Method and device for centering initial welding positions of flat narrow welding lines and tracking welding lines

A welding position and flat plate technology, applied in position/direction control, welding equipment, arc welding equipment, etc., can solve problems such as no consideration, and achieve the effect of low cost of use, strong usability, simple and reliable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

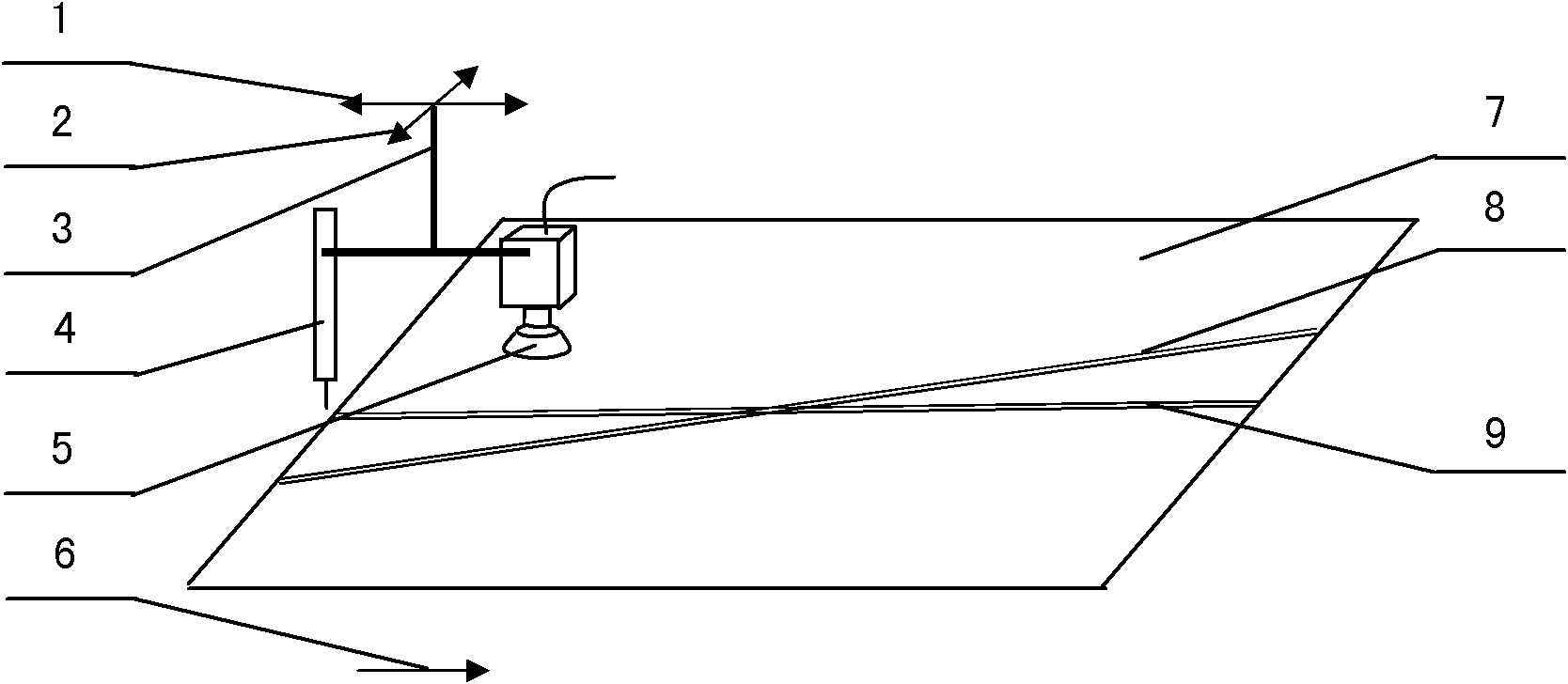

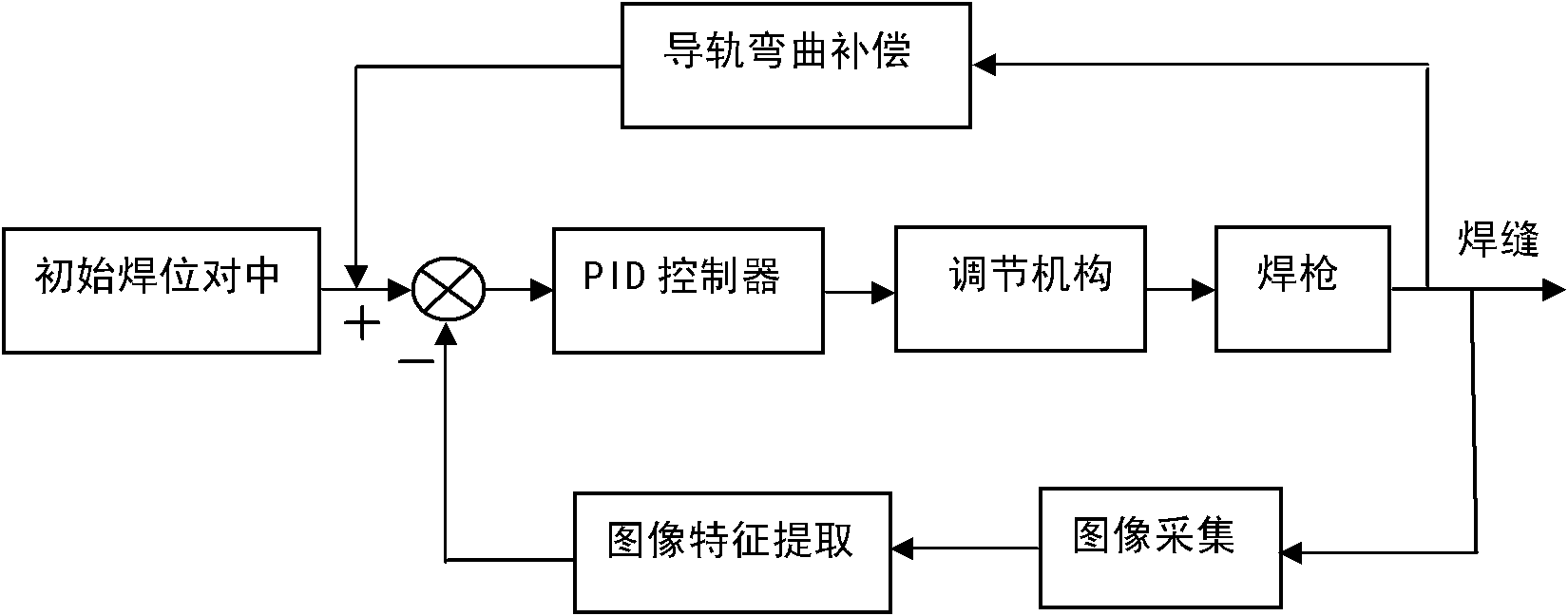

[0016] see figure 1 It is the schematic diagram of the initial welding position centering of the flat narrow weld seam, figure 1 It includes a traveling mechanism 1, an adjusting mechanism 2, a connecting rod 3, a welding torch 4, a camera 5 and a PID controller, wherein the traveling mechanism 1 and the adjusting mechanism 2 are symmetrically connected to the center, and one end of the vertical part of the connecting rod 3 is located in the traveling mechanism 1, perpendicular to each other and fixedly connected; the welding torch 4 and the camera 5 are respectively fixed at both ends of the horizontal part of the connecting rod 3, and the connecting rod 3 is fixedly connected to the welding torch 4 and the camera 5 as a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com