Method and device for solidifying water-filling cracking surrounding rocks of tunnel by adopting high-pressure air water-dispelling grouting

A technology of crushing surrounding rock and high-pressure air, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve the problems of complex process, high cost, and poor effect, and achieve the effects of improving process, simplifying construction, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

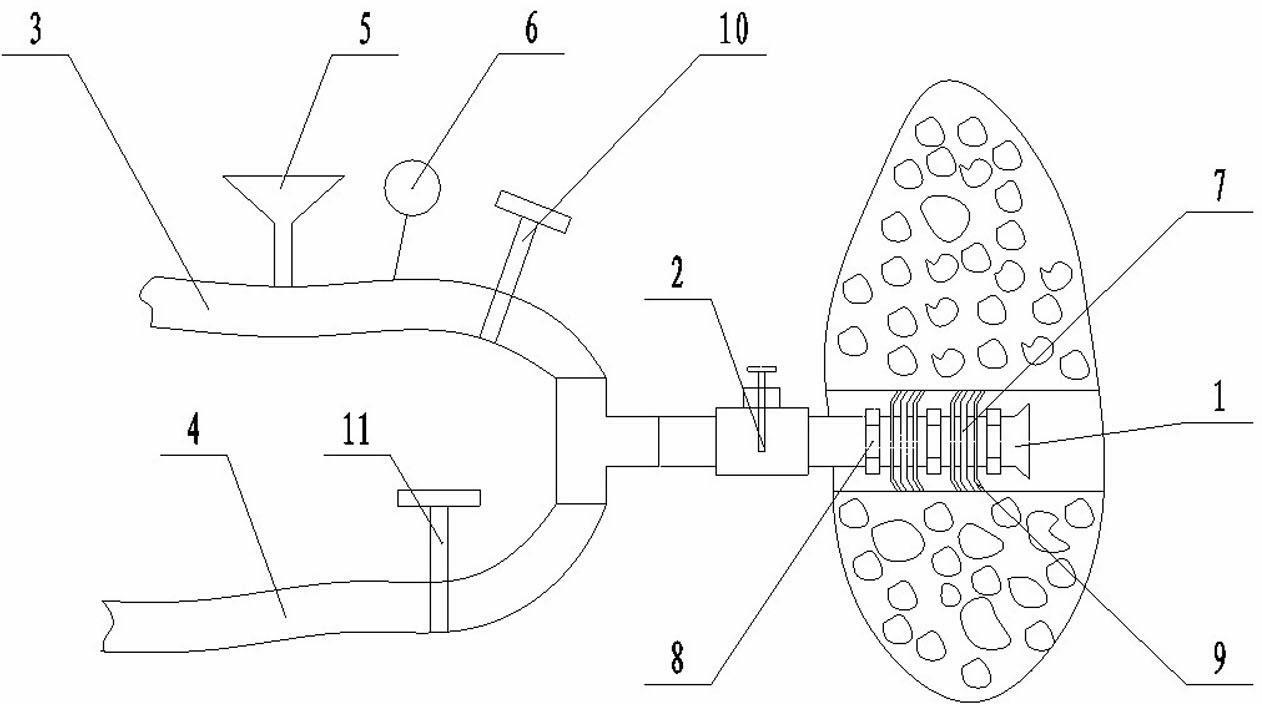

[0014] The water-filled broken surrounding rock high-pressure air flooding grouting reinforcement method adopts the following steps: a. After finding out the range of water-filled broken surrounding rock and the water filling situation, drill horizontal geological holes, and then insert the pressure-resistant pipe fitting 1 and seal it Surrounding; b. Close the excavation working face to form a slurry wall; c. Pass high-pressure air into the pressure-resistant pipe fitting 1 to replace and discharge the water filling in the gap of the broken surrounding rock; d. After the air pressure is maintained in balance, the pressure-resistant pipe fitting 1 Cement grout fills the broken surrounding rock in which water is replaced by air in the void. The quick-setting slurry is fed into the pressure-resistant pipe fitting 1 while the high-pressure air is passed through; the light-weight and water-swellable sealing material is fed into the pressure-resistant pipe fitting 1 while the high-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com