Dieless cold spinning one-step forming device and method for end enclosure

A cold spinning and sealing head technology, which is applied in the field of spinning devices, can solve the problems of complicated procedures and low efficiency, and achieve the effects of improving the deformation state, reducing the number of spinning passes, and increasing the amount of plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

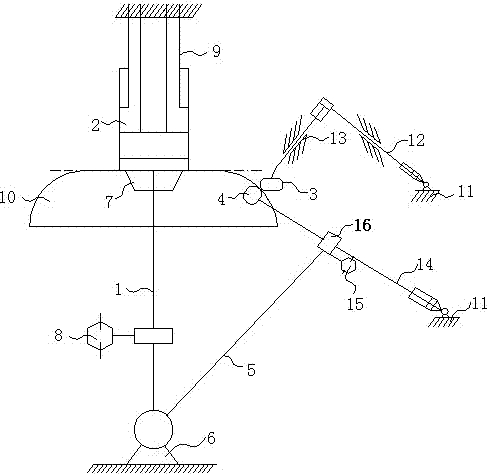

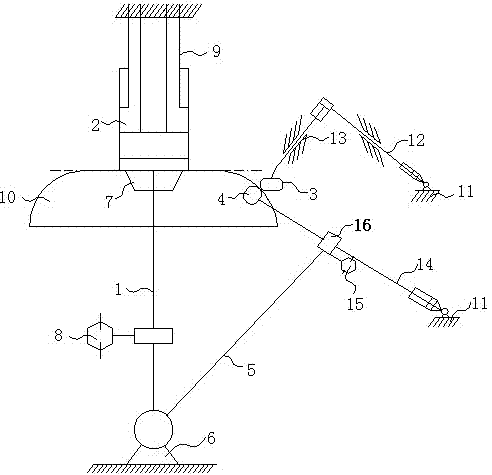

[0009] The one-step forming device of headless tire cold spinning of the present invention is composed of a main shaft 1, a hydraulic jacking shaft 2, a spinning roller 3, a forming roller 4, and an arc regulating arm 5. The lower end of the main shaft 1 is supported on the frame 6, and the upper end is movably fitted with a tray 7. The main shaft 1 is mechanically connected with the drive motor 8, and the top beam 9 of the frame above the coaxial center of the main shaft 1 is vertically provided with a hydraulic jack. The tightening shaft 2 clamps the circular plate blank 10 between the hydraulic jacking shaft 2 and the pallet 7 of the main shaft 1; the horizontal hydraulic arm 12 of the spinning roller is connected to the upper part of the side column of the frame, and its upper end is connected with the longitudinal hydraulic pressure of the spinning roller. The tail end of the arm 13 is fixedly connected at a knuckle, and the lower end of the longitudinal hydraulic arm 13 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com