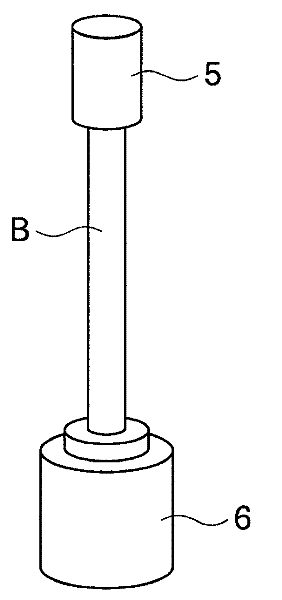

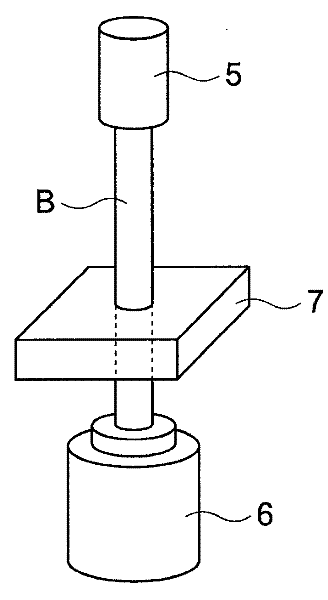

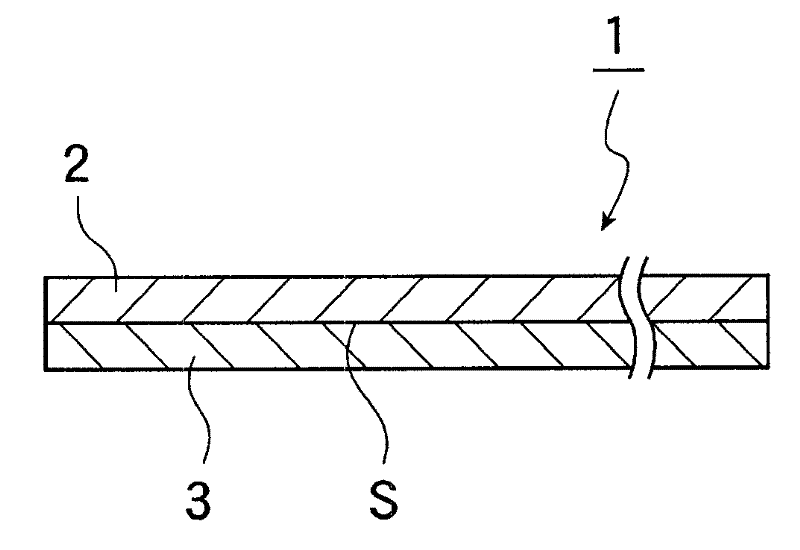

[0024] FIG. 1 shows Embodiment 1 of the present invention.

[0025] As shown in FIG. 1 , the composite molded body 1 according to Embodiment 1 is formed by joining a transmission-side to-be-welded object 2 and an absorption-side to-be-welded object 3 at the interface S of both by laser welding to be integrated.

[0026] When manufacturing the composite molded body 1, the transmission-side object to be welded 2 and the absorption-side object to be welded 3 are brought into contact, and the interface S of both is irradiated with laser light through the transmission-side object to be welded 2, and the transmission-side object to be welded 2 and the absorption-side object to be welded are irradiated with laser light. The absorbing side is welded by laser welding 3 .

[0027] The object to be welded on the transmission side 2 is formed of a molded body for laser welding, and the thickness of the molded body for laser welding is 0.5 to 6 mm (preferably 1 to 3 mm). If the thickness ...

Embodiment 1

[0059] 80 parts by mass of aromatic polysulfone resin "Sumika Exel PES 3600P" (glass transition temperature Tg = 225°C) manufactured by Sumitomo Chemical Co., Ltd. and glass fiber "CS03JAPx-1" (single fiber) manufactured by Owens Corning Japan Ltd. Diameter 10 μm, refractive index 1.56) 20 mass parts are mixed, with respect to this mixture 100 mass parts, after adding 0.2 mass parts of triphenyl phosphate manufactured by Wako Pure Chemical Industries Co., Ltd. as a heat stabilizer, use (KK) Ikegai product A twin-screw extruder "PCM-30" was melt-kneaded to prepare pellets containing a resin composition for laser welding. As melt-kneading conditions at this time, the barrel set temperature of the twin-screw extruder was set to 330° C., and the screw rotation speed was set to 150 rpm. The barrel set temperature referred to here refers to the average value of the set temperatures of the heating devices installed from the most downstream portion of the barrel to about 2 / 3 of the ba...

Embodiment 2

[0061] Pellets containing the resin composition for laser welding were prepared in the same manner as in Example 1 above except that glass fiber "CS03MAFT692" (single fiber diameter: 13 μm, refractive index: 1.56) manufactured by Owens Corning Japan Ltd. was used instead. Table 1 is the composition table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com