Universal sub-control low-carbon water nozzle

A carbon water nozzle and all-round technology, which is applied to injection devices, multi-way valves, engine components, etc., to reduce environmental pollution sources and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

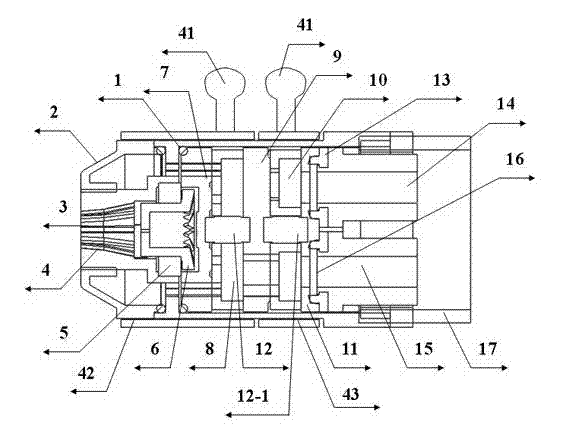

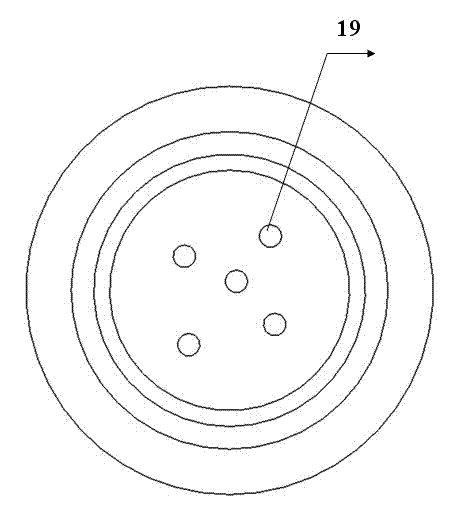

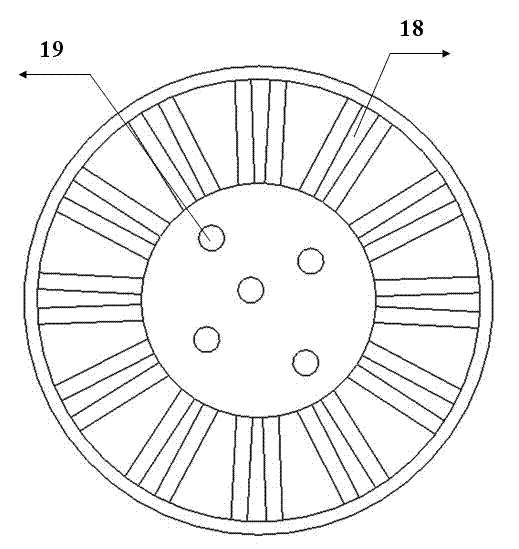

[0028] Such as figure 1 It shows an embodiment of the all-purpose sub-control low-carbon water nozzle of the present invention, including a housing 1, a cover 2 is provided at the front of the housing 1, a water outlet 3 is provided in the middle of the cover 2, and the inner cavity of the water outlet 3 Ribs 4 are arranged on the surface, the diameter of water outlet 3 is less than 12 mm, and the length is less than 10 mm. Close to the rear of the water outlet 3, a water outlet core 6 is inserted in the bearing 5, and the rear of the water outlet core 6 is sequentially equipped with a guide plate 7, a water control plate 8, a sealing plate 9, a temperature control plate 10, a water inlet plate 11, and a compression plate. Sheet 16, the above-mentioned valve sheets are combined into a combined valve sheet. The center of the deflector 7, the water control sheet 8 and the sealing sheet 9 is provided with a first center pin 12, the flow guide sheet 7, the water control sheet 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com