A positive pressure capsule valve

A tube bag and tube pressure technology, which is applied to valves, instruments introduced into the body, etc., can solve the problems of inability to use heparin sealing method, cumbersome operation of medical staff, and microbial intrusion, etc., and achieves simple structure, which is beneficial to safety and avoids microbial intrusion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical solution of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings.

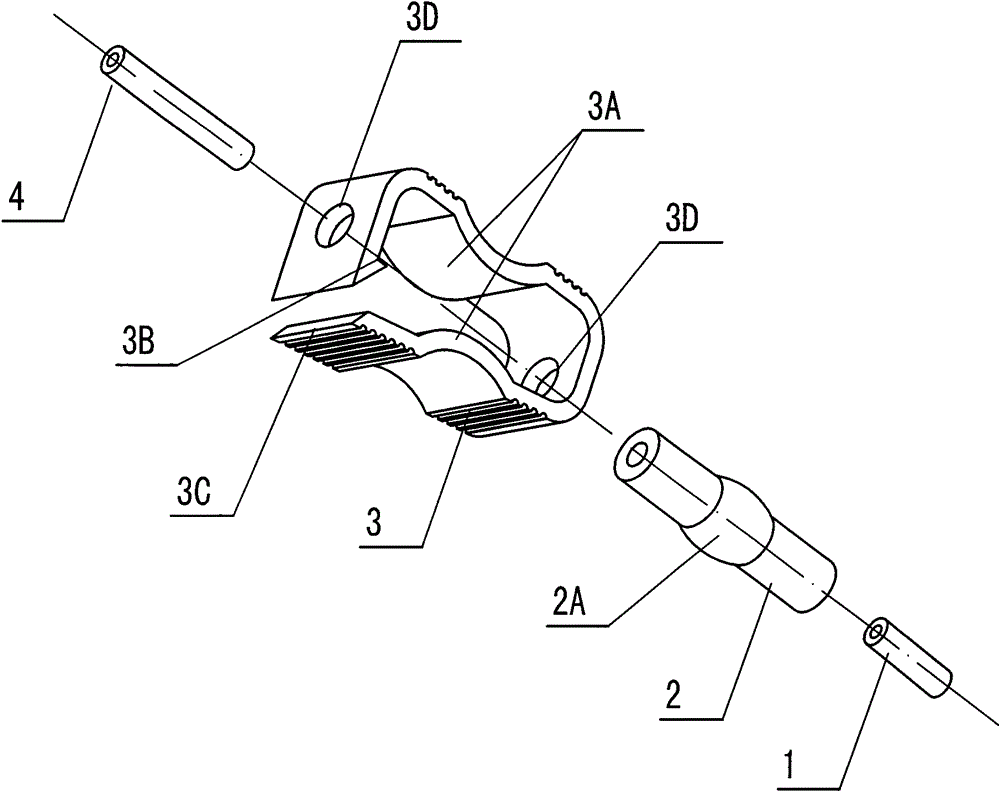

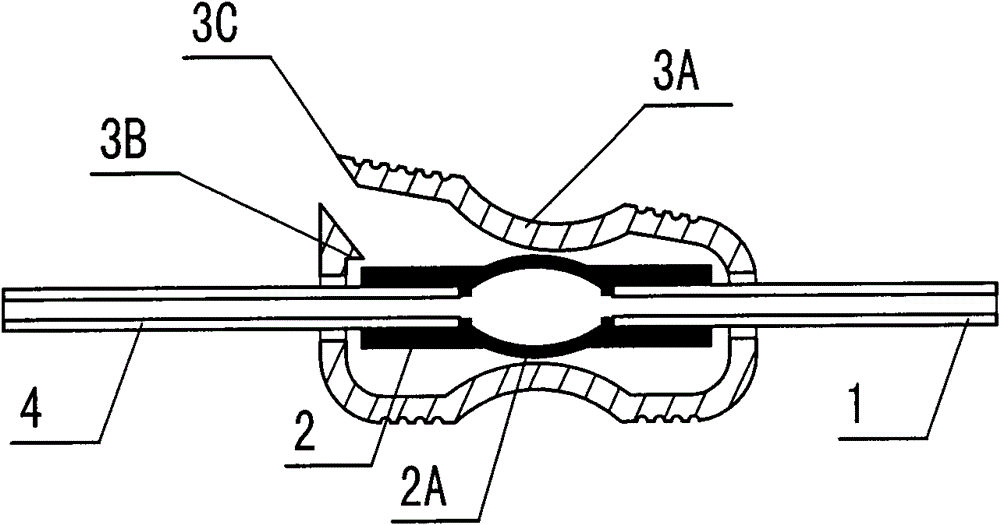

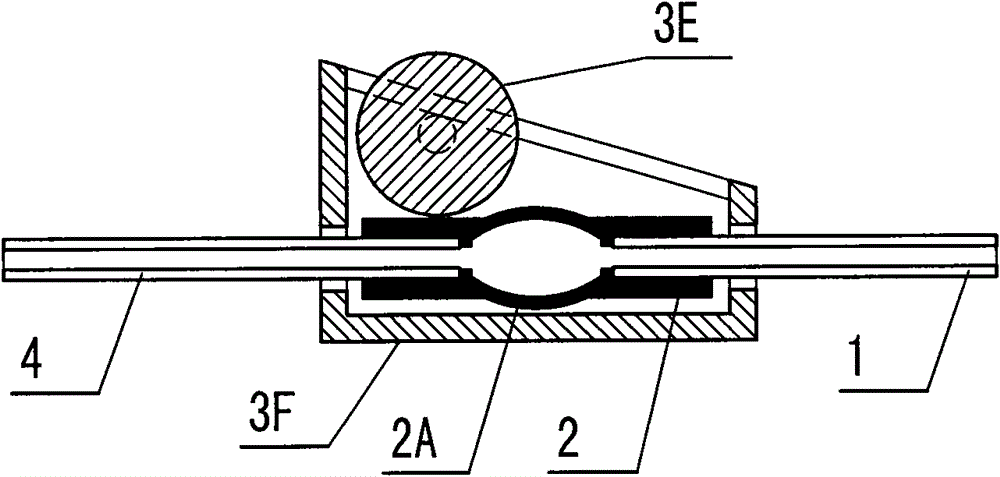

[0019] figure 1 It is a schematic diagram of the assembly structure of the present invention. It can be seen from this figure that a positive pressure capsule valve of the present invention is composed of a front catheter 1, a duct bag 2, a clip 3 and a rear catheter 4, wherein: the front catheter 1 and the rear catheter 4 are bonded On the outlets at both ends of the capsule 2, the capsule 2 is placed in the inner space enclosed by the clip 3; the capsule 2 is a tube section with a balloon 2A protruding outward in the middle, and the inner space of the balloon 2A is larger than the puncture for connection The volume of the needle or plug, the capsule 2 is made of medical elastic material; the clip 3 is a non-closed thin plate that is continuously bent in an approximate "8" shape, and there is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com