Oxygen sensor

An oxygen sensor and sensor technology, applied in the field of oxygen sensors, can solve problems such as affecting the sealing and waterproof effect of the oxygen sensor, the oxygen sensor cannot work normally, and reducing the service life of the oxygen sensor, and achieves good waterproof and heat dissipation effects, simple structure, and manufacturing. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with preferred specific embodiments.

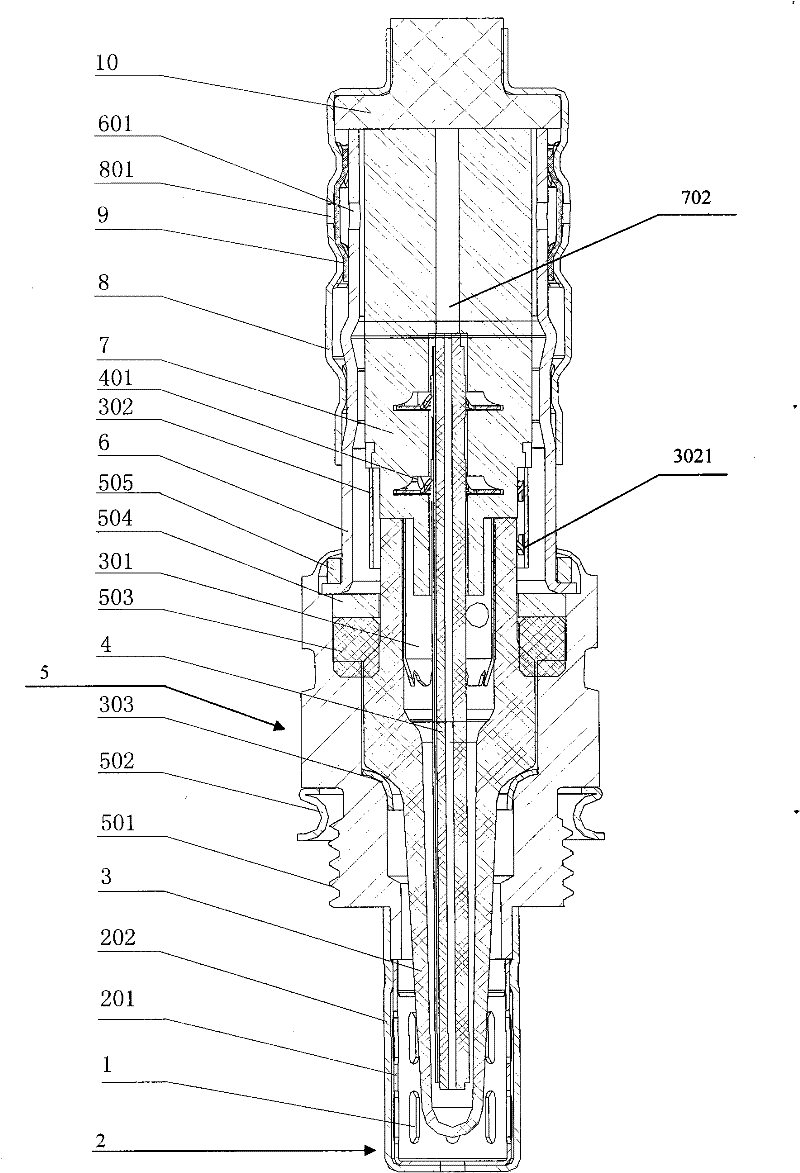

[0037] Such as figure 1 As shown, the oxygen sensor of the present invention includes a sensing element 3, a sensor base 5, a housing 6, and a ceramic body 7; one end of the housing 6 is connected to the sensor base 5, and the other end is connected to the sealed terminal 10, which Ceramic body 7 is built-in. The sensing element 3 is located in the cavity formed by the sensor base 5 and the housing 6, the opening end presses the ceramic body 7 tightly, and the other end is closed, the sensor base 5 and the housing 6 are connected by pressure riveting, the sensor base A third gasket 505 is provided between 5 and the housing 6 to ensure a stable connection between the sensor base and the housing.

[0038] The closed end of the sensor element 3 is provided with a protective cover 2 outside, including an inner protective cover 201 and an outer protective cover 202. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com