Preprocessing system for near-infrared online detection and application thereof

A pretreatment, near-infrared technology, used in the preparation of test samples, measurement devices, color/spectral characteristics measurement, etc., can solve the problems of spectral acquisition repeatability, poor stability and reliability, and achieve online quality control, The effect of spectral stability and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

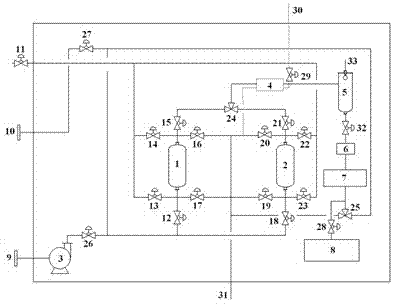

[0027] see figure 1 , the present invention provides a near-infrared on-line detection pretreatment system, which consists of a filter 1, a spare filter 2, a frequency conversion centrifugal pump 3, a temperature control device 4, a buffer device 5, a flow meter 6, a near-infrared spectrum acquisition device 7, an automatic Sampling device 8, liquid inlet 9, and liquid outlet 10. Filter 1 discharges liquid through the filter pneumatic switch valve 15. Backup filter 2 discharges liquid through the backup filter. The through valve 24 is connected to the main pipeline of the temperature control device 4, and the frequency conversion centrifugal pump 3 is connected to the pneumatic switch valve 26 of the liquid inlet. After that, the liquid is divided into two paths, one of which is connected to the pneumatic switch valve 27 of the liquid outlet, and the pneumatic switch valve 27 of the liquid outlet is connected. The switch valve 27 is connected with the liquid outlet 10, and the...

Embodiment 2

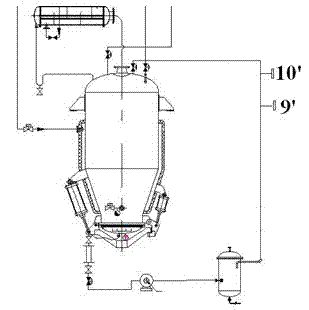

[0034]see Figure 1~2 , Extraction process of Radix Paeoniae Rubra: Add 250 kg of Radix Paeoniae Rubra, add 10 times the amount of purified water to soak for 1 hour, extract at 100 °C for 2 hours, and install an external circulation between the bottom and the top of the 3-ton extraction tank (production equipment) The pipeline ensures the continuous circulation of the extraction liquid during the extraction process, so that the medicinal liquid in the extraction tank is evenly distributed and prevents the local concentration from being too high. Connect the liquid inlet 9 and the liquid outlet 10 to the ports 9' and 10' of the external circulation pipeline of the 3-ton extraction tank respectively (see figure 2 ), the cleaning fluid pneumatic switch valve 11 is connected to purified water.

[0035] Start the automatic control system. After the soaking process is over, turn on the frequency conversion centrifugal pump 3, the pneumatic switch valve 26 at the liquid inlet and t...

Embodiment 3

[0049] The mixed extraction process of Chuanxiong, Danshen and Angelica: each 60 kg of Chuanxiong, Danshen and Angelica, add 10 times the amount of purified water to soak for 1 hour, and then extract at 95°C for 2 hours.

[0050] According to the method of embodiment 2, do not use this pretreatment system, directly collect near-infrared spectrum by conventional on-line detection device, analyze the ferulic acid concentration and solid content in the extract sample that collects, establish ferulic acid and solid content The partial least squares model was used to analyze the concentration and solid content of ferulic acid in the extraction process. Similarly, using this pretreatment system, according to the above modeling process, the near-infrared partial least squares model of ferulic acid and solid content was established respectively, and it was applied to the online analysis of ferulic acid in the mixed extraction process of Chuanxiong, Danshen and Angelica. Acid concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com