Method for parallel winding of outer rotor via stator iron core and winding device thereof

A technology of stator iron core and winding method is applied in the field of parallel winding of stator iron core for outer rotor, which can solve the problems of overall thickening and difficulty in high-density winding, and achieve the effect of simplifying the driving structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

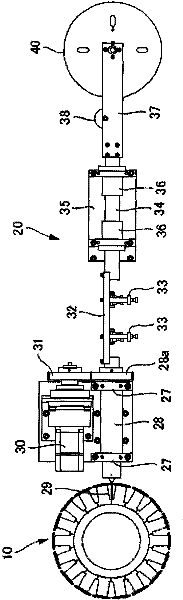

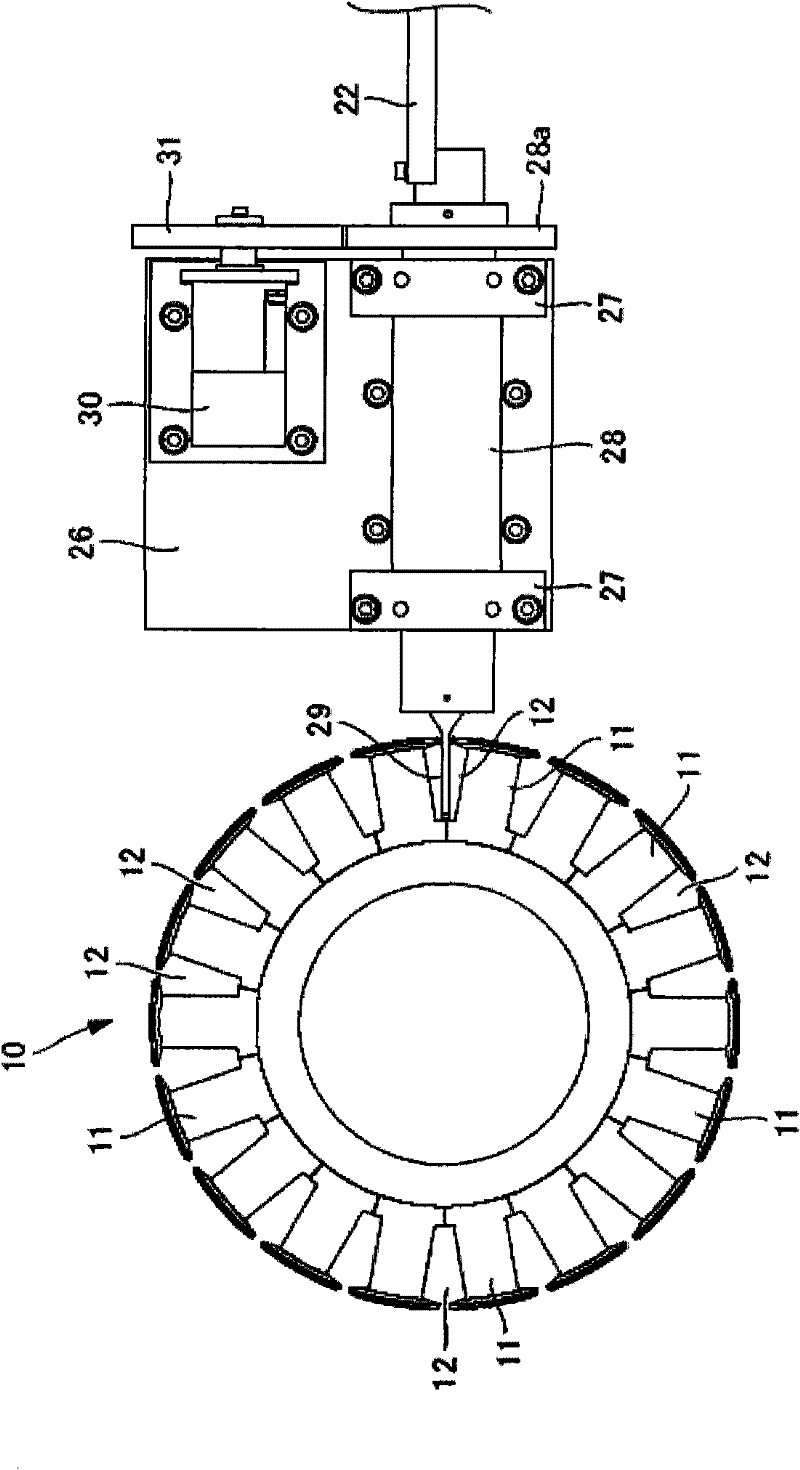

[0145] Hereinafter, embodiments of the winding device in the present invention will be described with reference to the drawings.

[0146] Figure 1 to Figure 13 An embodiment of the winding device of the present invention is shown. Such as image 3 As shown, the winding device performs winding on the stator core 10 for the outer rotor.

[0147] The outer periphery of the stator core 10 has a plurality of protruding teeth 11 , and slots 12 are formed between the protruding teeth 11 .

[0148] Figure 1 to Figure 7 The structure of the nozzle drive part 20 of this winding apparatus is shown.

[0149] Such as figure 1 and figure 2 As shown, the nozzle driving part 20 has a support platform 21 on which a guide rail 22 is arranged. Also, a slider 23 is slidably installed along the guide rail 22 . A first motor 24 is installed at the rear end of the guide rail 22 , and the rotating shaft of the first motor 24 is connected with a ball screw 25 .

[0150] The ball screw 25 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com