System and method for carrying out automated quantitative management on glass substrates

A glass substrate and management system technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of glass substrates that do not achieve automatic quantitative management, decreased work efficiency, and severe mechanical wear, etc. To achieve the effect of improving automatic management functions and equipment operation efficiency, reducing failure rate and reducing mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

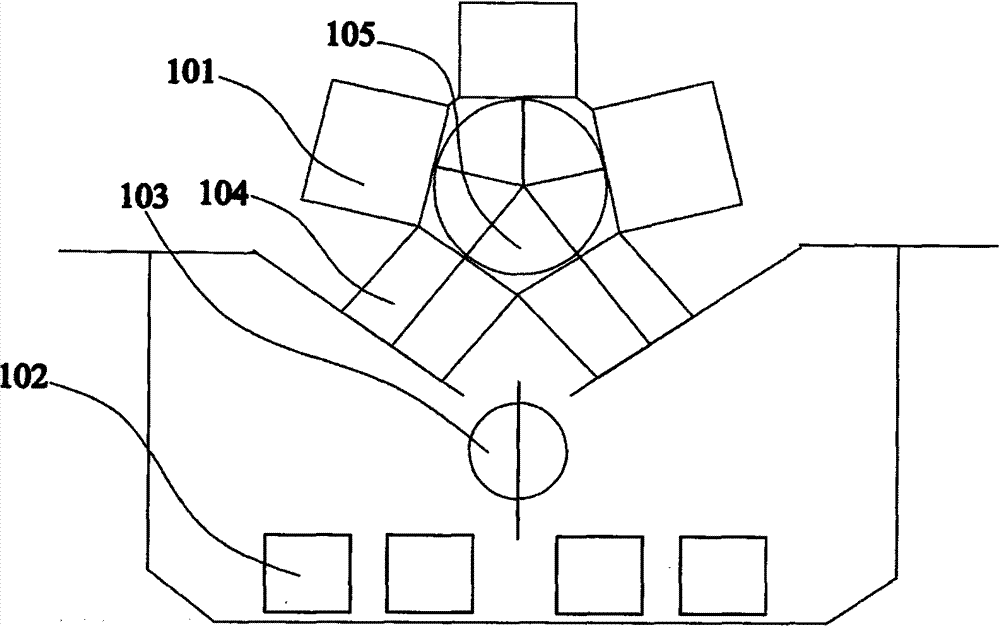

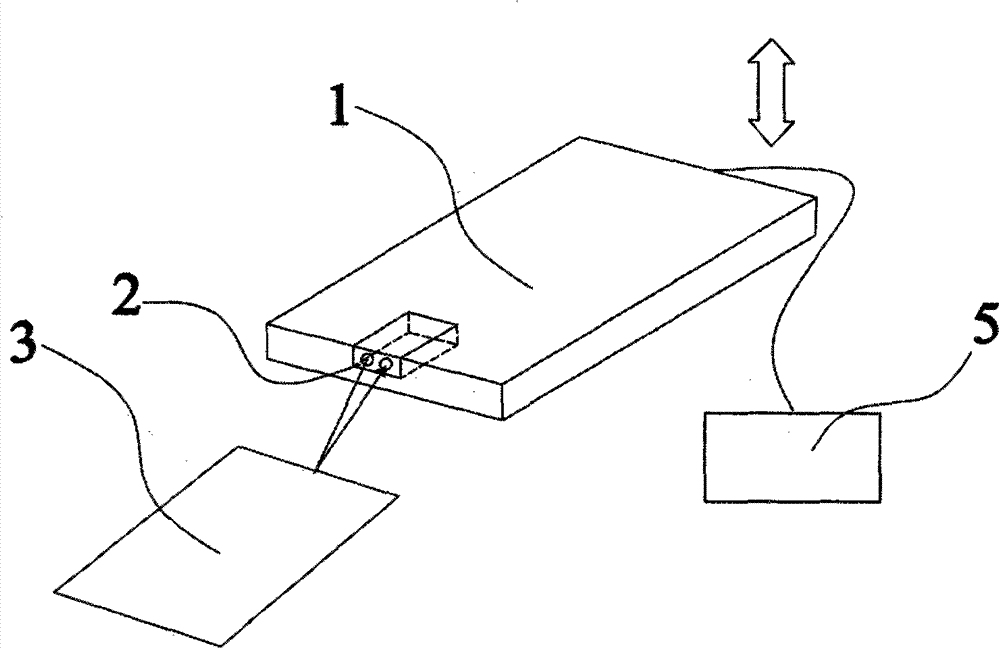

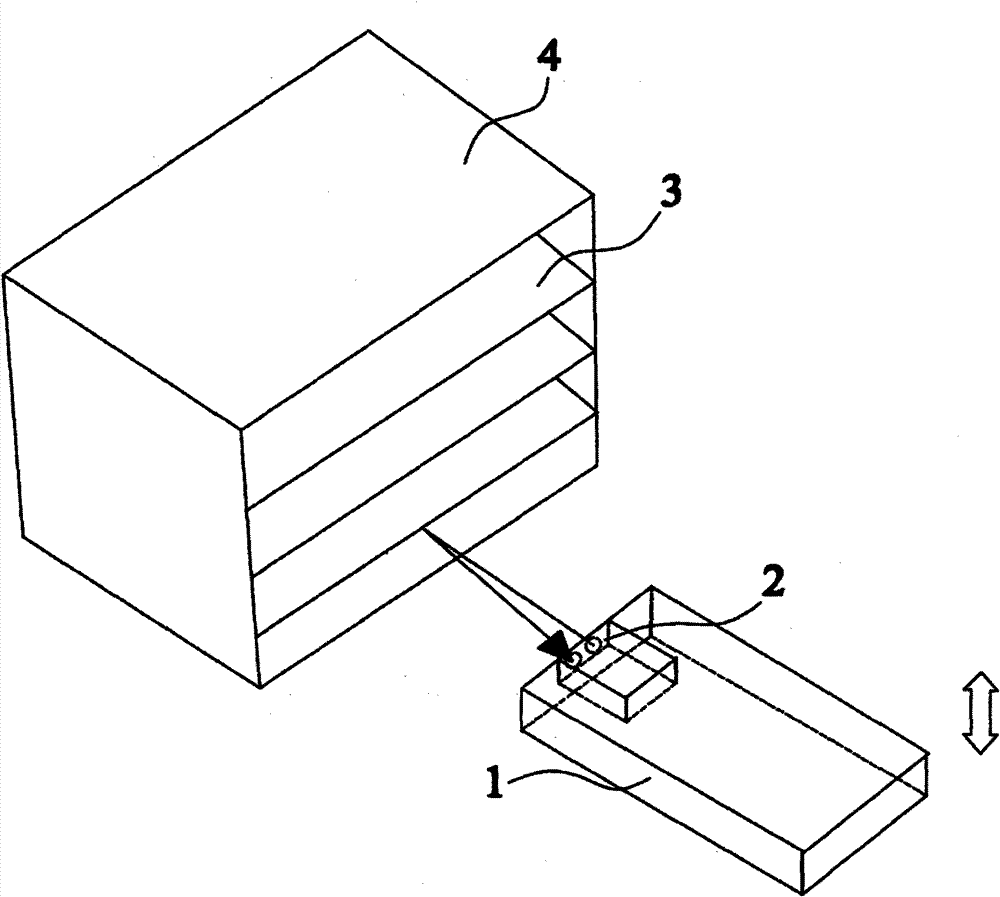

[0069] see figure 2 As shown, the glass substrate automatic quantitative management system in the solar thin film cell manufacturing equipment is mainly aimed at the glass substrate box 4 ( Figure 3 ~ Figure 5 Shown in ), the automatic quantitative management of the glass substrate is carried out, wherein, the automatic quantitative management system of the glass substrate mainly includes:

[0070] (1) glass substrate handling device 1;

[0071] (2) The photoelectric sensor device 2 is arranged on the glass substrate handling device 1, preferably the front end, for detecting the reflected light of the side wall of the glass substrate 3;

[0072] (3) The control device 5 is connected to the glass substrate conveying device 1 and the photoelectric sensor device 2 respectively, and is used to control the movement of the glass substrate conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com