Automatic temperature control cooling device for plastic granulation

A cooling device and granulation technology, applied in the direction of coating, etc., can solve the problems of a large number of granules easily produced by granulation, difficult cooling of plastic strips, low heat exchange efficiency, etc., to meet the needs of injection molding, save energy, protect environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

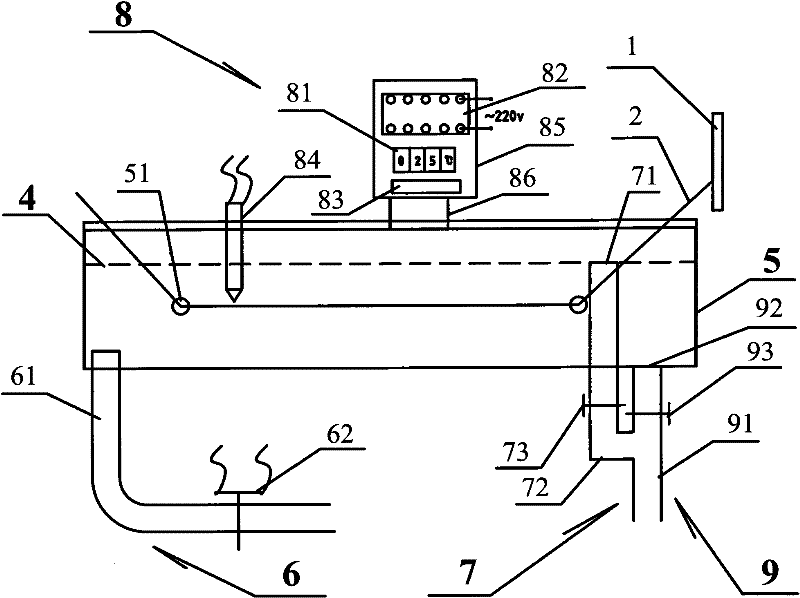

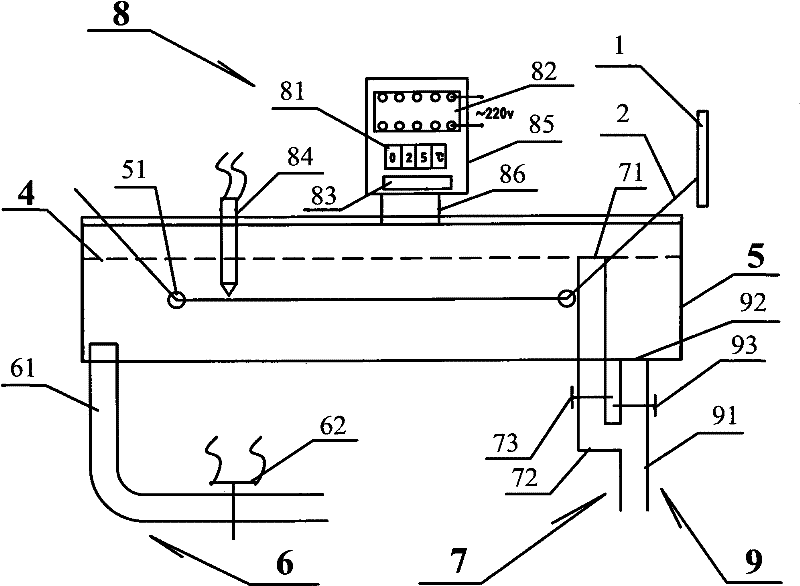

[0024] Combine the following figure 1 , to describe preferred embodiments of the present invention in detail.

[0025] Such as figure 1 as shown, figure 1 It is a schematic diagram of the overall structure of the present invention. An automatic temperature-controlled cooling device for plastic granulation, comprising a water tank 5 engraved with a safety water level line 4 , a water inlet component 6 , a safe water level outlet component 7 , a temperature control component 8 and a drainage component 9 .

[0026] The inside of the water tank 5 is provided with a pressure roller 51 fixedly connected to the water tank 5 by welding, and the safety water level 4 is 5 to 20 cm higher than the position of the pressure roller 51 in the water tank 5, so as to ensure that the material strip 2 is immersed in the water tank during normal production. 5 in the cooling water. The pressure roller 51 arranged in the water tank 5 immerses the molten plastic strip 2 extruded by the extruder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com