Gearbox with load distribution system

A technology of transmission and synchronizer, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., and can solve problems such as transmission jamming and difficulty in changing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

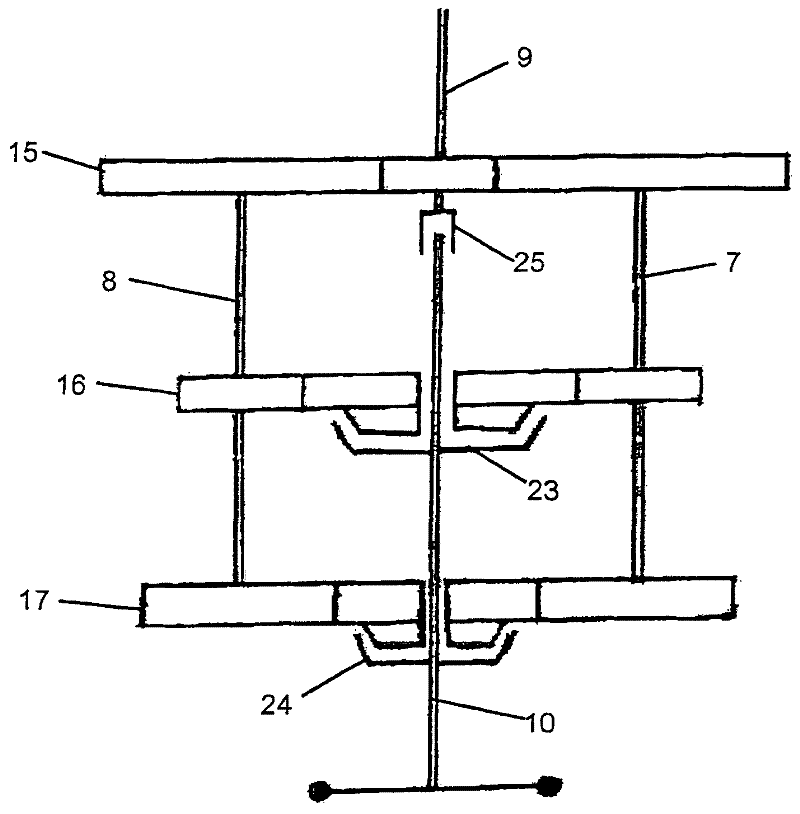

[0029] figure 1 The transmission shown in has been discussed in the context of the present invention.

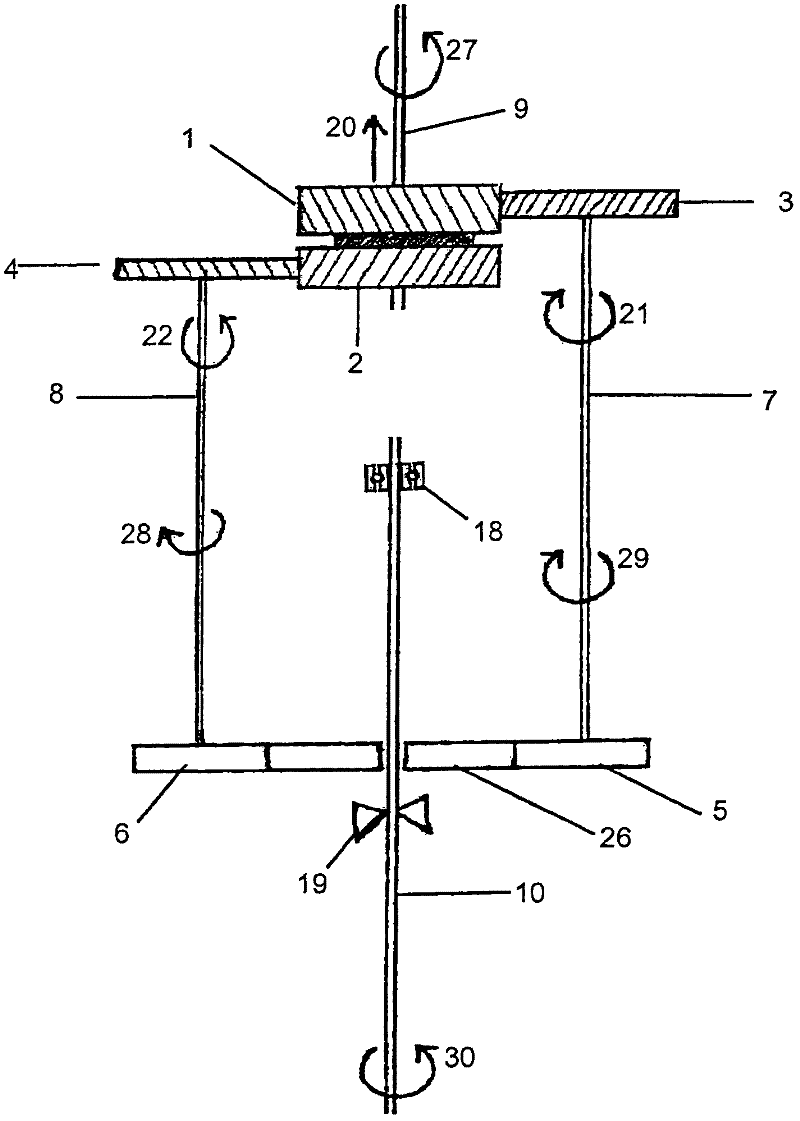

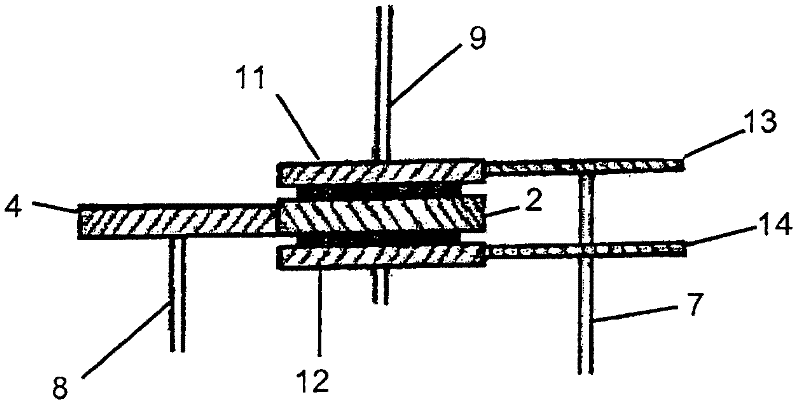

[0030] figure 2 The transmission shown in includes two helical gears 1, 2 in opposite directions, which are mounted on an input shaft 9 to be rotated by an input power source. These input gears 1, 2 are free to move axially, but whether axially or rotationally, the input gears 1, 2 are constrained to move in concert. Pairs of gears may be constrained by, for example, manufacturing them as one piece, or by connecting the two gears together with bolts, screws, welding or other connecting means. The set distance between the two input gears 1, 2 can be zero or greater than zero. Where this distance is non-zero, the gap between the gears may be maintained by rigid or compressible material inserted between the gears, for example mounted to the input shaft 9 .

[0031] The meshing of helical gears tends to induce opposing axial forces which will be approximately proportional t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com