Novel anti-back-suction device for high-speed turbine handpiece

A turbine and mobile phone technology, applied in medical science, dentistry, dental tools, etc., can solve the problems of unsatisfactory anti-suction effect, pollution, and large back-suction effect, and achieve a simple structure, high-efficiency use, and elimination of the back-suction effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

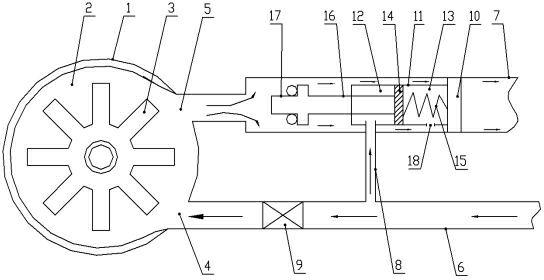

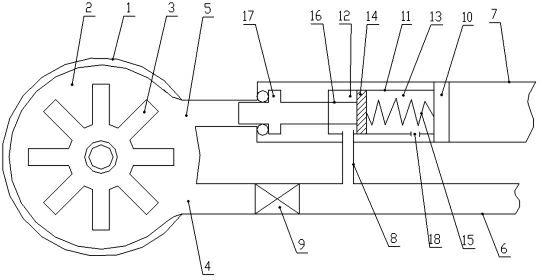

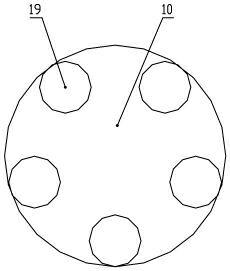

[0017] like figure 1 , figure 2 and image 3 As shown, the novel non-return suction device of the high-speed turbine handpiece of the present invention comprises a machine head 1, the inner cavity 2 of the machine head 1 is provided with a rotating wind wheel assembly 3, and the side of the machine head 1 is provided with an air inlet 4 and an air return port 5. The air inlet 4 is set in the tangential direction of the edge of the inner chamber 2. The air inlet 4 and the air return port 5 are respectively connected with the air intake pipe 6 and the air return pipe 7. The air return pipe 7 is provided with a valve that can block or open the air return port 5. A control valve, a control air pipe 8 is arranged between the control valve and the air intake pipe 6, and a one-way air intake valve 9 is arranged in the air intake pipe 6, and the one-way air intake valve 9 is located between the air inlet 4 and the control air pipe 8. The machine head 1 and the wind wheel assembly 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com