Process for extracting tea polyphenol

An extraction process, tea polyphenols technology, applied in the field of tea polyphenols extraction process, can solve the problems of large pollution, active ingredient loss, solvent loss, etc., and achieve the effects of reducing production costs, improving product quality, and increasing extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

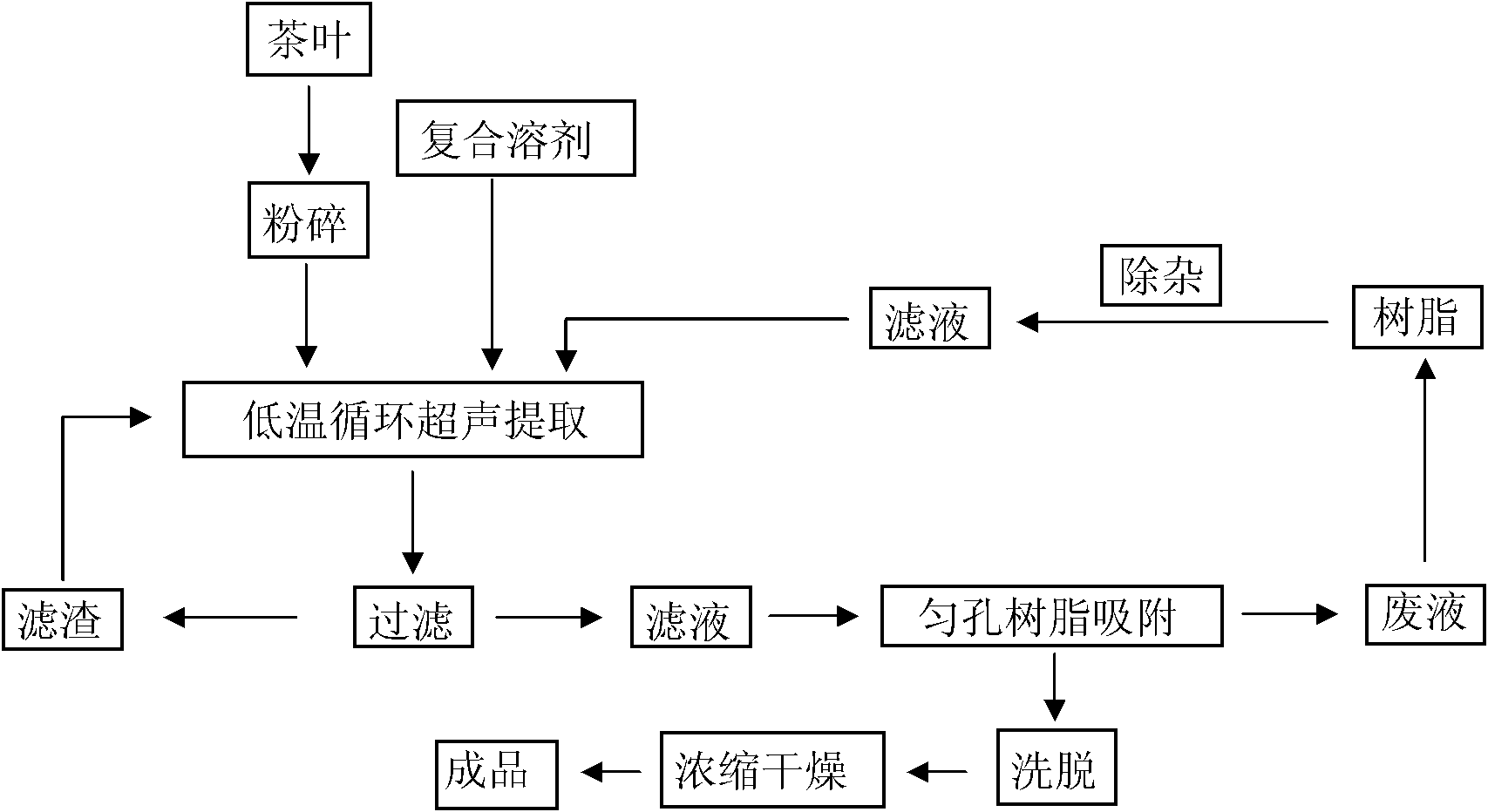

[0032] Such as figure 1 Shown, tea polyphenol extraction process comprises the following steps:

[0033] Step 1: Pulverize the tea raw materials into uniform particles;

[0034] Step 2: Extract the uniform tea leaves in step 1 with low-temperature circulating ultrasonic wall-breaking composite solvent,

[0035] Extract the tea polyphenol solution containing the residue;

[0036] Step 3: Filtrating the tea polyphenol solution containing residue in step 2 to obtain filtrate and filter residue;

[0037] Step 4: The filtrate in the step 3 is adsorbed through the uniform pore resin to obtain the resin and the

[0038] waste liquid, and then the resin for absorbing tea polyphenols is eluted to obtain a tea polyphenol eluent;

[0039] Step 5: Concentrating the tea polyphenol eluate in Step 4 under reduced pressure to form a finished product.

[0040] The low-temperature circulating ultrasonic wall-breaking composite solvent extraction in the step 2 includes the following steps: ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com