In-situ heat injection steeping control aqueous dissolution exploitation method of glauberite ore

A mining method, glauberite technology, applied in the direction of mining fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of high cost, difficult to maintain pressure, low efficiency, etc., and achieve energy saving, high-efficiency soaking and dissolution, and improved The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

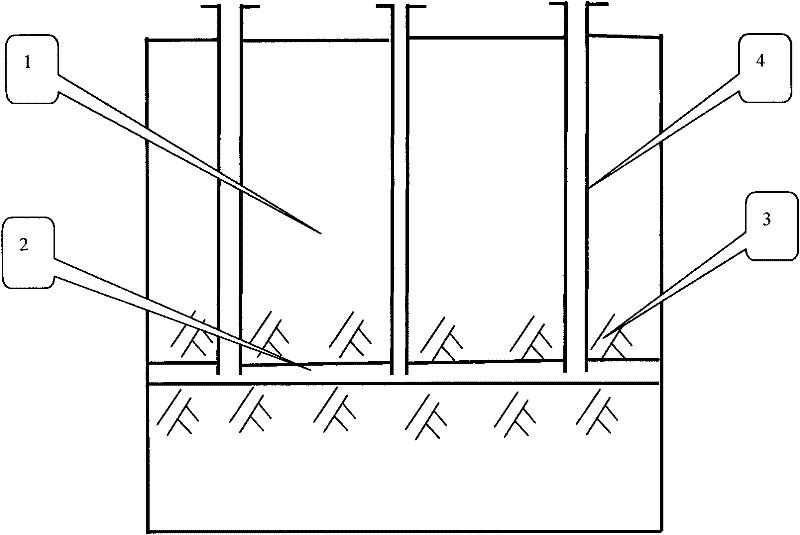

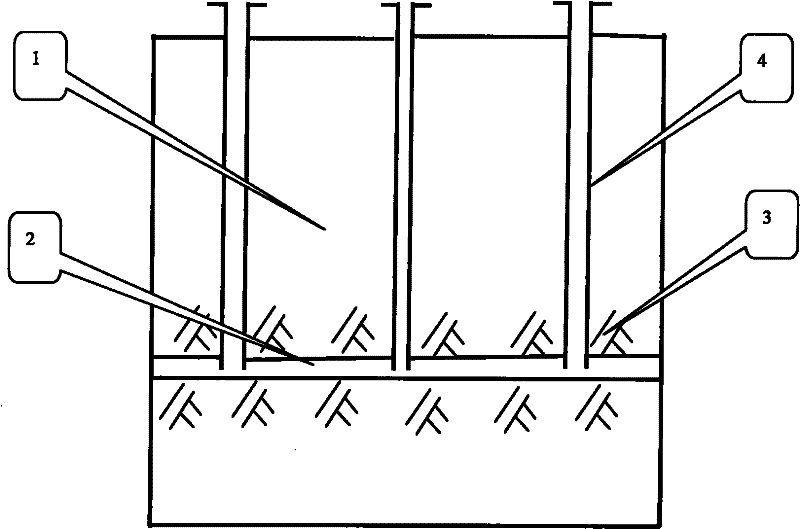

[0020] Such as figure 1 , 2 Shown, a kind of glauberite ore in situ heat injection soaking control water solution mining method, the specific implementation steps are:

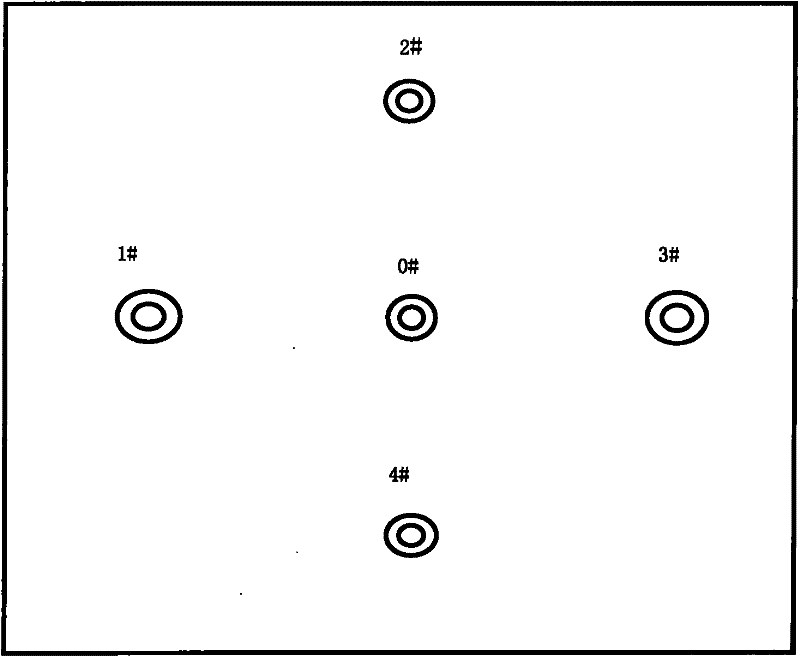

[0021] (1) According to the surface conditions and the buried depth of the ore deposit, select a scientific well spacing (100-500m) to arrange a reasonable well pattern (the well pattern consists of 5 wells: 0 # For water injection well; 1 # ,2 # 、3 # 、4 # for producing wells);

[0022] (2) Select middle 0 # well as a frac well, 1 # ,2 # 、3 # 、4 # The well is used as the target well, and the high-pressure hydraulic fracturing connection is implemented, and the reverse fracturing is performed by switching the fracturing well and the target well, or closing the initial fracturing well, and mutual pressure is applied between the target wells, so that all 5 wells are connected;

[0023] (3) After all wells are connected to the bottom in the glauberite layer, waste hot water from the chemical workshop is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com