Special recyclable section for exhibition

A profile and thermoplastic technology, applied in the field of recyclable exhibition special profiles, can solve the problems of labor-intensive production site requirements, waste, unstable quality, etc., to save installation time and costs, avoid waste of resources, and simple surface treatment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

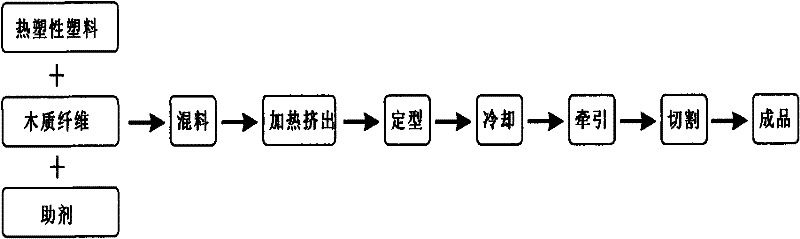

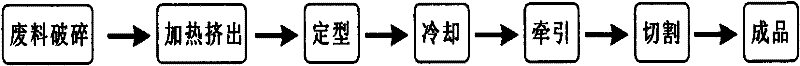

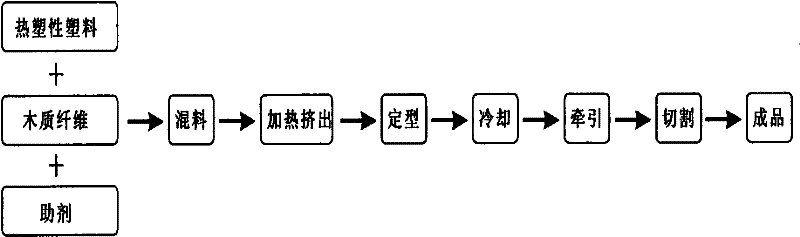

Method used

Image

Examples

Embodiment 1

[0039] Use a mixer to mix PVC resin, wood fiber, and additives at a mass ratio of 62:22:16, heat the mixture, extrude the mixture with an extruder, and shape the extruded mixture with a shaping table , cooled in a natural state for use, the material is pulled out to the cutting machine with a tractor, and cut into a specified size, and finally the finished product is obtained.

Embodiment 2

[0041] Use a mixer to mix PVC resin, wood fiber, and additives at a mass ratio of 63:23:14, heat the mixture, extrude the mixture with an extruder, and shape the extruded mixture with a shaping table , cooled in a natural state for use, the material is pulled out to the cutting machine with a tractor, and cut into a specified size, and finally the finished product is obtained.

[0042] The performance analysis of the finished recyclable special exhibition profiles prepared above is compared with the commonly used exhibition profiles, and the results are shown in Table 1:

[0043] performance item

[0044] Environmental pollution resistance

[0045] Table 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com