Mega column in shape of double Chinese characters ya and manufacturing method thereof

A manufacturing method and technology for giant columns, which are applied to columns, piers, pillars, etc., can solve the problems of difficult control of geometric dimensions, long welding time, comprehensive deformation of components, etc., and achieve ingenious structural design, improved production efficiency, and strong load-bearing effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

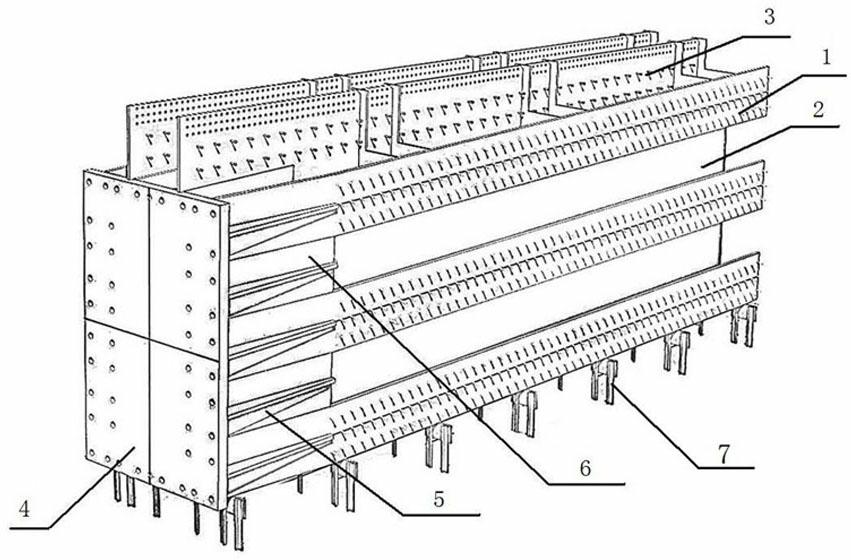

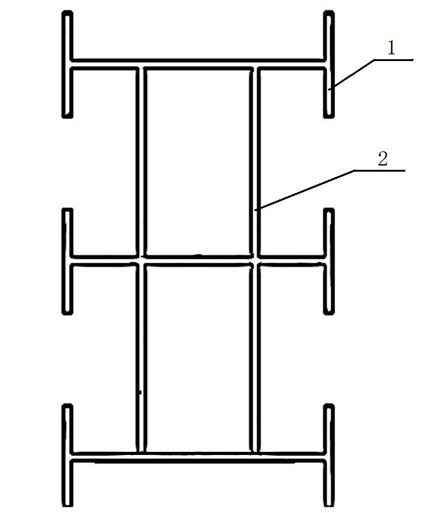

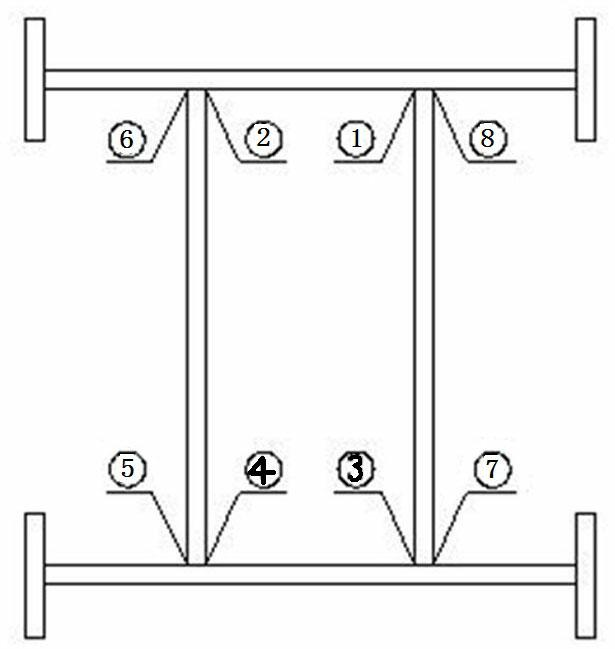

[0038] Such as figure 1 A double-sub-shaped giant column is shown, which includes: three H-shaped members 1, two layers of partitions 2, two layers of connecting plates 3, one column bottom plate 4, twelve transverse stiffened plates 5, four horizontal stiffened plates Rib 6 and some pegs. In this embodiment, three H-shaped components are stacked together, and the partition is located between two adjacent H-shaped components; the two-layer connecting plate is located on the side of the H-shaped component; The stiffened plate 6 is located between two adjacent H-shaped members, and the transverse stiffened plate 5 is vertically fixed to the column bottom plate 4 and at the same time perpendicular to the side of the H-shaped member 1; one end of the transverse stiffened plate 5 is fixed on the column bottom plate 4 , one end is fixed on the surface of the H-shaped member or the horizontal stiffened plate 6 .

[0039] This embodiment also discloses a method for making the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com