Foam controlling and flotation method for zinc oxide ore

A zinc oxide ore and zinc oxide technology, applied in flotation, solid separation, etc., can solve the problems of difficult foam treatment control, large foam volume, poor fluidity, etc., and achieve the effect of improving the level of industrial flotation and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

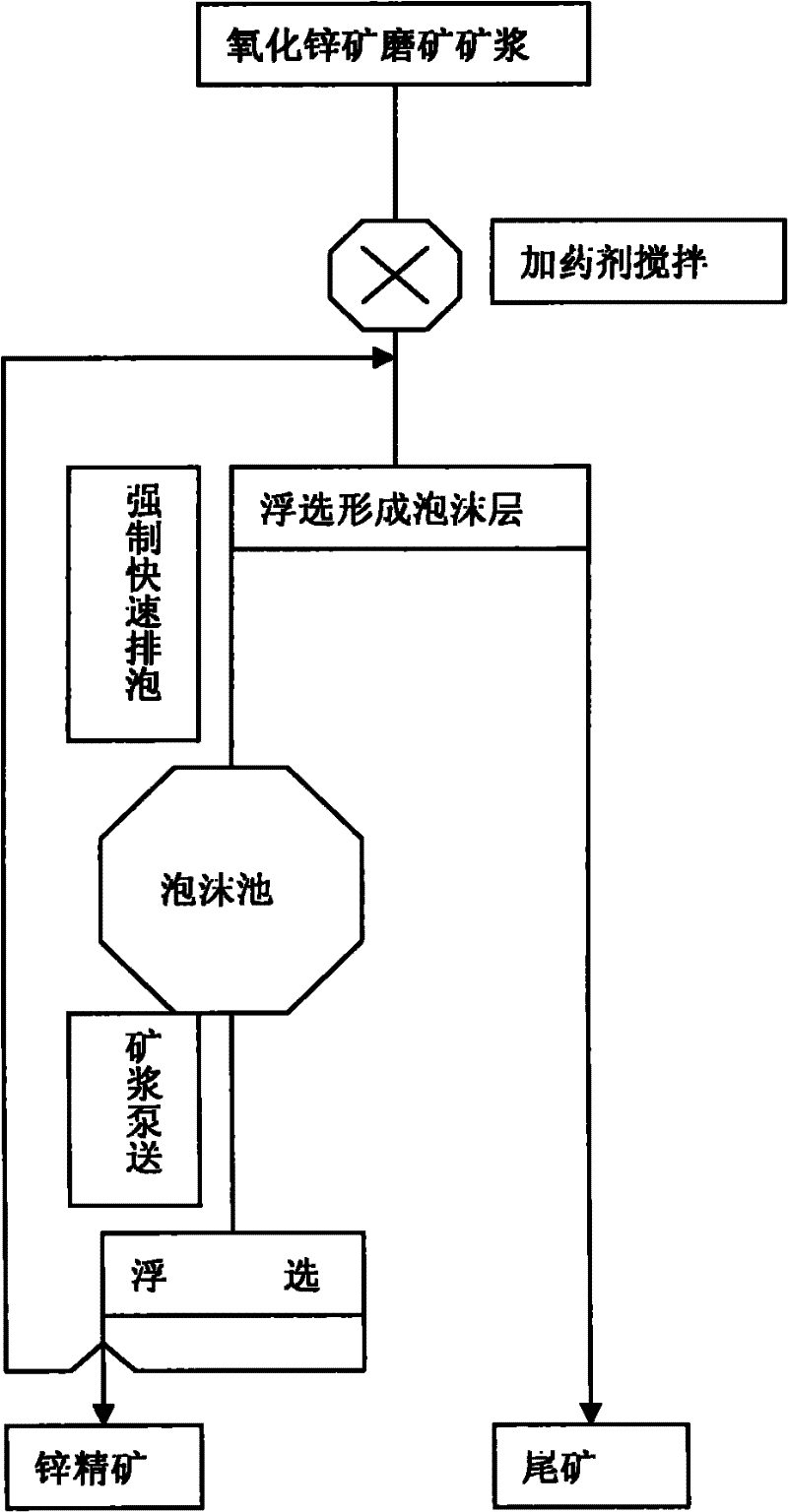

[0019] Embodiment 1: raw ore grade: 5% to 8% zinc, processing capacity: 40 to 60t / h zinc oxide ore;

[0020] Introduce the zinc oxide ore non-delimed slurry with a mass percentage concentration of 30% to 35% into the mixing tank, add 8 to 12kg / t of sodium sulfide to adjust the slurry, and then add 400 to 800g / t of 12 amine collectors and zinc oxide mineral response. The reacted ore pulp is introduced into the flotation machine, and mixed alcohol foaming agent 10-40g / t is added for flotation. Hydrophobic zinc oxide minerals are attached to the air bubbles and float on the liquid surface of the ore pulp to form a large amount of foam layer with poor fluidity. ;

[0021] The foam layer is quickly pushed into the foam tank of the flotation machine by the spiral bubble-discharging and quick-scraping mechanism, and then high-pressure water and high-pressure air are used to form jets to impact the foam, and the foam is transported to the foam pool;

[0022] Dissipation of foam in t...

Embodiment 2

[0024] Embodiment 2: Raw ore grade: 2% to 5% zinc, 2. Processing capacity: 20 to 40t / h zinc oxide ore;

[0025] Introduce the non-delimed ore slurry of zinc oxide ore with a mass percentage concentration of 20% to 30% into the mixing tank, add 6 to 10 kg / t of sodium sulfide to adjust the slurry, and then add 300 to 600 g / t of 18 amine collector and zinc oxide Mineral reaction, the reacted pulp is introduced into the flotation machine, and No. 2 oil is added at 10-30g / t for flotation. Hydrophobic zinc oxide minerals are attached to the air bubbles and float on the liquid surface of the pulp to form a large amount of foam with poor fluidity. layer; the foam layer is quickly pushed into the foam tank of the flotation machine by using the double-sided bubble-discharging and quick-scraping mechanism, and then high-pressure water and high-pressure air are used to form jets to impact the foam, and the foam is transported to the foam pool; the foam flow rate is 0.6 cubic meters per sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com