Intelligent dragline and wind power generation hightower adopting same

An intelligent cable and intelligent technology, applied in wind turbine components, wind power generation, wind turbines, etc., can solve problems such as reducing the reliability of wind power tower systems, affecting the normal operation of wind turbines, and damage to fixed connection structures, etc., to achieve Increase safety and stability, low cost, and overcome the effect of poor anti-vibration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the embodiments shown in the accompanying drawings.

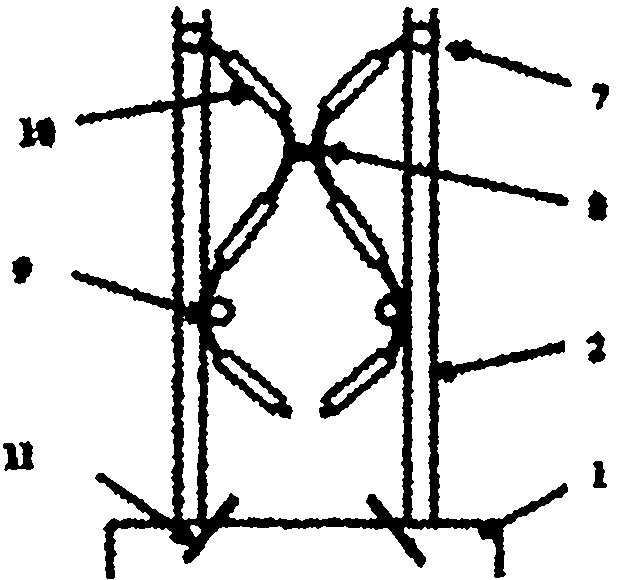

[0017] figure 1 The structure of the present invention is shown, consisting of figure 1 It can be seen that the vibration control system of the wind power tower of the present invention includes a foundation 1, a tower 2, a nacelle and an internal structure 3, a hub 4, a blade 5, and a cable system 6. The cable system 6 is installed in the tower 2, and its structure like figure 2 As shown, including the top anchor ring 7, the anchor ring 8 in the tower, the tower wall pulley 9, the SMA bar 10, and the prestressed cable 11, the positional relationship of each part is: the four top anchor rings 7 are arranged on the top of the tower 2, and the middle The anchor rings 8 in the tower are installed at equal intervals, and the tower wall pulleys 9 are installed on the wall of the tower 2 at equal intervals, wherein the number of the anchor rings 8 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com