Truss string structure

A beam structure and component technology, applied in the field of suspension beam structure, can solve the problem of uneven stress of suspension beam structure, and achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

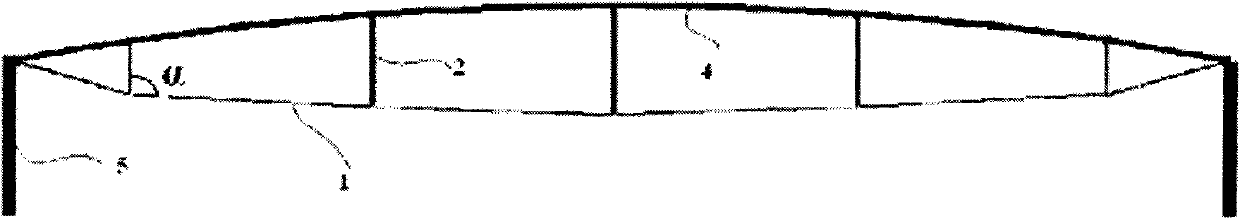

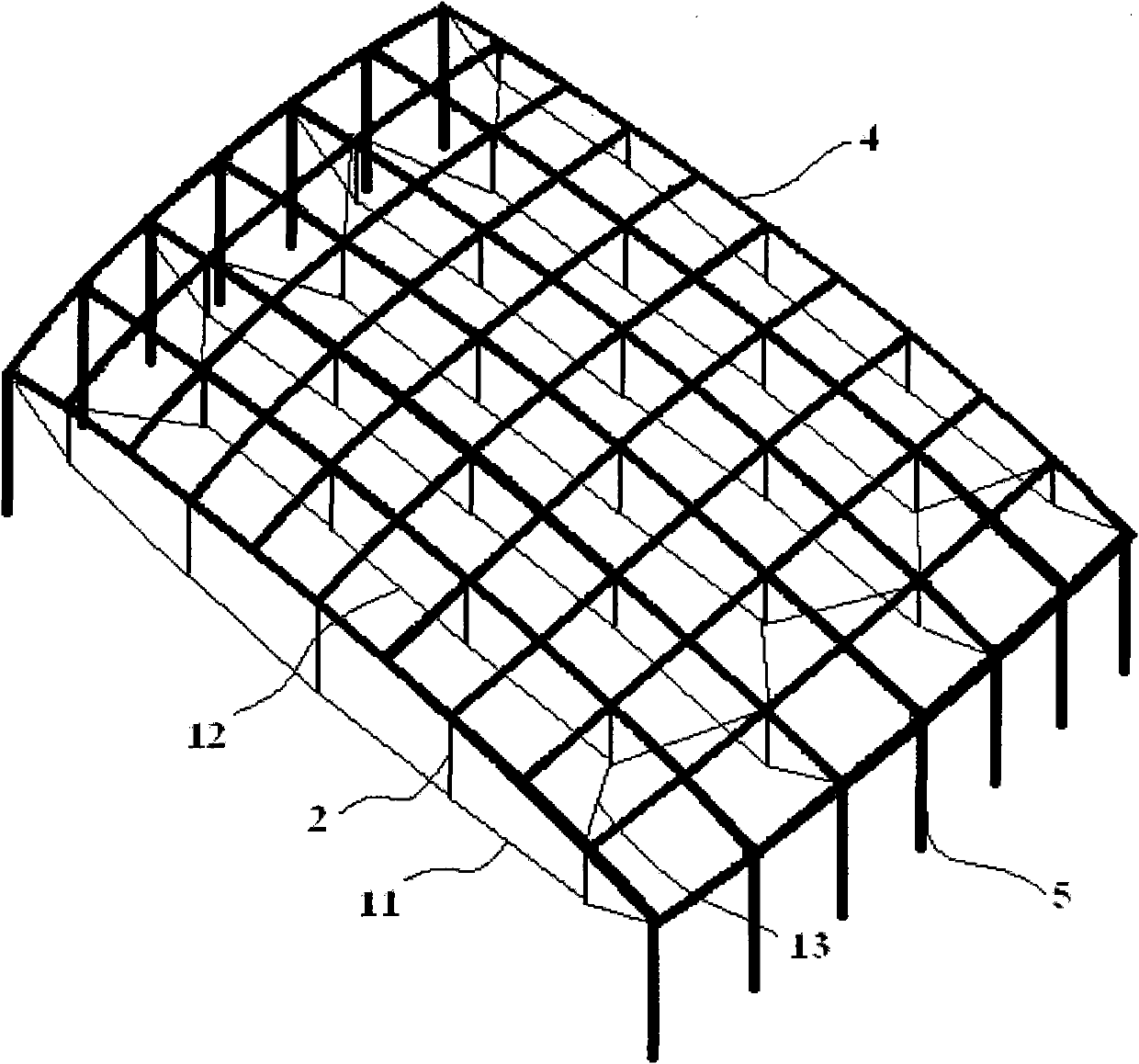

[0042] Embodiments of the present invention provide a suspensive beam structure, such as Figure 2 to Figure 5 As shown, it includes a grid beam 4 on the upper part and a chord structure connected to the lower part of the grid beam 4 .

