Improvements in or relating to rolls

A technology of dehydration roll, bottom layer, applied in the treatment of textile materials, liquid/gas/vapor removal with squeeze roll, squeezer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

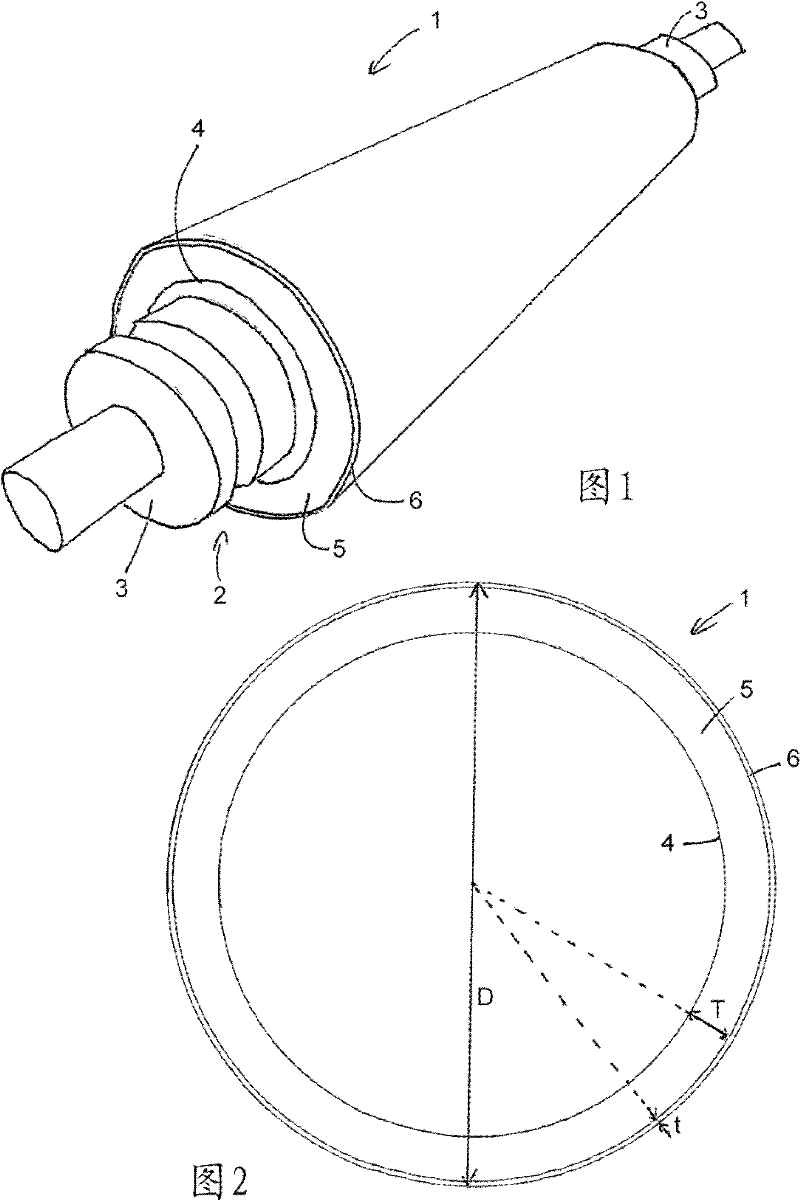

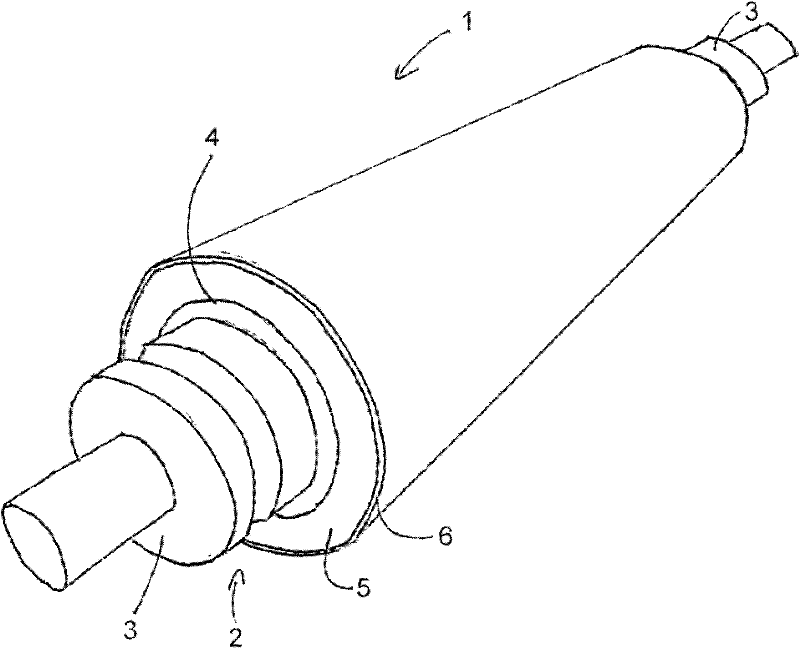

[0025] First refer to figure 1 , shows a squeeze roll 1 according to the invention. The roll comprises an elongated central shaft 2, usually made of solid metal, and most preferably steel. The shaft 2 is provided at both ends with short journals 3 configured for engagement with and supported by cooperating bearings provided in the dehydrator (not shown). It will be clear that the shaft 2 may be made of solid metal or tubular metal, or in a form comprising a solid metal core disposed within a protruding metal tube, as is known for providing variable pressure rolls or anti-deflection rolls. Alternatively, the shaft may be made of composite material such as carbon fiber material.

[0026] Between the two journals 3 the shaft 2 has an elongated central portion 4 with a substantially uniform circular cross-section.

[0027] Around the central roller portion 4 of the shaft 2 is provided an elastic bottom layer 5 formed of elastic material, which thus has a generally tubular confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com