Technology for preparing silane by reacting lithium aluminum hydride with silicon tetrachloride in aether medium

A technology of silicon tetrachloride and lithium aluminum hydride, applied in the direction of silicon hydride and the like, can solve problems such as pollution, and achieve the effects of reasonable process technology and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

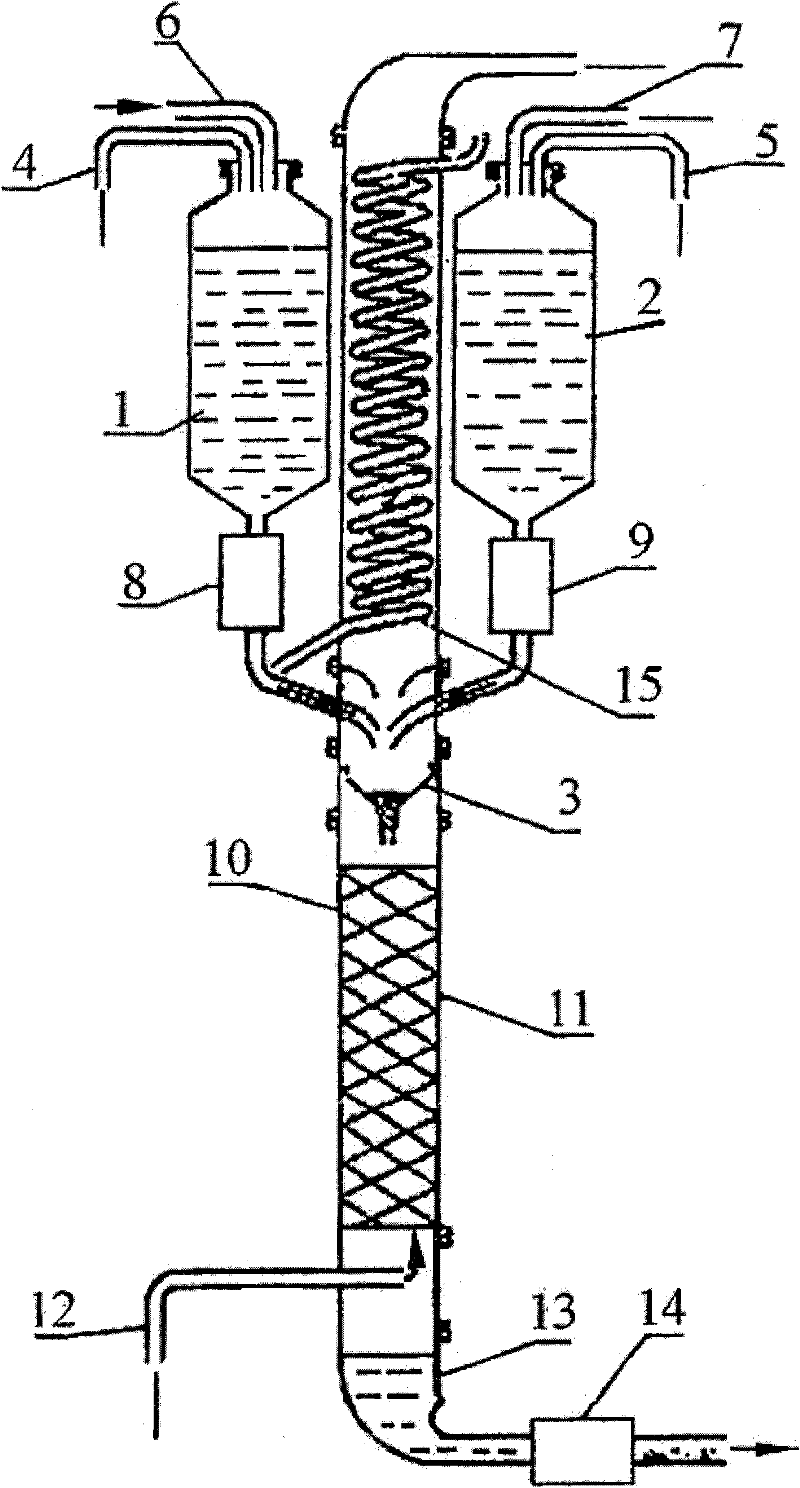

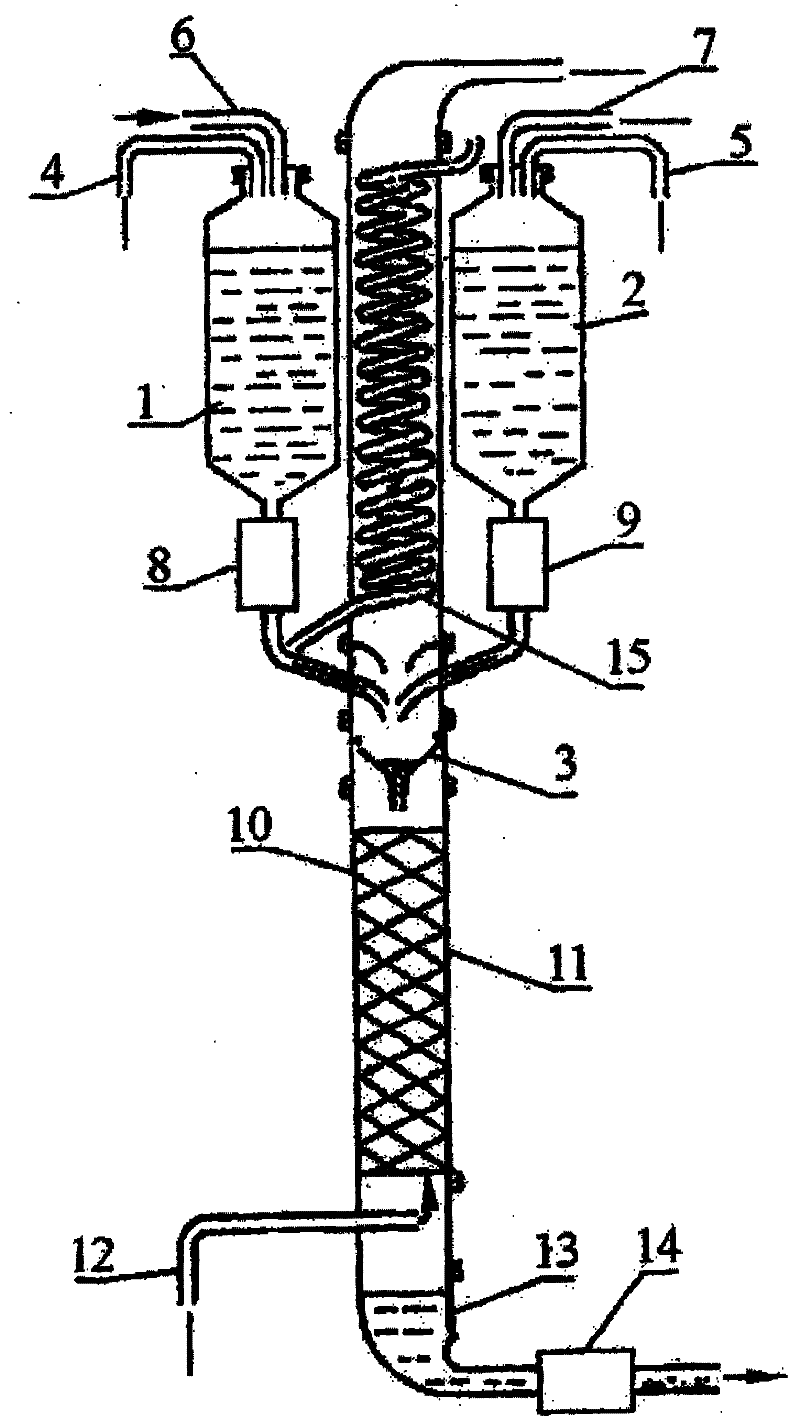

[0016] refer to figure 1 , making an integrated condenser (15) connected to the pre-mixer (3), the left side of the pre-mixer (3) connected to the left metering controller (8), the right side of the pre-mixer (3) connected to the right metering controller (9), the left The metering controller (8) is connected to the large-capacity left storage tank (1), the right metering controller (9) is connected to the large-capacity right storage tank (2), and the left liquid supply pipe (4) is connected and installed on the large-capacity left storage tank (1). ) and the left inert gas outlet (6), the large-capacity right storage tank (2) is connected and installed with the right liquid supply pipe (5) and the right inert gas outlet (7), and the pre-mixer (3) is connected and installed with an internal filler (11) The reaction chamber (10), H 2 The inlet (12), the waste liquid storage tank (13), and the metering control system (14) are assembled into one body to form.

[0017] The pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com