Cost based method for optimizing external PHEV (Plug-in Hybrid Electric Vehicle) power assembly and application thereof

A hybrid electric vehicle and powertrain technology, which is applied in the field of optimal design of the PHEV powertrain system of an externally rechargeable hybrid electric vehicle, can solve the problems of limited battery capacity and the impossibility of completely replacing petroleum-driven vehicles with electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

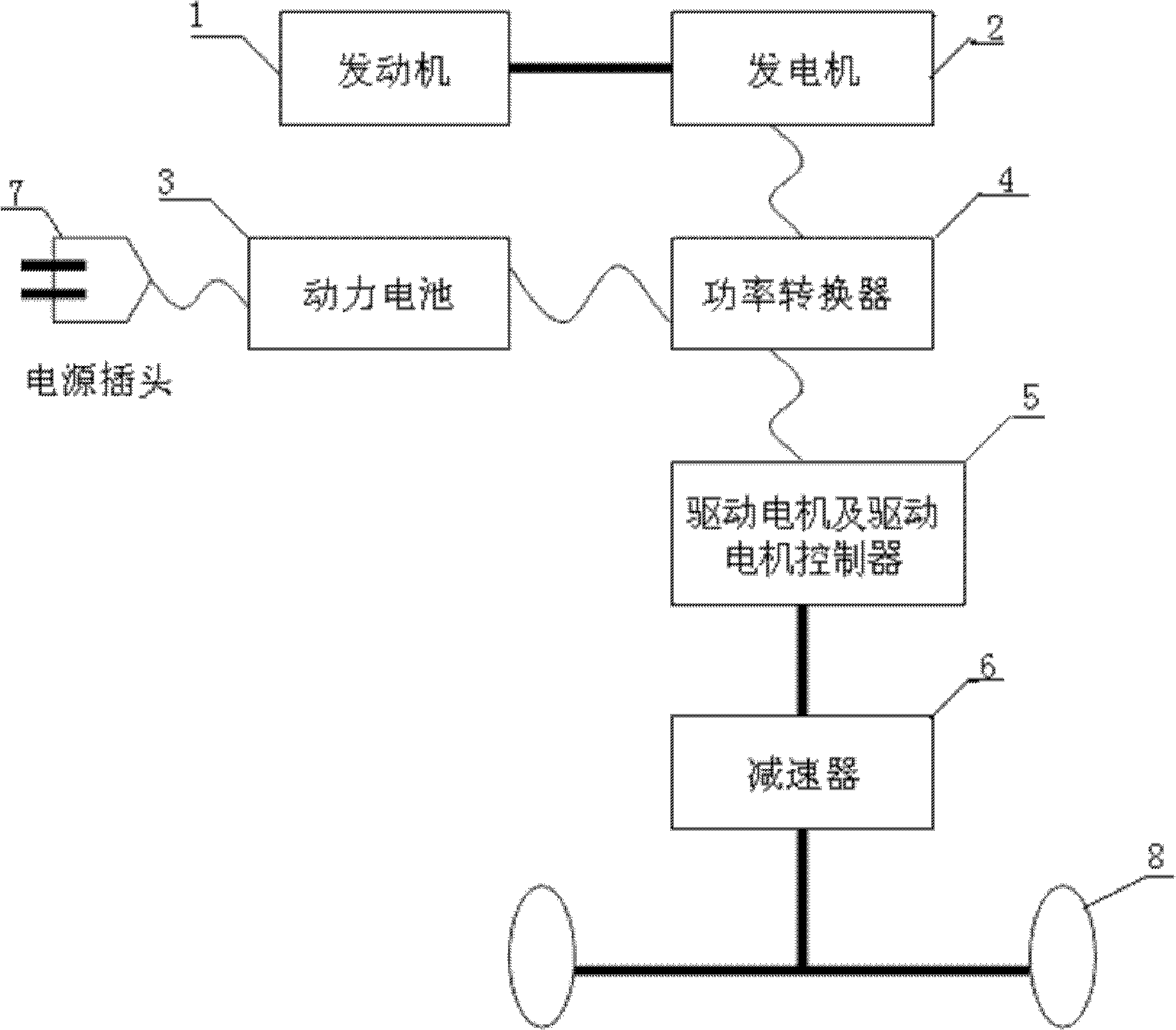

