Current detector

A technology of current detector and current detection circuit, applied in the direction of voltage/current isolation, measuring current/voltage, instruments, etc., can solve problems such as current detection error, and achieve the effect of reducing current detection error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

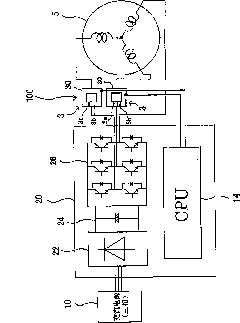

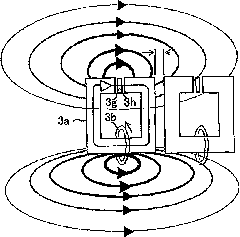

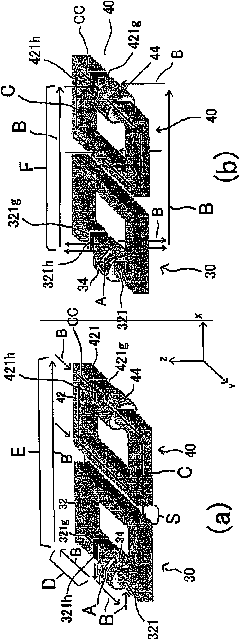

[0046] image 3 and Figure 4 It is a diagram showing a schematic configuration of a current detector according to Embodiment 1 of the present invention. image 3 It is a diagram showing a schematic structure consisting of a core, a coil, and a Hall element. (a) is a diagram showing the core, coil, Hall element, and leakage flux on the XY plane, and (b) is showing the leakage flux on the XZ plane. common diagram. Figure 4 It is a diagram that further includes a schematic structure of a board, embedded pins (On board pins), lead wires, and signal lines. (a) is a diagram showing magnetic flux leakage on the XY plane, and (b) is a diagram showing magnetic flux leakage on the XZ plane. .

[0047] Such as image 3 (a), (b) and Figure 4 As shown in (a) and (b), the current detector of this embodiment has the following configuration: the first current detection circuit 30 and the second current detection circuit 40 are arranged in parallel on a substrate (the substrate of the ...

Embodiment 2

[0058] Figure 5 and Figure 6 It is a diagram showing a schematic configuration of a current detector according to Embodiment 2 of the present invention. Figure 5 It is a diagram showing a schematic structure consisting of a core, a coil, and a Hall element. (a) is a diagram showing the core, coil, Hall element, and leakage flux on the XY plane, and (b) is showing the leakage flux on the XZ plane. common diagram. Figure 6 It is a diagram showing a schematic structure further including a substrate, embedded pins, leads, and signal lines, (a) is a diagram showing leakage flux on the XY plane, and (b) is a diagram showing leakage flux on the XZ plane.

[0059] Such as Figure 5 (a), (b) and Figure 6 As shown in (a) and (b), the current detector of this embodiment has the following structure: the first current detection circuit 50 and the second current detection circuit 60 are formed on a substrate (the substrate of the current detector), a bobbin, a frame or They are ar...

Embodiment 3

[0070] Figure 7 and Figure 8 It is a diagram showing a schematic configuration of a current detector according to Embodiment 3 of the present invention. Figure 7 It is a diagram showing a schematic structure consisting of a core, a coil, and a Hall element. (a) is a diagram showing the core, coil, Hall element, and leakage flux on the XY plane, and (b) is showing the leakage flux on the XZ plane. common diagram. Figure 8 It is a diagram showing a schematic structure further including a substrate, embedded pins, leads, and signal lines, (a) is a diagram showing leakage flux on the XY plane, and (b) is a diagram showing leakage flux on the XZ plane.

[0071] This embodiment is characterized in that the structure of the first embodiment in which the Hall element in the second current detection circuit is separated from the leakage magnetic flux generating part in the first current detection circuit as described above has an angle (θ = 90° °) The structure of embodiment 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com