Sensor capable of continuously measuring ablation

A sensor and sensitive technology, applied in the field of aerospace sensors, can solve the problems of wasting the internal space of the aircraft, occupying the payload of the aircraft, and long production cycle, and achieve the effect of improving measurement accuracy, shortening production cycle, and long production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

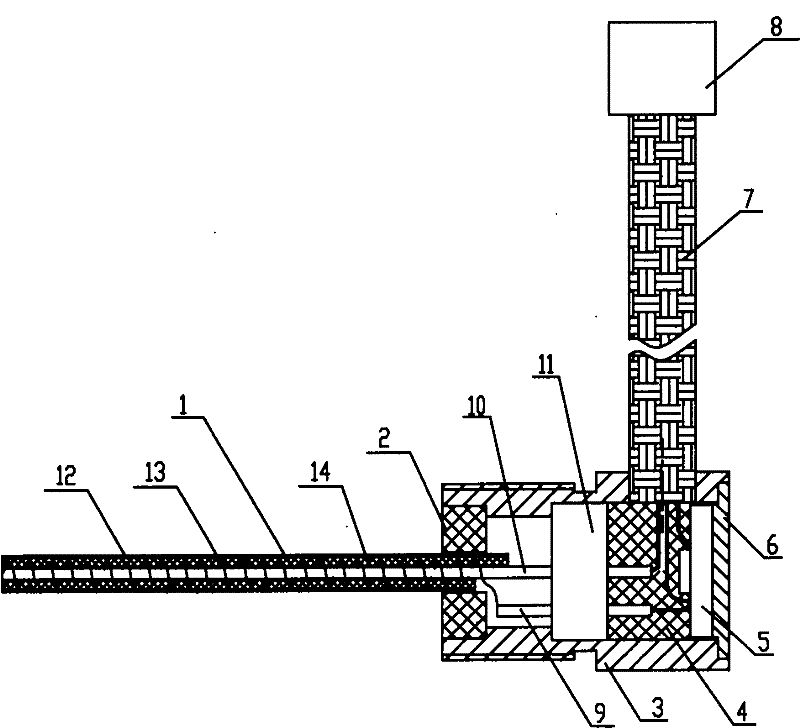

[0035] Such as figure 2 Shown is a schematic diagram of the structure of the sensor of the present invention. It can be seen from the figure that the sensor includes a sensitive component 1, a blocking block 2, a housing 3, a printed board assembly 5, a back cover 6, a cable 7 and a connector 8.

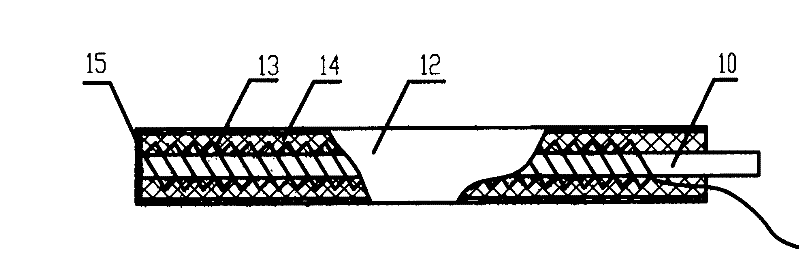

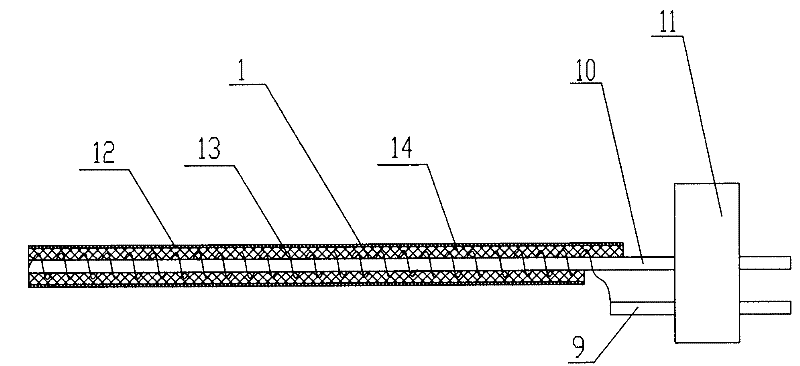

[0036] Such as image 3 Shown is a schematic structural diagram of the sensitive component 1 in the sensor of the present invention, the sensitive component 1 includes a capillary 12, an insulating seat 11, a core wire 10, a lead wire 9, a winding wire 13 and a filling material 14, and a layer of filling material is pre-coated on the core wire 10 14. Insulate the outer surface of the core wire 10, then wrap the winding wire 13 evenly on the core wire 10, and one end of the winding wire 13 is welded on the core wire 10, and the other end is wound on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com