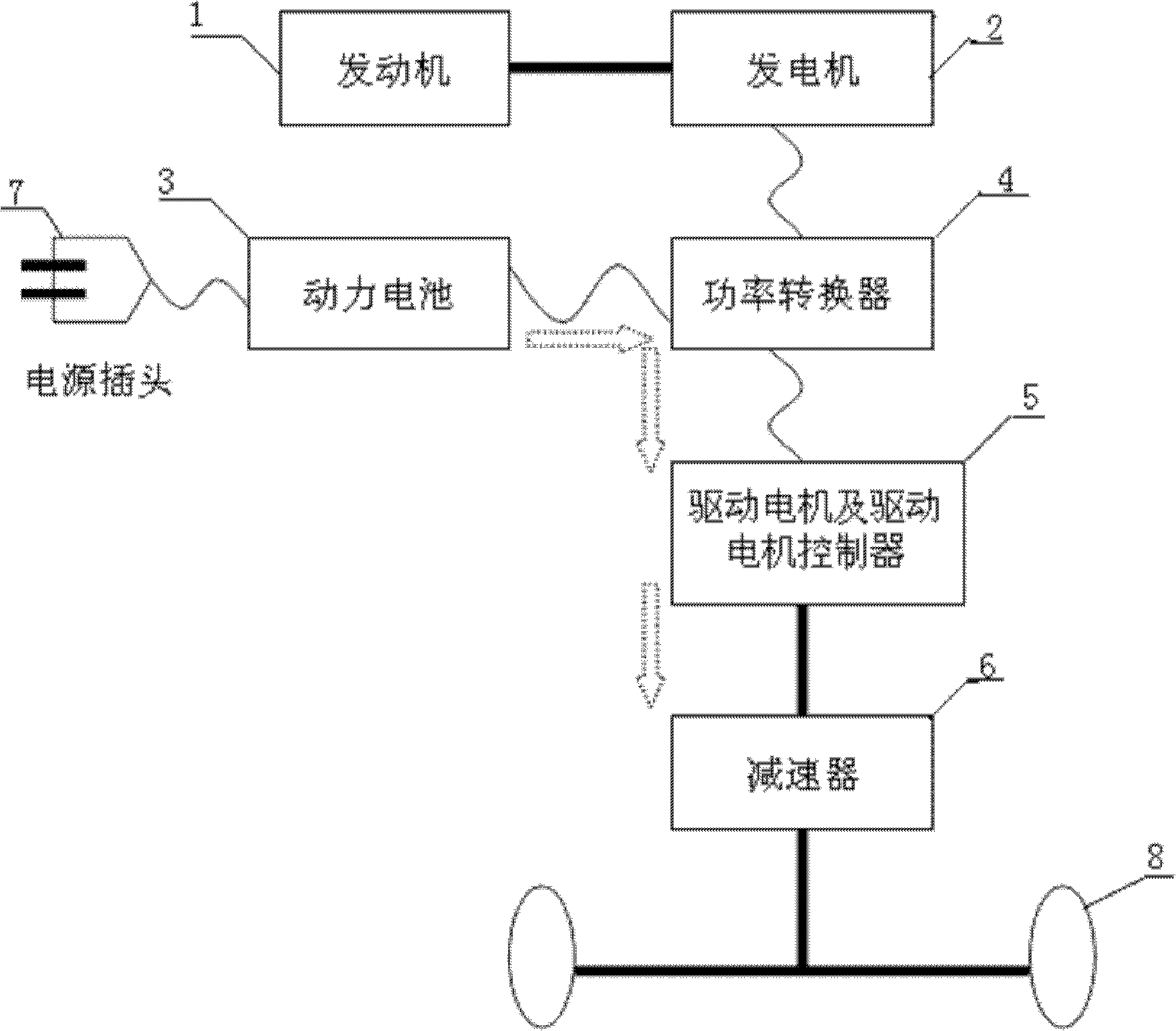

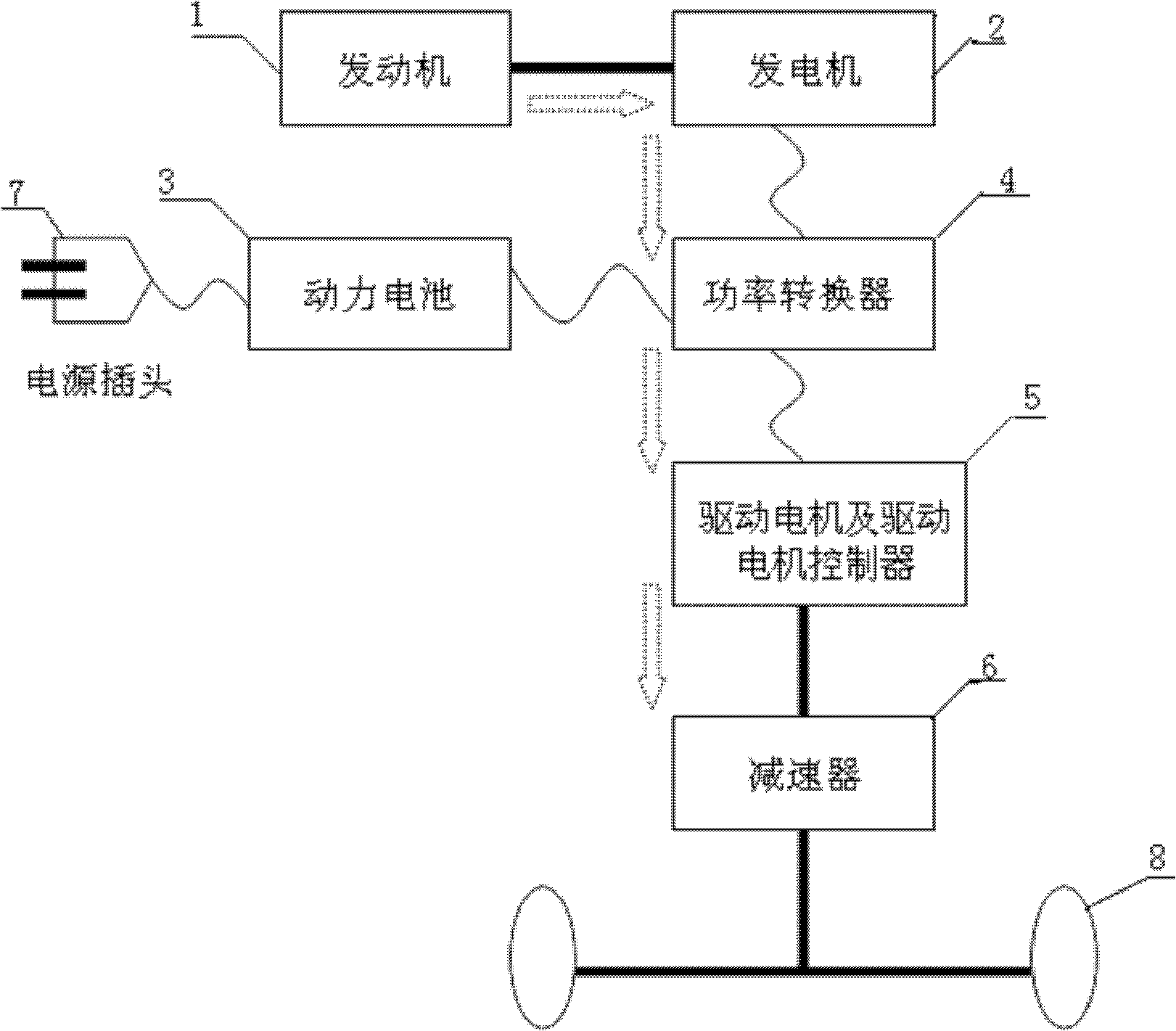

[0074] Due to the different components, layout and control strategies of hybrid electric vehicles, various structural types are formed, and the manufacturing and use costs of different structural schemes are also different. Therefore, in order to compare with traditional automobiles and ordinary hybrid electric vehicles , the cost-based optimal design method of PHEV powertrain system has practical significance, and provides reasonable quantitative indicators for PHEV manufacturing and use costs.

[0075] In this embodiment, according to the layout structure of the PHEV powertrain, the variables to be optimized in the optimal design of the PHEV powertrain system are determined, the PHEV cost objective function equation and constraint conditions are established, and the optimal design of the PHEV powertrain system is transformed into an optimization problem, and then Using the optimization method, the variables to be optimized for the powertrain system that can meet the PHEV cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com