Water circulating system of dyeing and finishing machine

A water circulation and mechanical technology, applied in the field of water circulation system, can solve the problems of aging of circuit control components, troublesome repair and maintenance, high cost, etc., achieve good distribution effect, and solve the effect of uneven distribution of dye liquor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

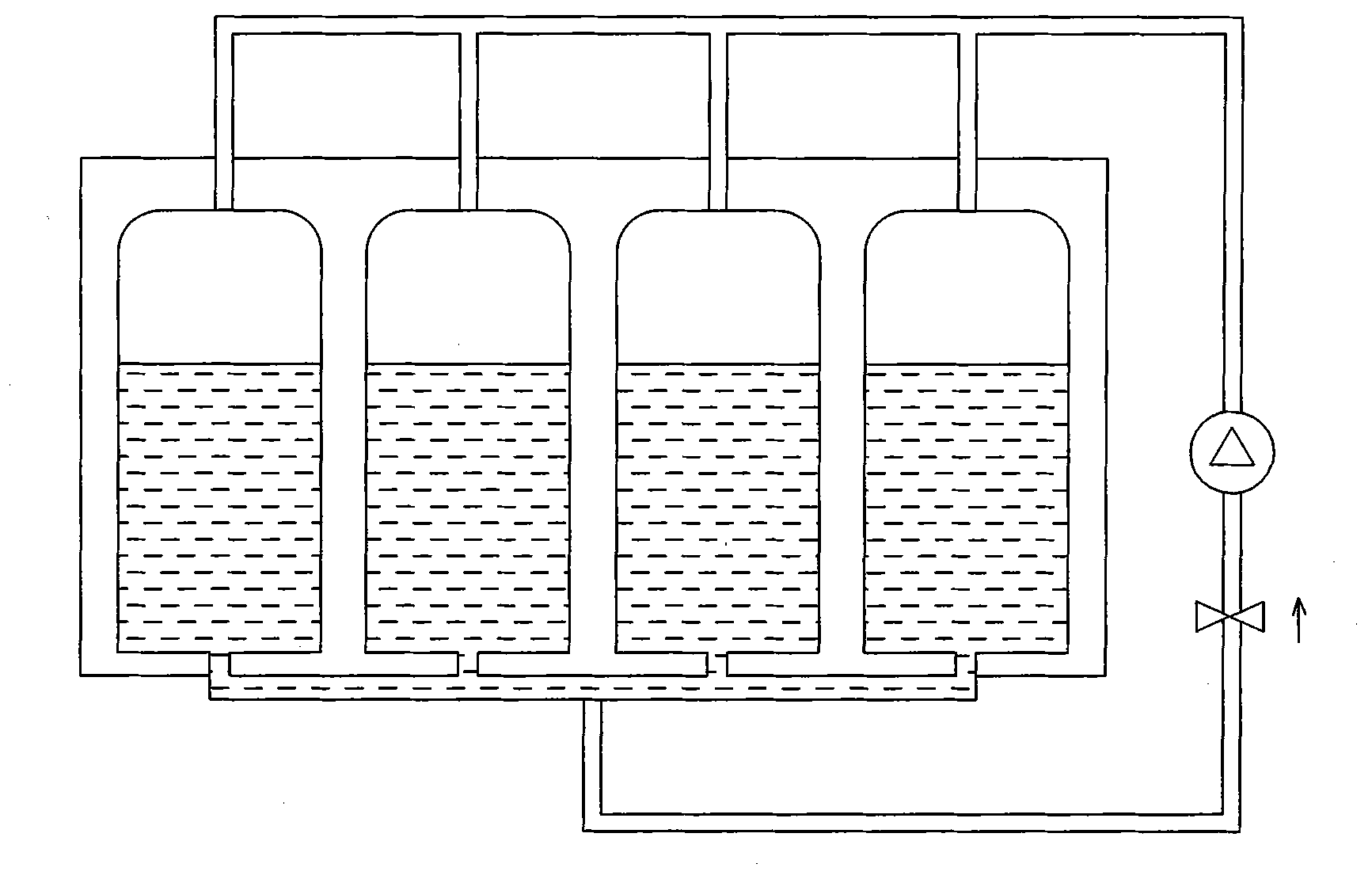

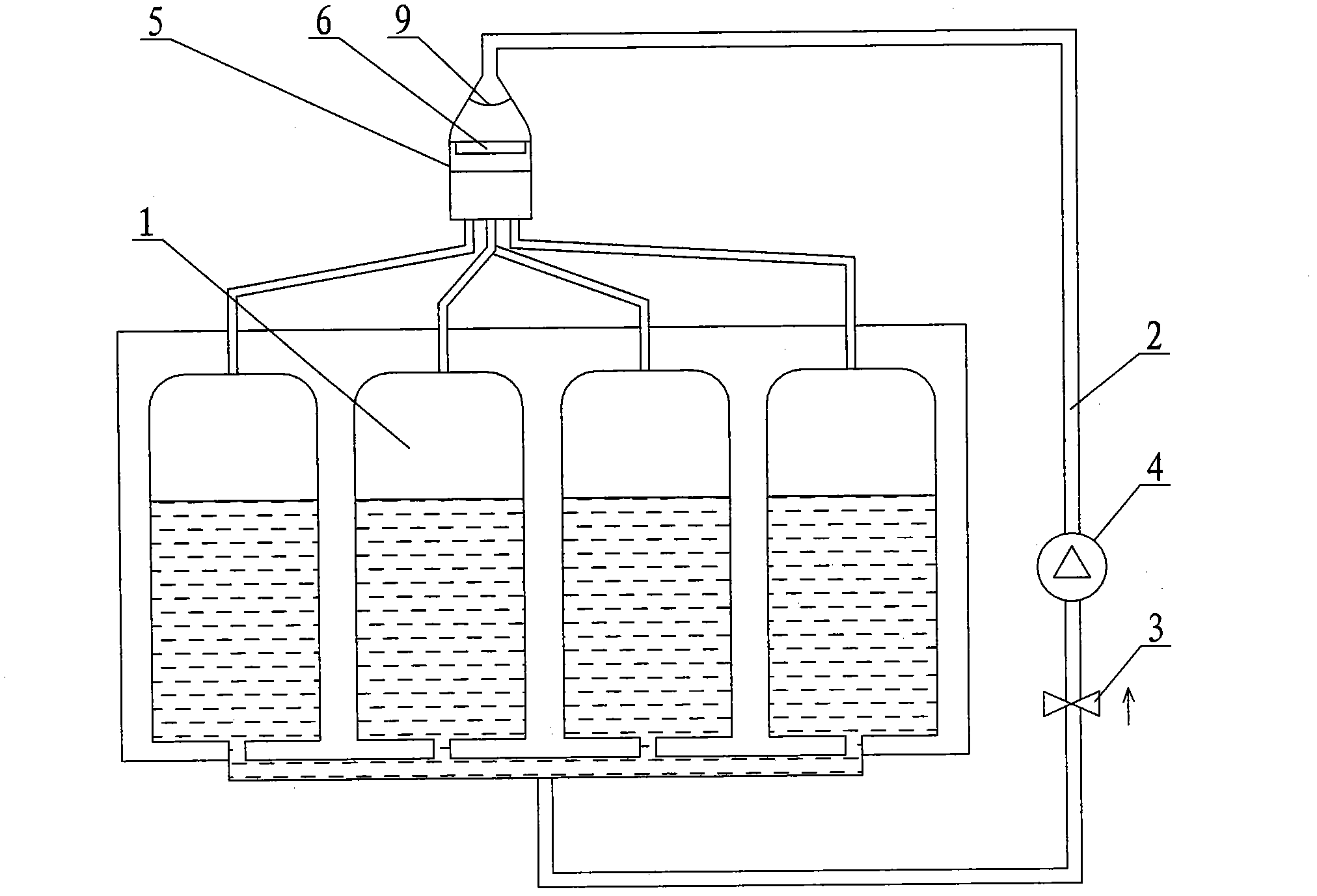

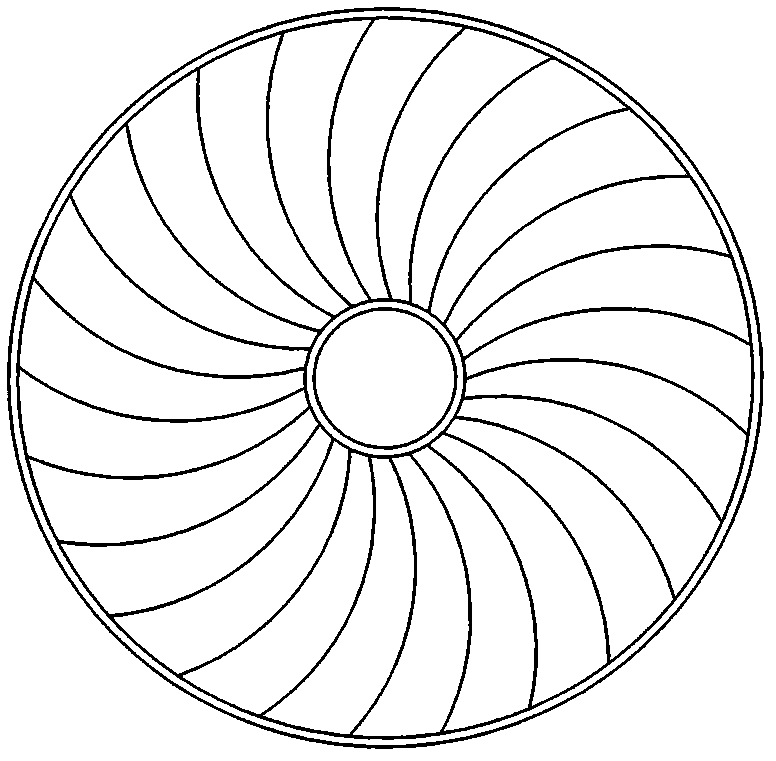

[0018] like Figure 2-4 As shown, the dyeing and finishing mechanical water circulation system of the present invention includes a plurality of discrete dyeing cylinders 1 arranged in a straight line, the upper center of each dyeing cylinder 1 is provided with a dye solution inlet, and the lower center of each dyeing cylinder 1 is provided with There is a dye solution outlet, and the upper and lower parts of the dyeing cylinder 1 are respectively connected to the same circulation pipeline 2, and a check valve 3 and a hydraulic pump 4 are arranged on the circulation pipeline 2, and the water circulation pipeline 2 and the The position where each dyeing cylinder 1 is connected is provided with an airtight separation cylinder 5. The separation cylinder 5 is arranged vertically. On the road 2, the connection port is an upright conical device, and an arc-shaped filter screen 9 is arranged at the lower part of the connection port, and a rotatable circular water wheel 6 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com