Resin composition as well as semi-solidified rubber sheet, laminating board and circuit board containing same

A resin composition and resin technology, applied in circuit substrate materials, synthetic resin layered products, printed circuit parts, etc., can solve problems such as unsatisfactory flame retardancy and poor reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

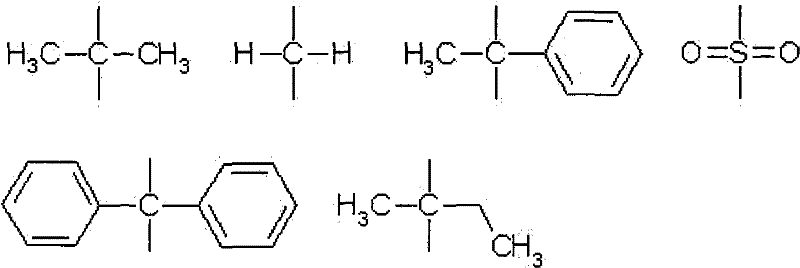

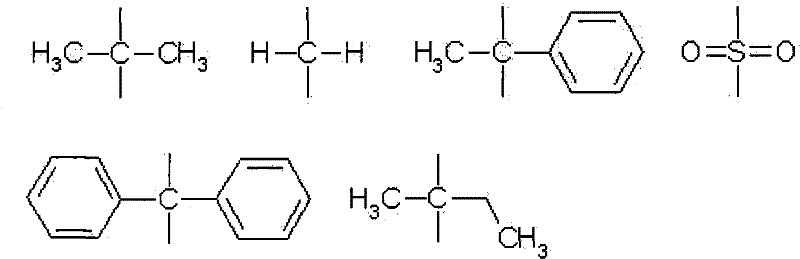

Method used

Image

Examples

Embodiment 1

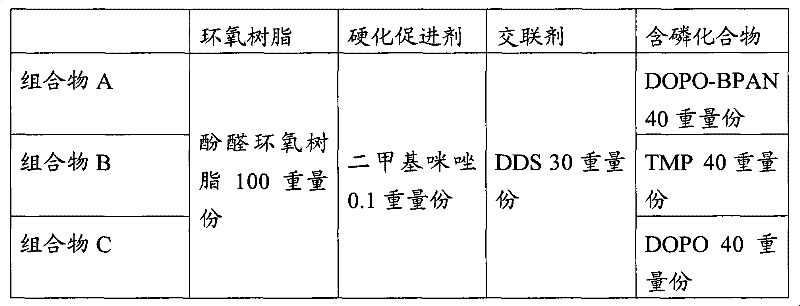

[0049] A resin composition comprising the following components:

[0050] (A) Novolac epoxy resin of 100 parts by weight

[0051] (B) 30 parts by weight of DDS

[0052] (C) DOPO-BPAN resin of 40 parts by weight

[0053] (D) Dimethylimidazole of 0.1 parts by weight

Embodiment 2

[0055] A resin composition comprising the following components:

[0056] (A) 100 parts by weight of bisphenol A epoxy resin

[0057] (B) 40 parts by weight of phenol novolac (phenolic novolac) resin

[0058] (C) 20 parts by weight of DDS

[0059] (D) DOPO-BPAN resin of 20 parts by weight

[0060] (E) dimethylimidazole of 0.1 weight part

Embodiment 3

[0062] A resin composition comprising the following components:

[0063] (A) 100 parts by weight of dicyclopentadiene epoxy resin

[0064] (B) 30 parts by weight of DDS

[0065] (C) DOPO-BPAN resin of 45 parts by weight

[0066] (D) fused silica of 50 parts by weight

[0067] (E) 1 part by weight of siloxane compound

[0068] (F) 50 parts by weight of methyl ethyl copper

[0069] (G) dimethylimidazole of 0.1 parts by weight

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com