Drive circuit capable of improving power factors of alternating current light emitting diode (AC LED) lamp

A technology for driving circuits and LED light strings, which is applied in the layout of electric light circuits, conversion devices for output power, and high-efficiency power electronic conversion, etc. The effect of improving reliability and high power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

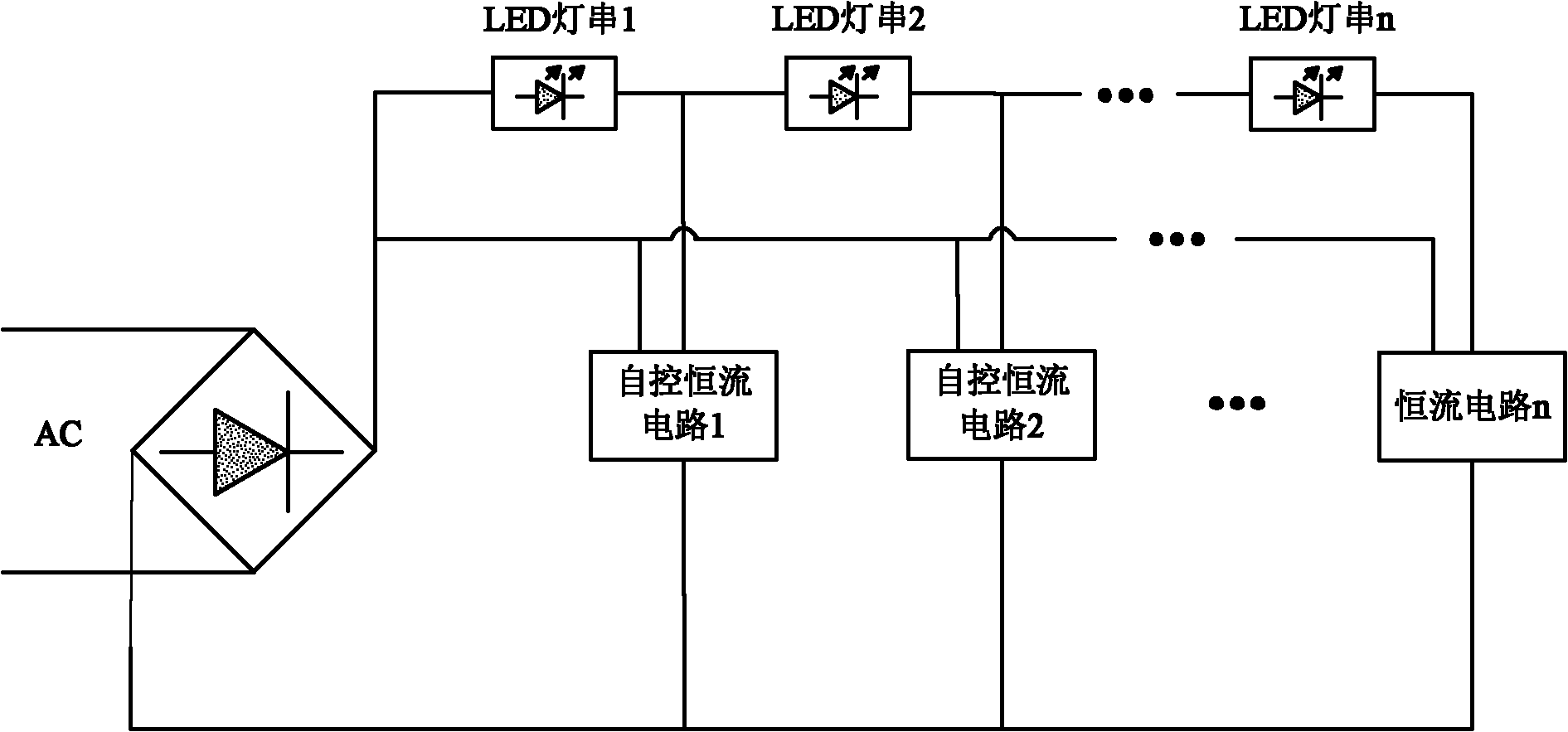

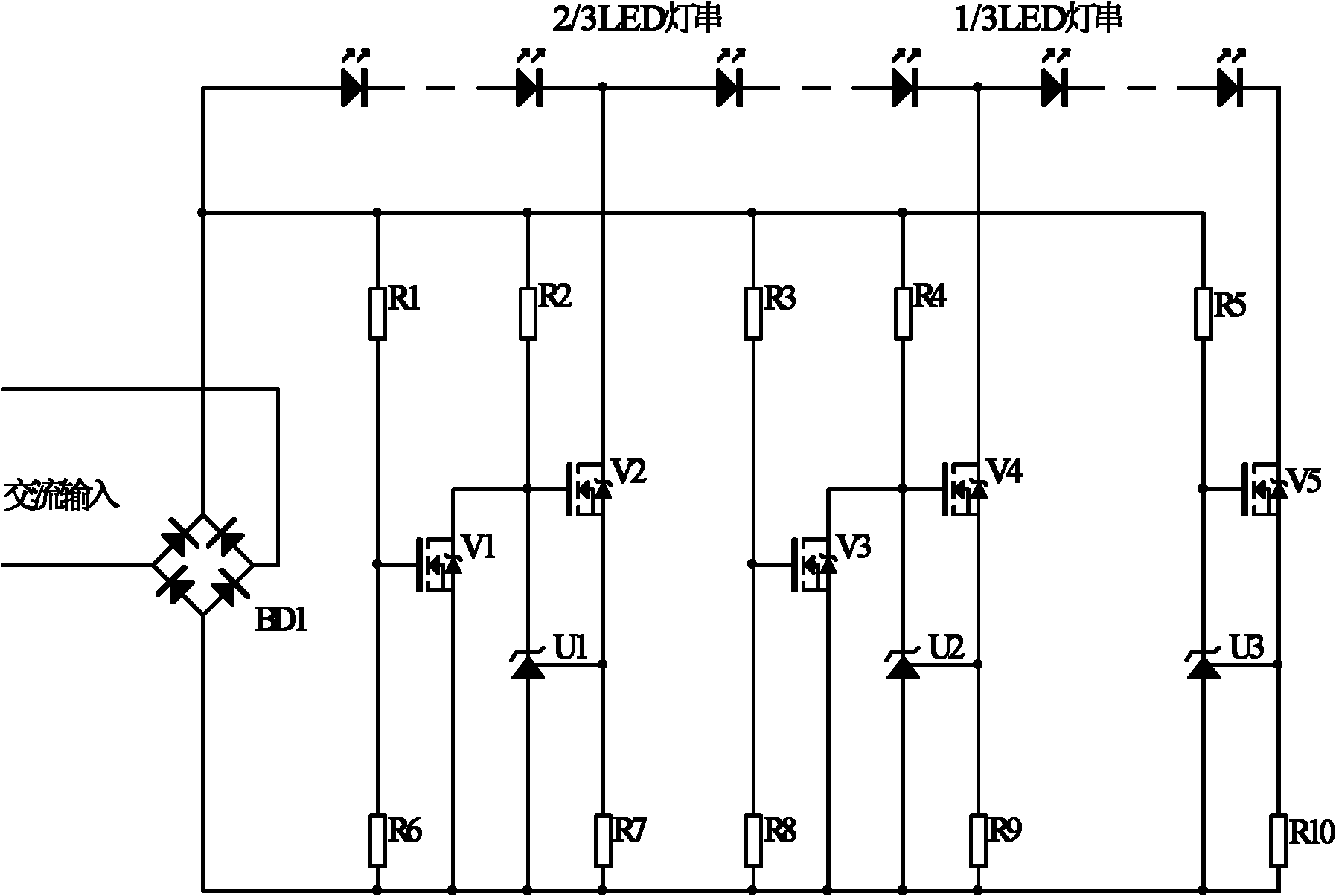

[0023] Such as figure 2 As shown, a drive circuit that can improve the power factor of AC LED lamps is composed of a rectifier bridge BD1, three series-connected LED lamp strings (20 per string) and three corresponding self-controlled constant current circuits.

[0024] The three self-controlled constant current circuits are respectively connected to 1 / 3, 2 / 3 of the series LED light string and the negative end of the light string. The rectifier bridge BD1 rectifies the 220V / 50Hz alternating current into a 100Hz steamed bun wave. Resistors R1, R2, R6, R7, MOS tubes V1, V2 and voltage reference U1 form the first self-control constant current circuit; resistors R3, R4, R8, R9, MOS tubes V3, V4 and voltage reference U2 form the second self-control circuit Constant current circuit, resistors R5, R10, MOS transistor V5 and voltage reference U3 constitute the last constant current circuit.

[0025] When the input voltage is below 1 / 3 of the rated range (<73.3V), V1 is turned off a...

