Oil, gas and water three-phase liquid mixing device

A mixing device, water three-phase technology, applied in gas and water three-phase flow mixing device, downhole oil field, can solve the problems of reducing flow space, oil and gas production reduction, etc., achieving small pressure loss, convenient disassembly and assembly, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

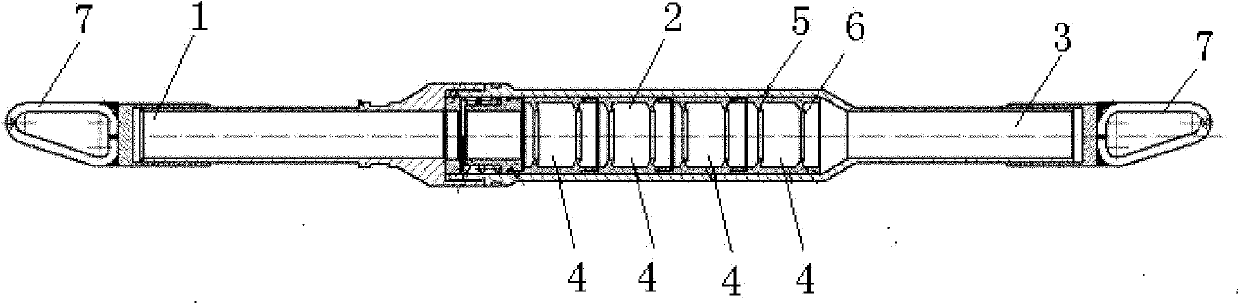

[0014] Such as figure 1 As shown, the present invention includes an upper joint 1 for threaded connection with the oil pipeline, the other end of the upper joint 1 is threaded with a turbulence device 2, the other end of the turbulence device 2 is threaded with a lower joint 3, and the other end of the lower joint 3 is used for Connect the oil outlet pipe with thread.

