Method for solidifying and processing soft soil foundation by draining water from plant cushion layer in vacuum

A technology of vacuum drainage and soft soil foundation, which can be applied in the fields of soil protection, infrastructure engineering, construction, etc., can solve the problem of reduction, and must go to farther river bottoms and seabeds to obtain, which cannot meet short-term land use needs, and the interval is long. and other issues to achieve low cost, short construction period and good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This example is a soft soil foundation treatment experiment of dredging filling in Shanghai area.

[0050] It has been 2 years since the site was filled and the treatment area of the test area is 625m 2 (25m×25m), the thickness of the dredger fill is about 3.5m, and the permeability coefficient is less than 10-6cm / s. The current ground is covered with reeds and accumulated water. The bearing capacity of the foundation is 15Pa, and the equipment cannot enter the site. The implementation process of the test area is as follows:

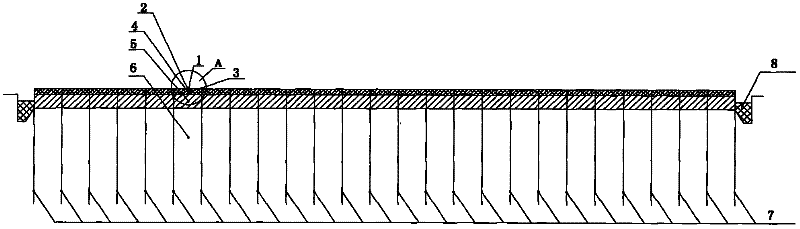

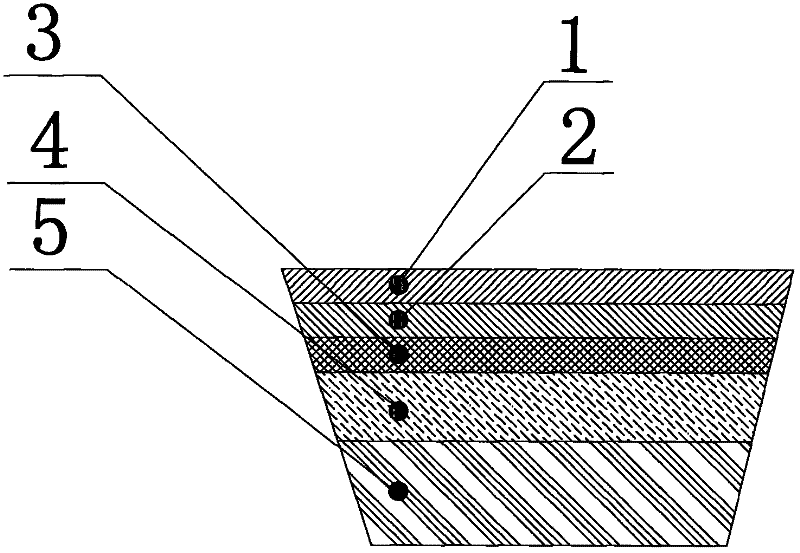

[0051] 1) Manually lay down the reeds in the field in the same direction, and roll them flat, and at the same time detect the thickness of the dredged fill soil to be treated;

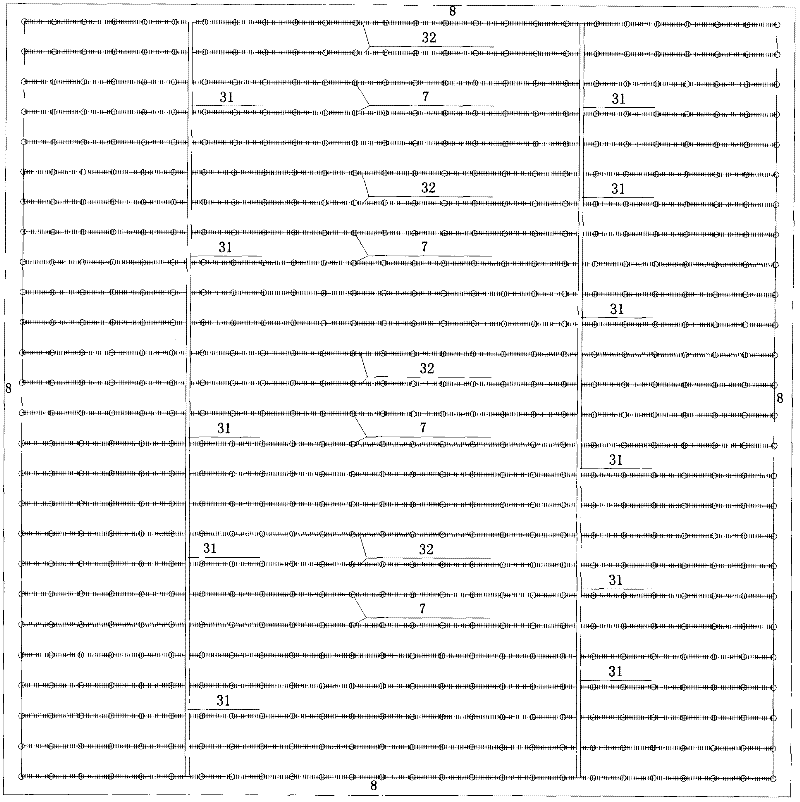

[0052]2) Manually insert plastic drainage boards vertically. The drainage boards are ordinary split type. The board spacing is 1.0m×1.0m. Side inclined pipe, etc.;

[0053] 3) Lay steel wire pipe main pipes horizontally and parallel at a distance of 12m, and lay an int...

Embodiment 2

[0060] This example is another site in the above ground treatment test, where the test parameters are different.

[0061] It has been 2 years since the site was filled by dredging. The treatment area of the test area is 625m2 (25m×25m), the thickness of the dredged fill is about 3.5m, and the permeability coefficient is less than 10-6cm / s. The force is 15Pa, and the equipment cannot enter the field. The implementation process of the test area is as follows:

[0062] 1) Manually lay down the reeds in the field in the same direction, and roll them flat, and at the same time detect the thickness of the dredged fill soil to be treated;

[0063] 2) Manually insert plastic drainage boards vertically. The drainage boards are ordinary split type. The board spacing is 1.2m×1.2m. Side inclined pipe, etc.;

[0064] 3) Lay steel wire pipe main pipes horizontally and parallel at a distance of 15m, and lay an integral drainage board horizontally at a distance of 1.2m between two rows of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bearing capacity of foundation | aaaaa | aaaaa |

| Bearing capacity of foundation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com