Device for bonding, curing, and pressing side window glass of metrovehicle

A pressing device, bonding and curing technology, applied in the direction of adhesive, bonding method, etc., can solve the problems affecting the bonding force and air tightness, the plane distortion of the window, the position distribution error, etc., to ensure the bonding strength, and the The body is flush and the effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings.

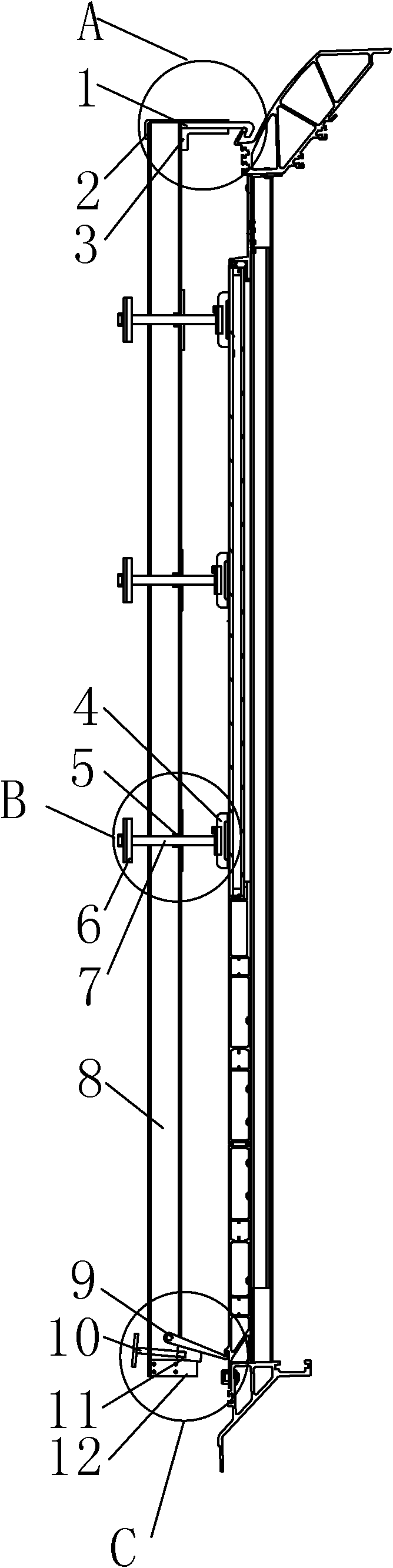

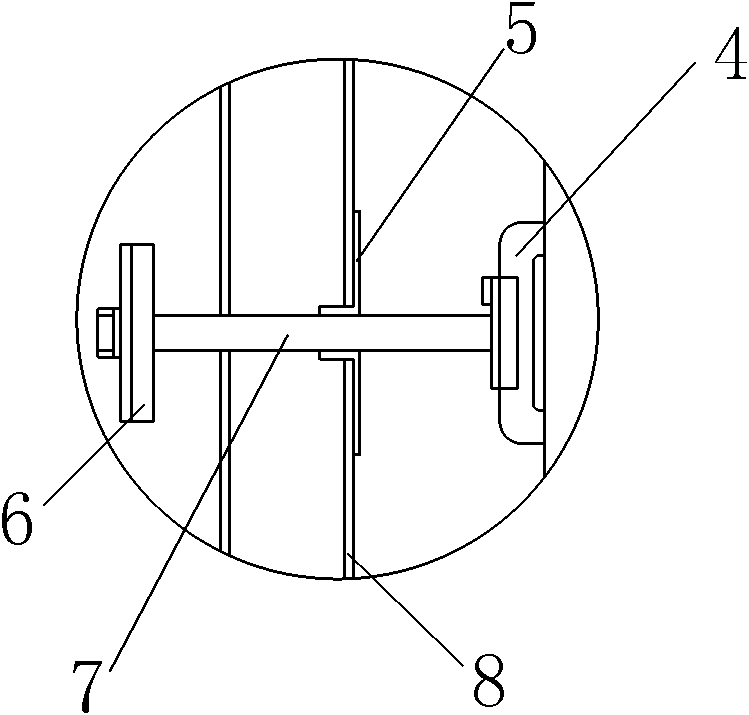

[0015] Such as figure 1 As shown, a kind of subway car side window glass adhesive curing pressing device of the present invention comprises connecting rod 8 and suspension device, pressing device and fastening device, and described suspension device is arranged on the upper end of connecting rod 8; The device is arranged on the connecting rod 8 at the same height as the side window glass; the fastening device is arranged on the lower end of the connecting rod 8 .

[0016] The connecting rod 8 is a hollow square tube with the same height as the side of the subway car. It is made of aluminum alloy and has a light weight and high rigidity. The connecting rod 8 is parallel to the side window glass when in use.

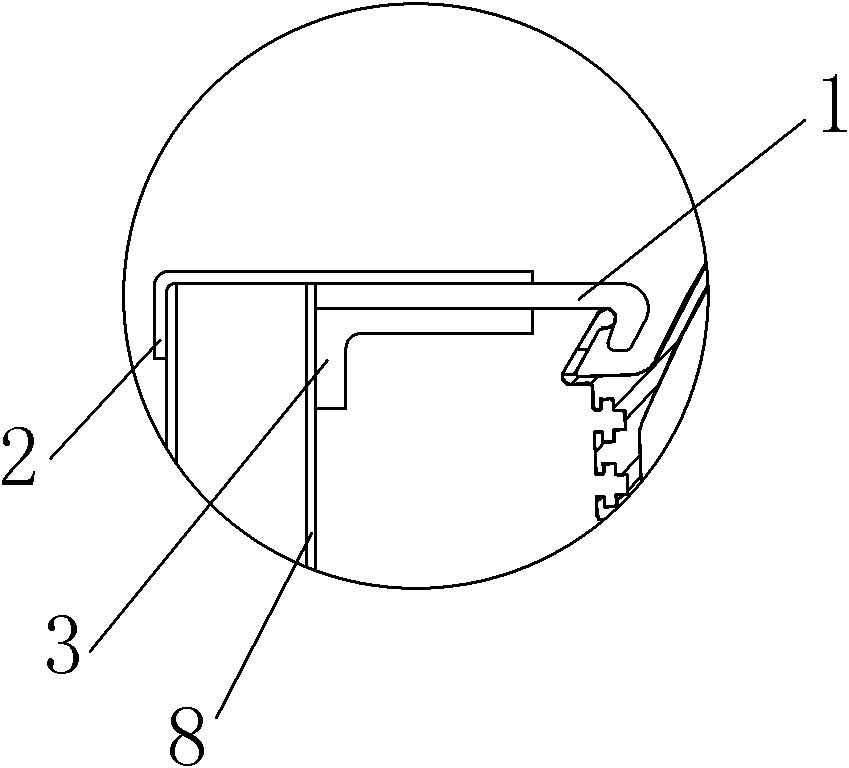

[0017] Such as figure 2 As shown, the suspension device includes an upper hook 1, the head of which is a crotch adapted to the shape of the upper edge of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com