Direct-drive high-performance permanent magnet brushless motor for electric vehicle

A permanent magnet brushless motor and electric vehicle technology, applied in electric vehicles, motors, electric components, etc., can solve the problems of low power density of brushless permanent magnet motors, low starting torque of AC induction motors, and low reliability, and achieve Solve heat dissipation problems, reduce car noise, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] This specific embodiment is only an explanation of the present invention, and it is not a limitation of the present invention. Those skilled in the art can make modifications to this embodiment without creative contribution as required after reading this specification, but as long as they are within the rights of the present invention All claims are protected by patent law.

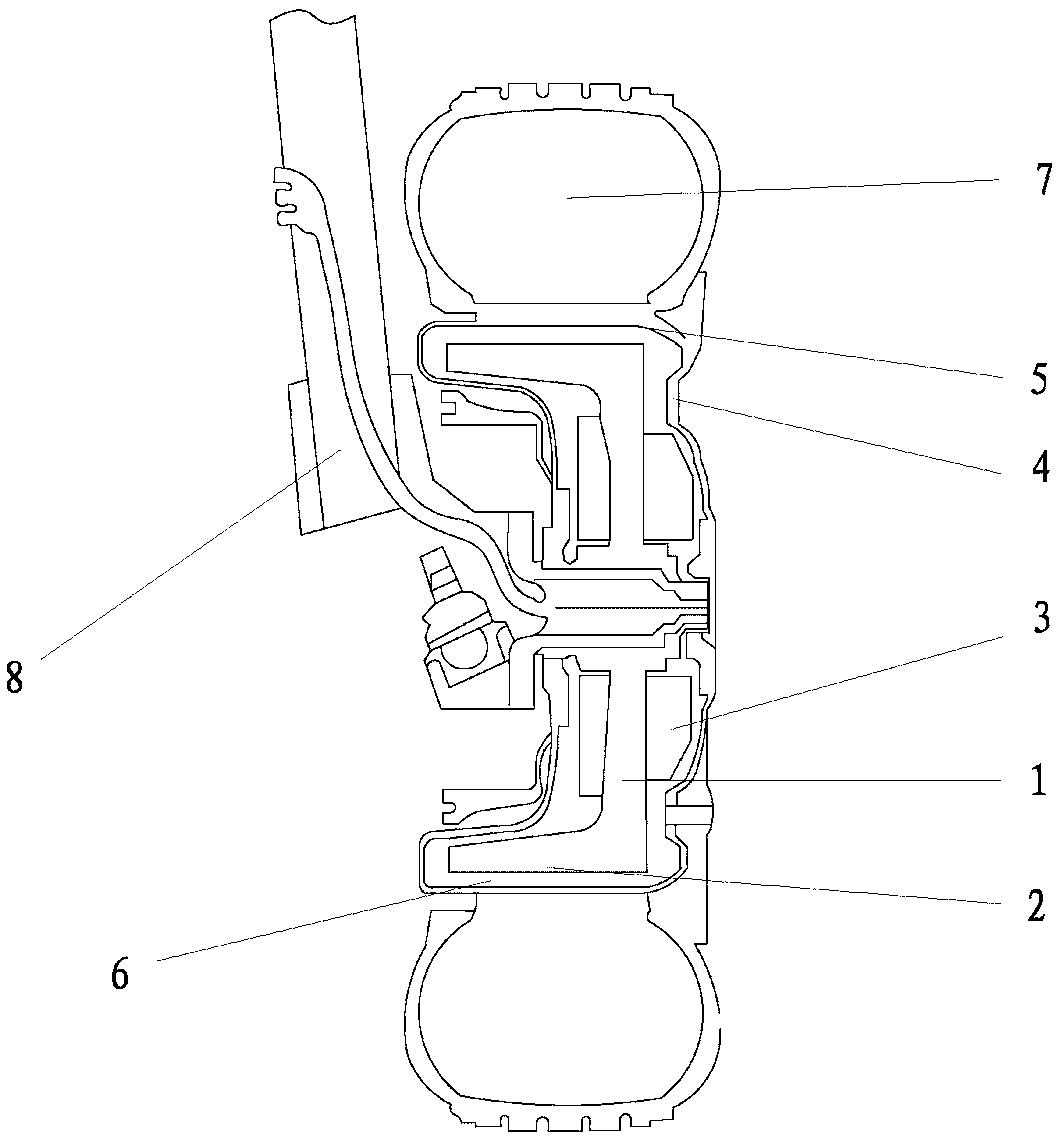

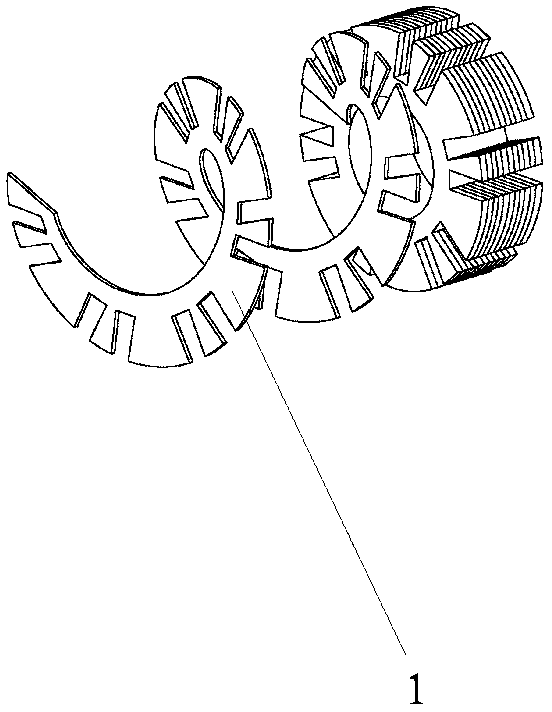

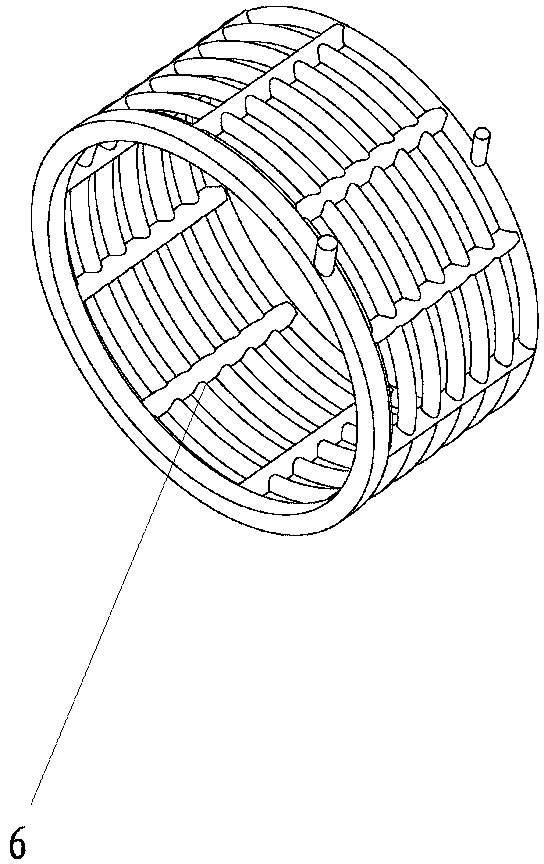

[0035] Such as Figure 1~3 As shown, the direct-drive high-performance permanent magnet brushless motor for electric vehicles includes an inner stator part and an outer rotor part, the outer rotor part is used to connect the tire 7, the inner stator part is connected with the automobile suspension 8, and the inner stator part includes Motor stator 1, motor winding 2 and motor controller 3, the outer rotor part includes motor rotor 4 and permanent magnet 5, the motor stator 1 is a coiled structure of helical strip iron sheets, and the coiled structure is wide teeth The structure of narrow teeth alt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com