Double clutch

A dual-clutch and friction clutch technology, applied in clutches, mechanical-driven clutches, fluid-driven clutches, etc., can solve the problem of high manufacturing cost of the clutch cover and achieve the effect of preventing dragging torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

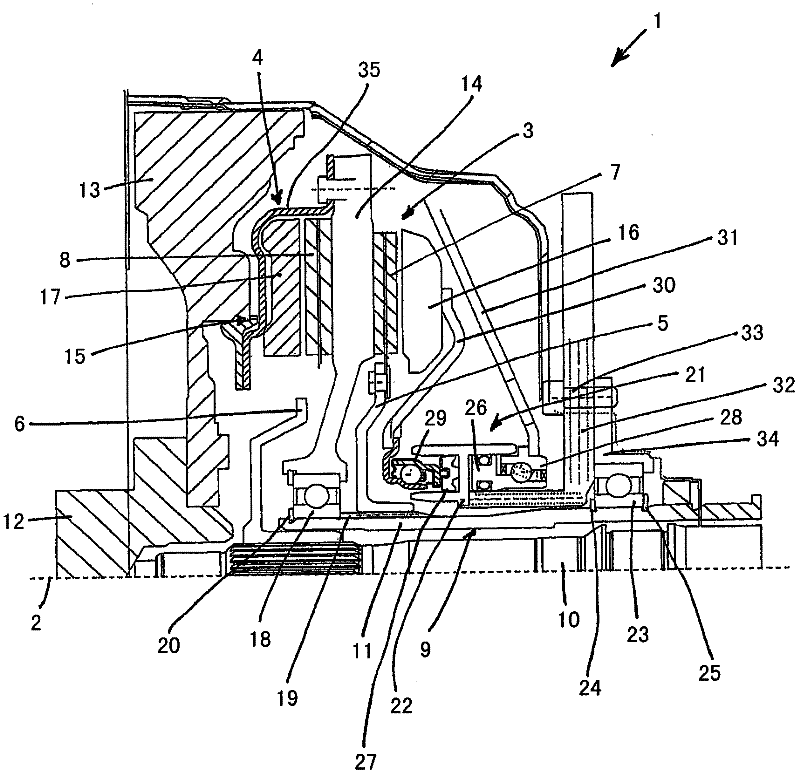

[0010] The invention is described in detail with reference to a single drawing. The figure shows a partial view of a double clutch 1 with two friction clutches 3, 4 above the axis of rotation 2. These friction clutches form a frictional engagement with the friction plates 7, 8 of the clutch disks 5, 6 according to their operation, wherein according to This friction fit transmits a torque introduced into the friction clutches 3 , 4 to the transmission input shafts 9 , 10 . The transmission input shaft 9 is formed as a hollow shaft 11 in which the transmission input shaft 10 is received concentrically.

[0011] The torque provided by the crankshaft 12 of the internal combustion engine (not shown) is transmitted to the dual clutch 1 via a flywheel 13 . In this case, in order to compensate the axial play, a tooth structure 15 is provided between the flywheel 13 and the counter pressure plate 14, which tooth structure is formed by the internal teeth of the flywheel 13 and the exte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com