Device for knocking and splitting diamond synthetic block

A technology for synthesizing blocks and diamonds, which is used in fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of small fragments of diamond particles falling to the ground and being lost, cylinders are not easy to be symmetrically smashed, and work efficiency is low. , to achieve the effect of low labor intensity of workers, avoiding diamond loss and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

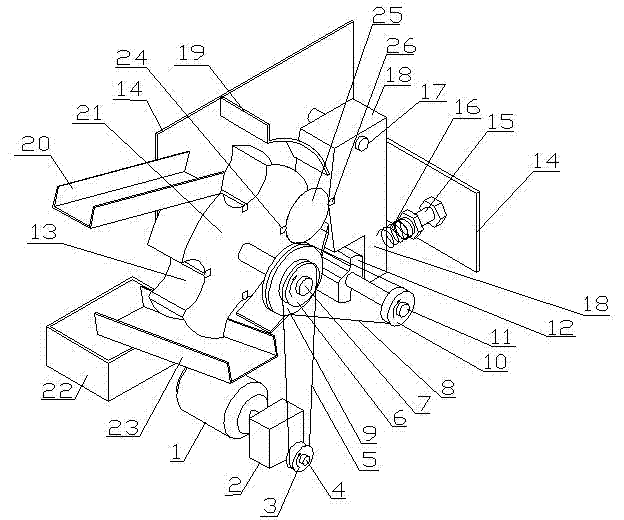

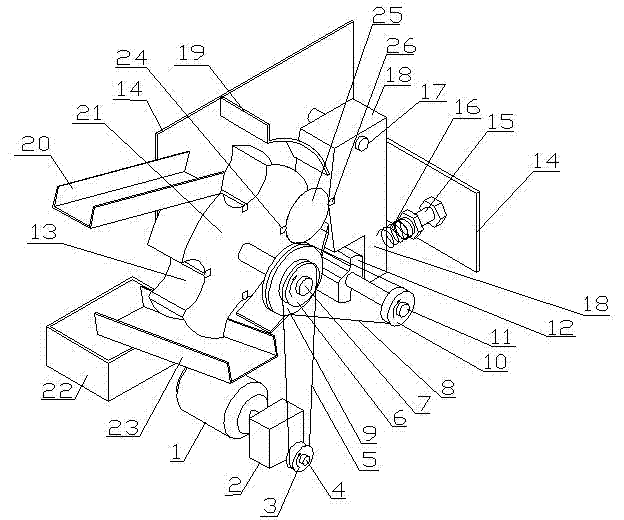

[0018] like figure 1 The shown splitting device for diamond synthetic blocks comprises a frame 14 on which a main shaft 7, a cam shaft 11 and a pin shaft 17 are arranged, the main shaft 7 and the cam shaft 11 are rotatable, and the pin shaft 17 is fixed. set up. The main shaft 7 is provided with a rotary table 21, the rotary table 21 is cylindrical, and the circumferential surface of the rotary table 21 is provided with an arc groove 13 compatible with the synthesis block 25, and the bottom of the arc groove 13 is installed There is an inner knife block 24, and the inner knife block 24 is a cemented carbide knife block. For the convenience of feeding and discharging, a feed chute 20 is provided above the rotary table 21, a discharge chute 23 is provided below, and a receiving box 22 is provided at the outlet of the discharge chute 23, and the feed chute 20 and the discharge chute 23 are arranged obliquely , can realize automatic feeding and discharging. The camshaft 11 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com