Material transport vehicle and unloading monitoring device thereof

A monitoring device and technology for transport vehicles, which are used in transportation and packaging, traffic control systems for road vehicles, loading/unloading, etc., can solve the problems of fluctuating vehicle costs, difficult and time-consuming inspections, and improve production efficiency. Protect the company's interests and increase profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

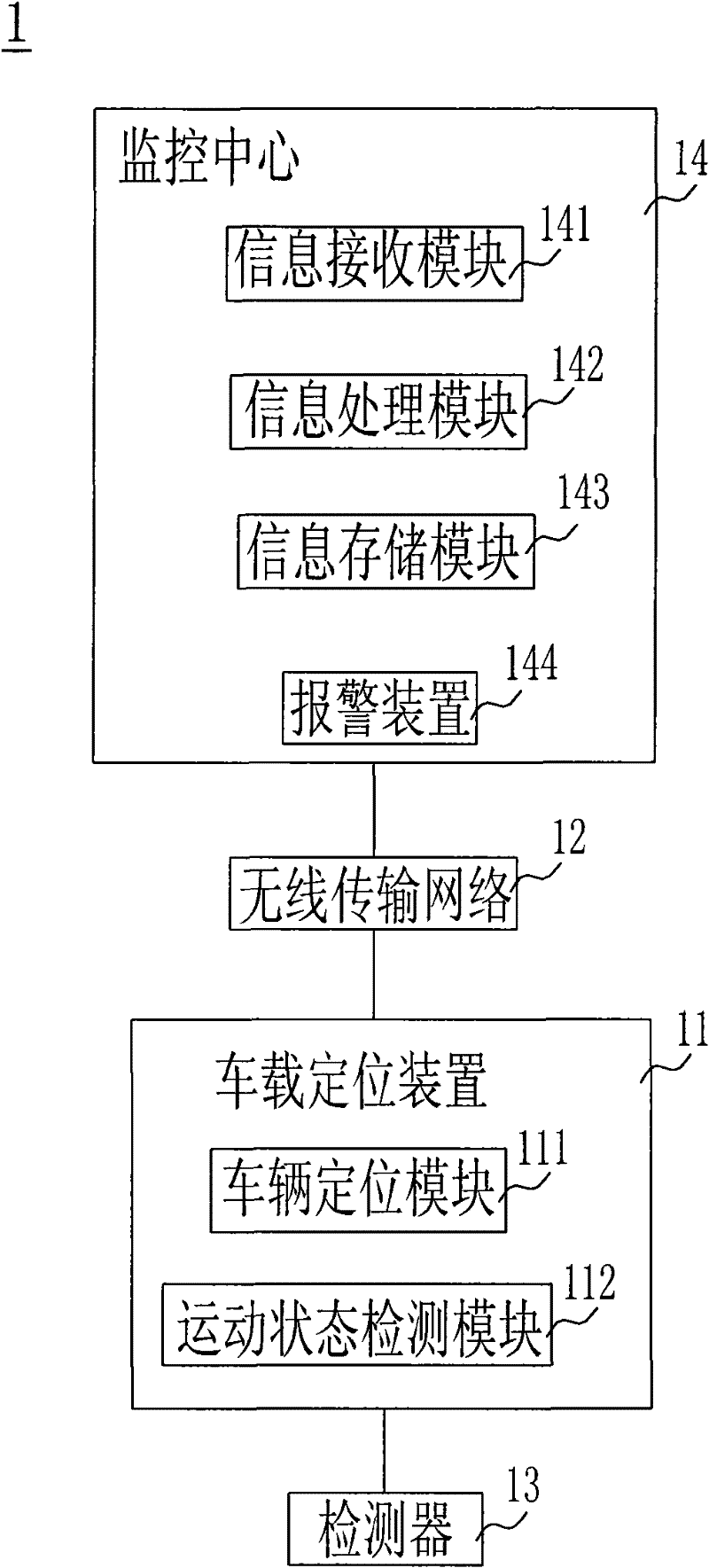

[0057] see figure 2 , figure 2 It is a block diagram of the discharge control device of the present invention. The unloading monitoring device 1 of the material transport vehicle of the present invention includes: an on-board detector 13, which is arranged on the material transport vehicle and is used to detect the movement of the cargo box and / or the loaded material of the material transport vehicle state, and convert the motion state into a motion state electrical signal output; the vehicle positioning device 11 is arranged on the material transport vehicle and is connected with the vehicle detector 13, including: a vehicle positioning module 111, used to realize the Real-time positioning of the material transport vehicle, and output the position signal of the material transport vehicle; the motion state detection module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com