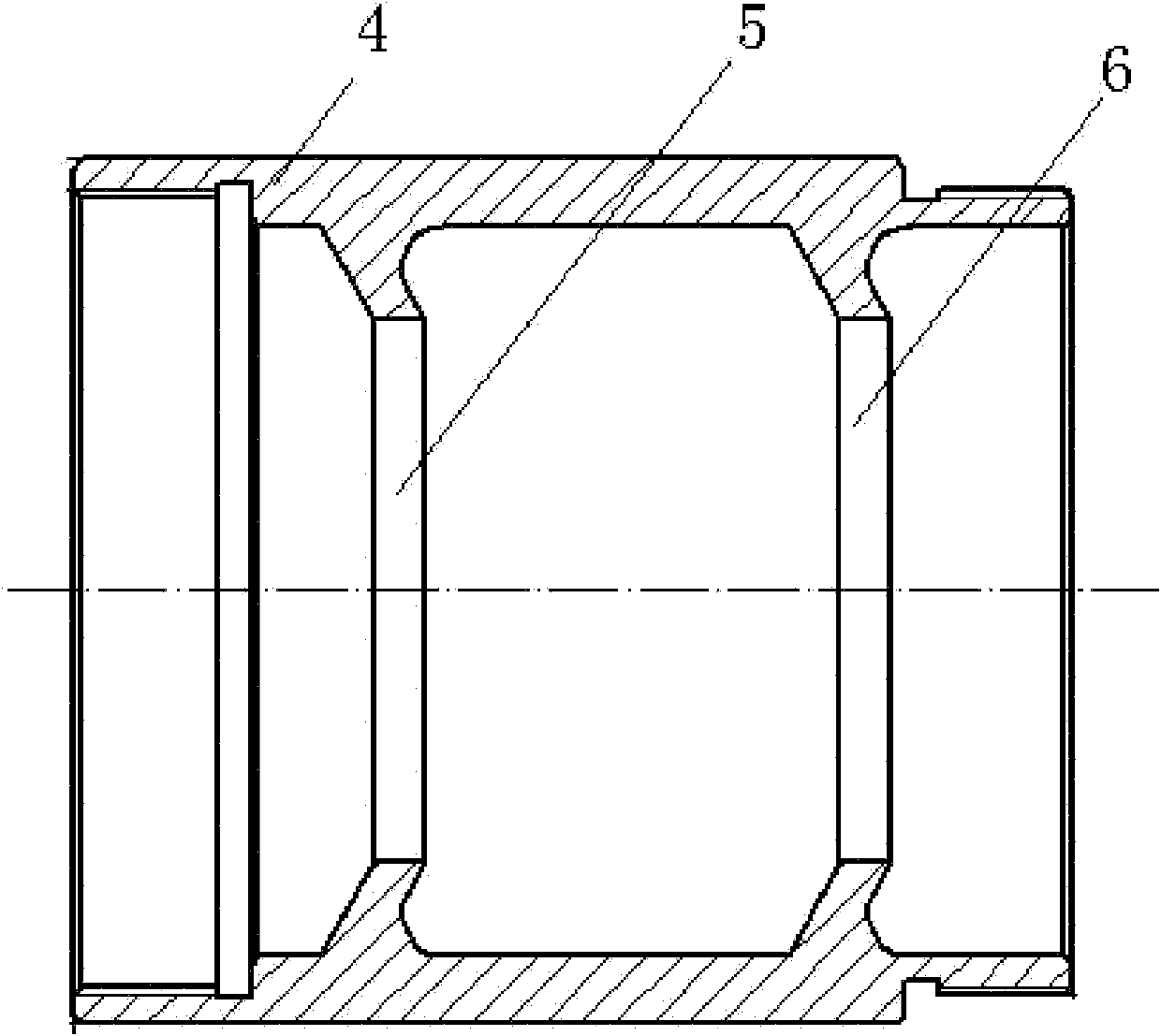

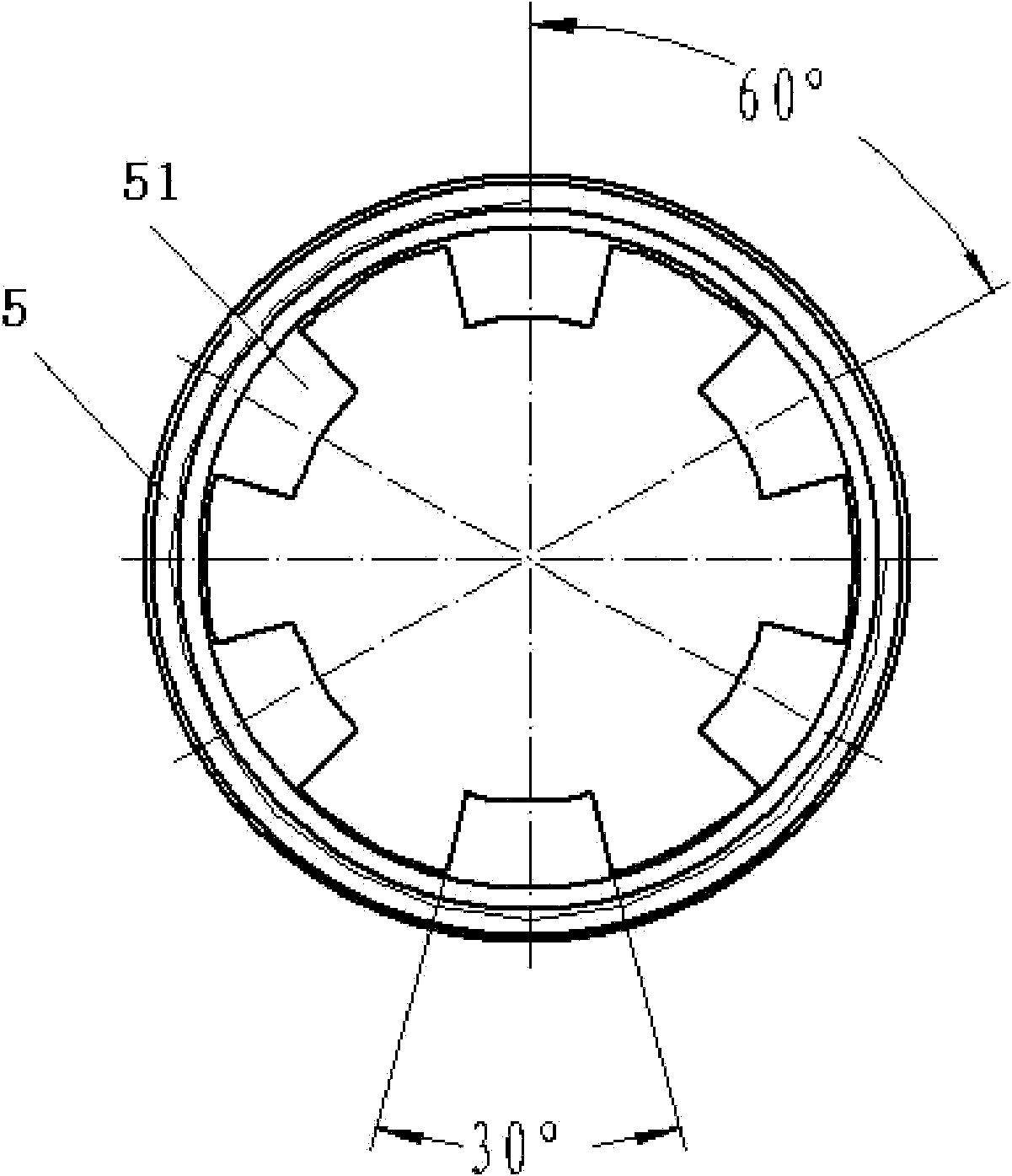

[0015] Such as figure 1 , figure 2 As shown, the turbulence device 2 includes a number of disturbing flow sleeves 4 connected by threads, each of the turbulence sleeves 4 has the same structure, and a cylindrical central through hole is arranged in it, and the inner diameter of the central through hole is the same as that of the oil delivery pipe and the oil outlet pipe. The inner diameters are the same, and a first baffle disk 5 and a second baffle disk 6 are arranged at intervals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com