Aerated automobile body longitudinal beam

A car body and inflatable technology, which is applied to vehicle components, vehicle safety arrangements, pedestrian/passenger safety arrangements, etc., can solve problems such as inability to adapt to various forms of collision energy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

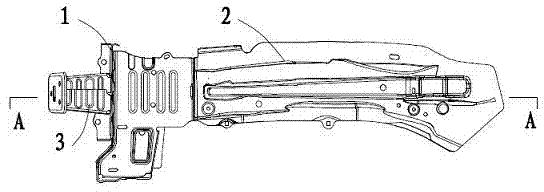

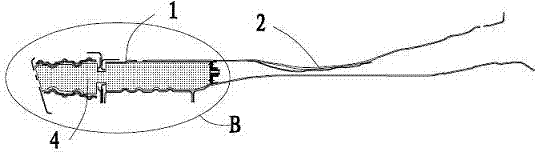

[0020] Embodiment: a kind of inflatable automobile body stringer, as figure 1 , figure 2 , image 3 shown. The vehicle body longitudinal beam comprises a longitudinal beam front part 1 connected with the front bumper and a longitudinal beam rear part 2 connected with the front fender of the vehicle. The longitudinal beam of the vehicle body is a hollow structure, the wall thickness of the front part 1 of the longitudinal beam is small, and a guide groove 3 is provided on the side wall to guide the collapse direction of the front longitudinal beam during a collision, and the wall thickness of the rear part 2 of the longitudinal beam is thick, and is strengthened Structures such as boards increase rigidity and protect occupants.

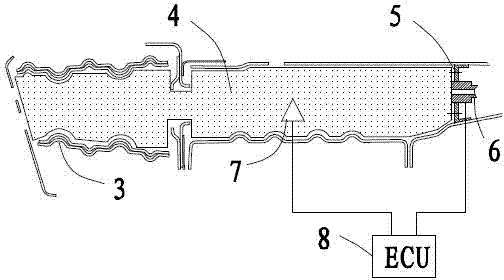

[0021] Such as figure 2 , image 3 As shown, the interior of the front part 1 of the stringer is provided with an air bag 4, which is pre-filled with gas of 3 times the atmospheric pressure. Attached to the front end of the front part 1 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com