[0043] The grid beam 4 is preferably a single-layer grid beam, such as a two-way orthogonal vertically placed continuous grid beam, and its two ends are used to be connected to vertical members 5 such as columns and walls, or to be connected to horizontal members. The member should have a large lateral stiffness to ensure that it can bear the tension exerted by the cable.

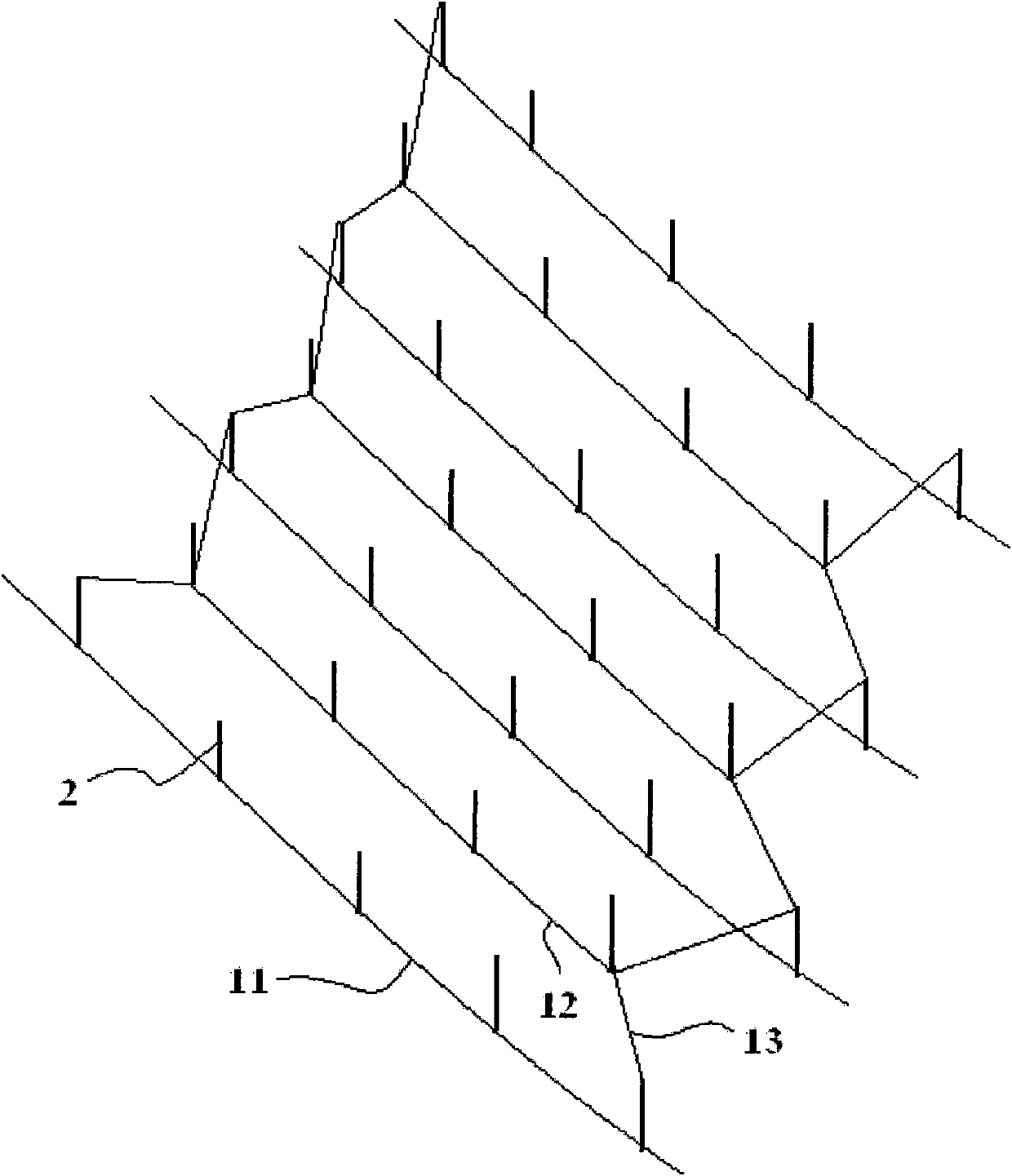

[0044] The suspensive structure includes a plurality of main cables 11 extending from one end of the grid beam 4 to the other and distributed side by side. connected, or connected with the horizontal member), and the projection of each main cable 11 on the horizontal plane is parallel to the first direction, and the first direction is preferably parallel to the length dire...

Embodiment 2

[0052] An embodiment of the present invention provides a suspension beam structure, which is similar to the suspension beam structure in Embodiment 1. The difference is that the suspensive beam structure of this embodiment also includes a plurality of cable-stayed members 3, which can be cable-stayed rods (such as cable-stayed bar steel) or cable-stayed cables (such as cable-stayed steel cables), the lower end of which is Connect the lower end node of a strut 2 (that is, the position where the strut 2 is connected to the main cable 11 or the secondary cable 12), and the upper end is connected to the upper node of another strut 2 (that is, the strut 2 and the grid beam 4 connected position), and the projection of the included angle between the cable-stayed member 3 and the main cable 11 and the secondary cable 12 on the horizontal plane is greater than 0 degrees and less than 90 degrees, that is to say, the cable-stayed member 3 is relatively Cable 12 is arranged obliquely.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com