Up-spray laminar flow cooling device

A cooling device and spray layer technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of difficulty in ensuring the parallelism of the plunger and the plunger stuck, so as to achieve no sticking and stable operation. , The effect of reducing equipment configuration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

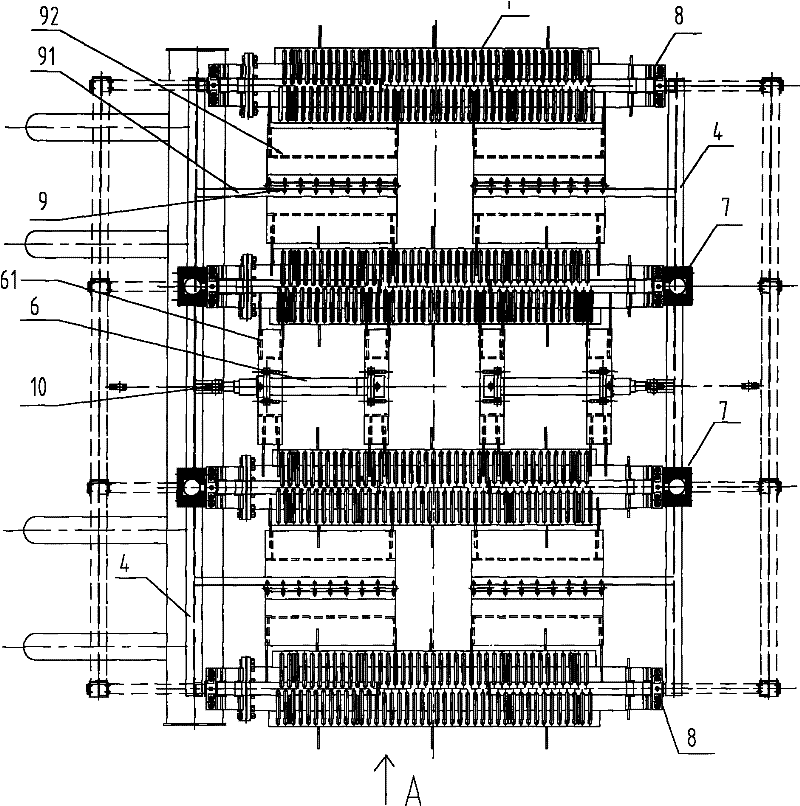

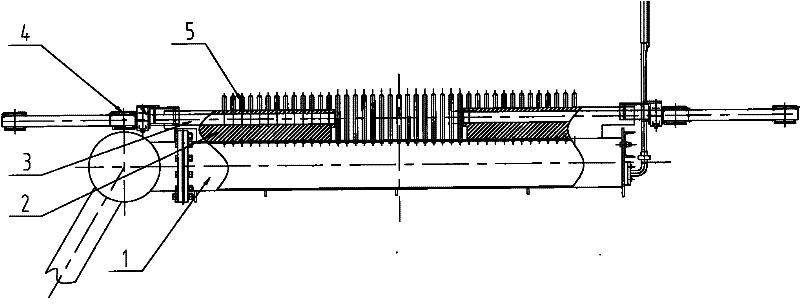

[0047] Attached below Figure 1-6 A preferred embodiment of the present invention is specifically introduced.

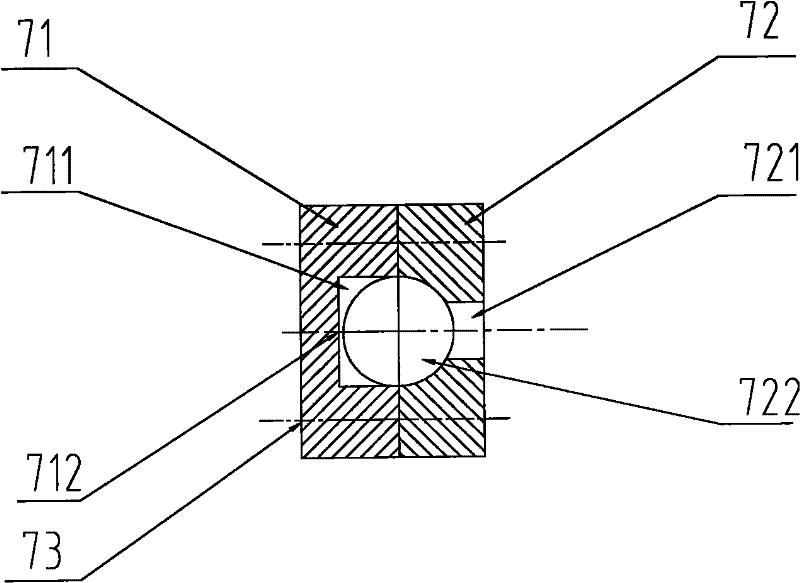

[0048] like figure 1 and figure 2 As shown, the upper spray laminar flow cooling device in the present embodiment includes several upper spray device groups, and each upper spray device group includes 4 upper spray devices, and each upper spray device includes: running along the vertical strip steel A header 1 with a fixed direction, a number of gooseneck nozzles 5 are evenly distributed on the header 1, a beam 2 is divided into two sections and arranged above both ends of the header 1, and a number of through holes are arranged on the beam 2 along the vertical direction for guiding Through the header 1 and each nozzle 5, the beam 2 is provided with a plunger hole along the horizontal direction, the plunger hole is connected with the through hole, the diameter of the plunger hole is greater than or equal to the diameter of the through hole, and the plunger 3 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com