Control device for AC rotary motor and control device for electric power steering system

A technology for rotating electrical machines and control devices, which is applied in AC motor control, control system, motor control and other directions, can solve the problem of phase current value that cannot be detected, and achieve the effect of reducing current detection errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

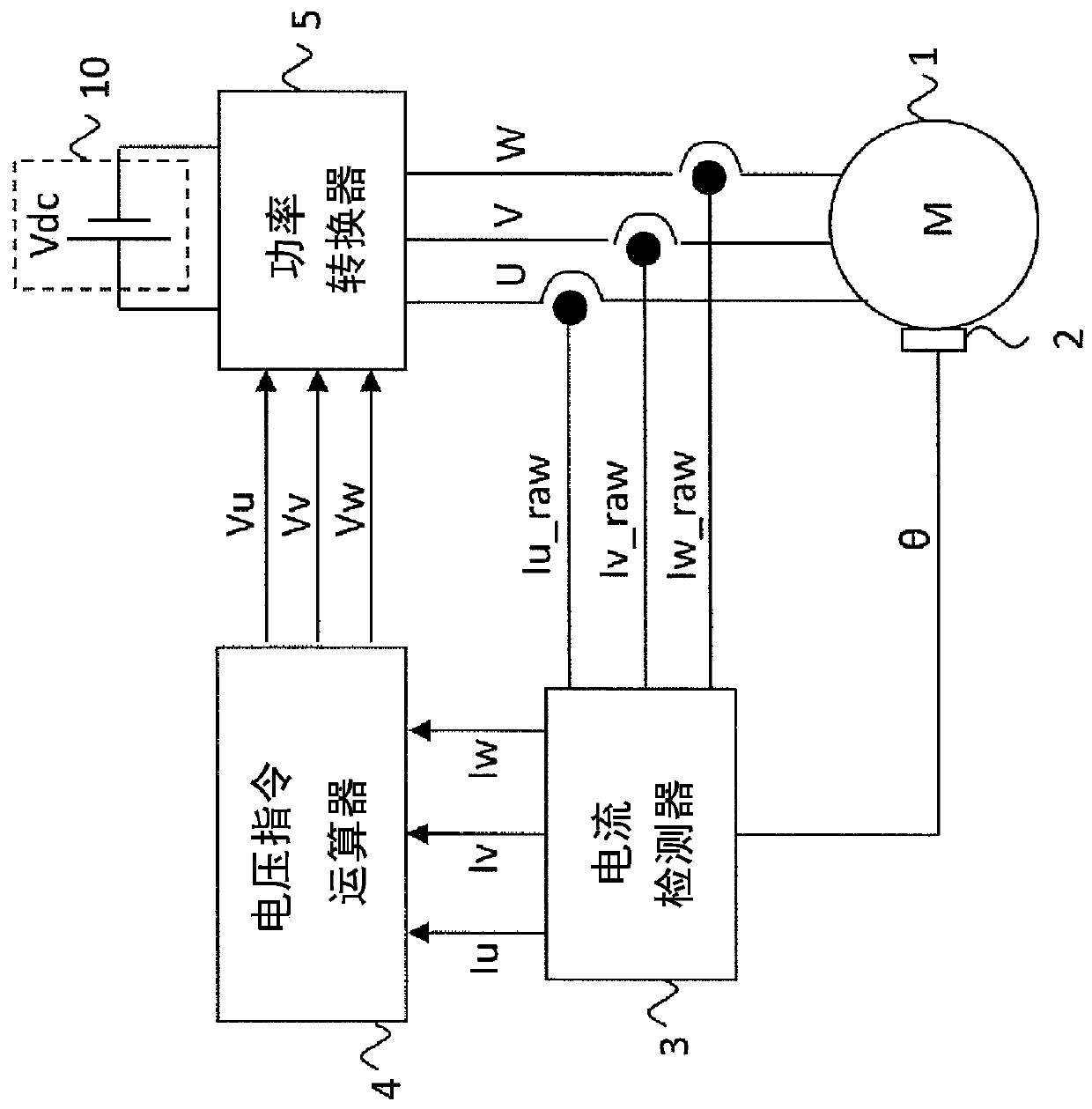

[0027] figure 1 It is a diagram showing the overall configuration of the control device for an AC rotating electrical machine according to Embodiment 1 of the present invention. figure 1 Among them, the AC rotating electrical machine 1 is a permanent magnet type synchronous rotating electrical machine having three-phase windings U, V, W. In addition, in Embodiment 1, a case where a permanent magnet type synchronous rotating electrical machine is used as the AC rotating electrical machine 1 is described, but the AC rotating electrical machine 1 may be a field winding type synchronous rotating electrical machine.

[0028] The DC power supply 10 outputs a DC voltage Vdc to the power converter 5 described later. The DC power supply 10 includes all devices that output a DC voltage, such as a battery, a DC-DC converter, a diode rectifier, and a PWM rectifier.

[0029] The angle detector 2 is a position detector such as a Hall element, a resolver, or an encoder, and detects the r...

Embodiment approach 2

[0088] In the first embodiment above, the above-mentioned formula (5) using an approximate formula of a trigonometric function for a small amount of angle change is used in the estimation calculation. However, in the high-speed rotation region where the angle change is larger, the larger Δθ is, the larger the approximation error is.

[0089] Therefore, by applying the following equation (11) in consideration of the second and second terms in the Taylor expansion as an approximate expression of COS, errors can be suppressed even at high-speed rotation.

[0090] 【Mathematical formula 10】

[0091]

[0092] Figure 7 It is a graph comparing the approximation error with respect to the change in the angle change amount Δθ when using the formulas (5) and (11) in Embodiment 2 of the present invention, the horizontal axis is Δθ [deg], and the vertical axis is the approximation error . In the case of a change of 10 degrees, if the above formula (5) is applied, an approximation err...

Embodiment approach 3

[0104] In Embodiment 1 and Embodiment 2 above, a control device for an AC rotating electric machine having a three-phase winding has been described. On the other hand, in the third embodiment, the AC rotating electrical machine to be applied is generalized as an AC rotating electrical machine having x-phase windings (x is a natural number greater than or equal to 3), and the application of the present invention is based on this. The method of estimation calculation processing will be described in detail.

[0105] Figure 9 It is a diagram showing the overall configuration of a control device for an AC rotating electrical machine according to Embodiment 3 of the present invention. Figure 9 Among them, the AC rotating electrical machine 1a is a permanent magnet type synchronous rotating electrical machine having an x-phase winding. In addition, in Embodiment 3, a case where a permanent magnet type synchronous rotating electrical machine is used as the AC rotating electrical m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com