Embodiment 2

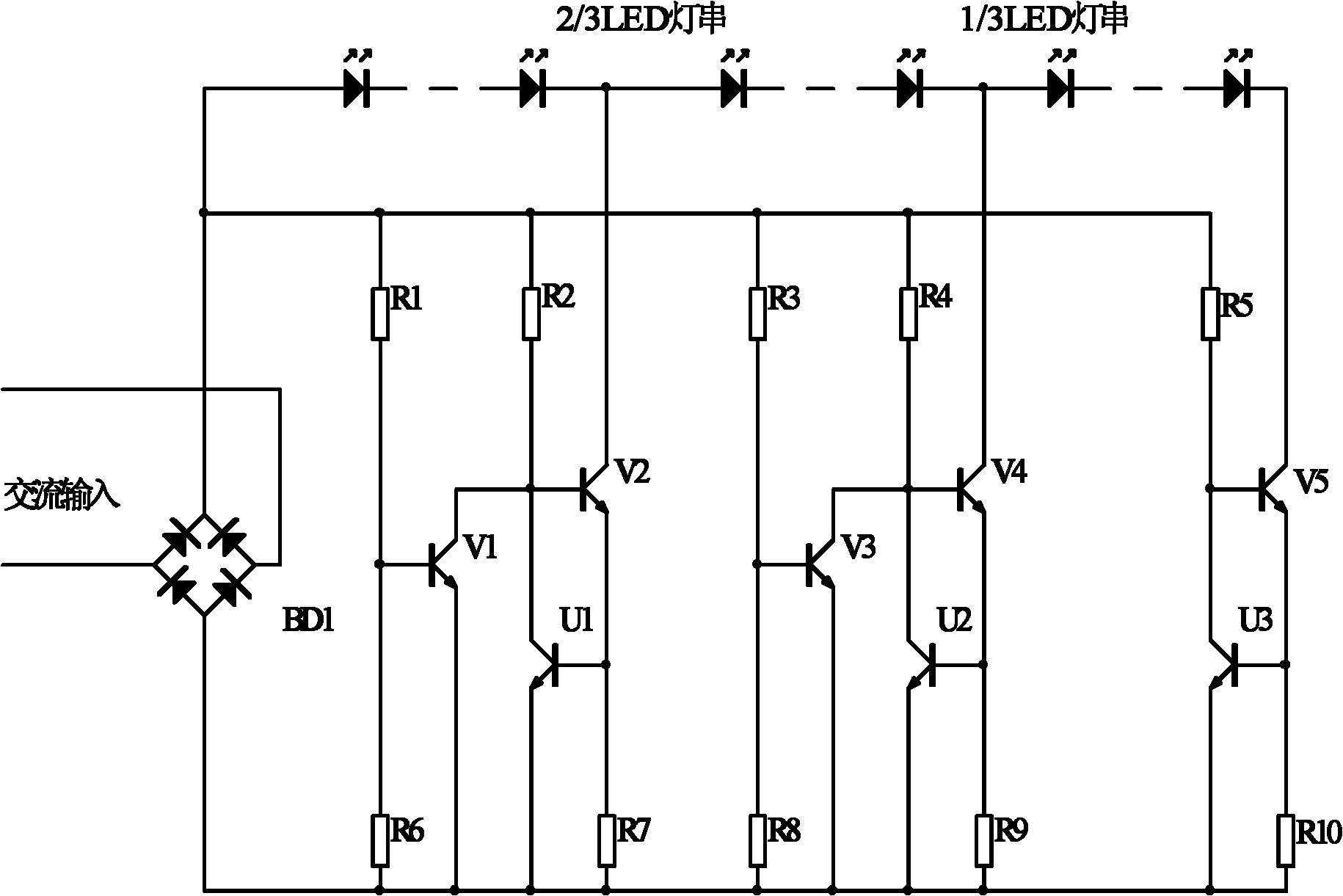

[0036] Such as image 3 As shown, another drive circuit that can improve the power factor of AC LED lamps differs from the first embodiment in that the MOS transistors V1, V2, V3, V4, V5 and voltage references U1, U2, U3 can be replaced by triodes. The working principle of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

[0037] The present invention can correct the waveform of the input current by controlling the conduction quantity of the LED lamp strings and limiting the current flowing through the LED lamp strings in sections, so as to achieve the purpose of power factor correction. Using the power factor correction drive circuit of the present invention, the input voltage and current waveforms are as follows Figure 4 As shown, the power factor is greatly improved to around 0.97-0.99.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com