Air-tight-seal MMW (millimeter wave) coaxial connector and assembly method thereof

A technology of coaxial connector and assembly method, which is applied in the direction of two-part connection device, connection, assembly/disassembly of contact pieces, etc., can solve the problems that cannot meet the requirements of broadband transmission and air sealing at the same time, and achieve excellent radio frequency performance, The effect of avoiding high costs and reducing the number of discrete steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

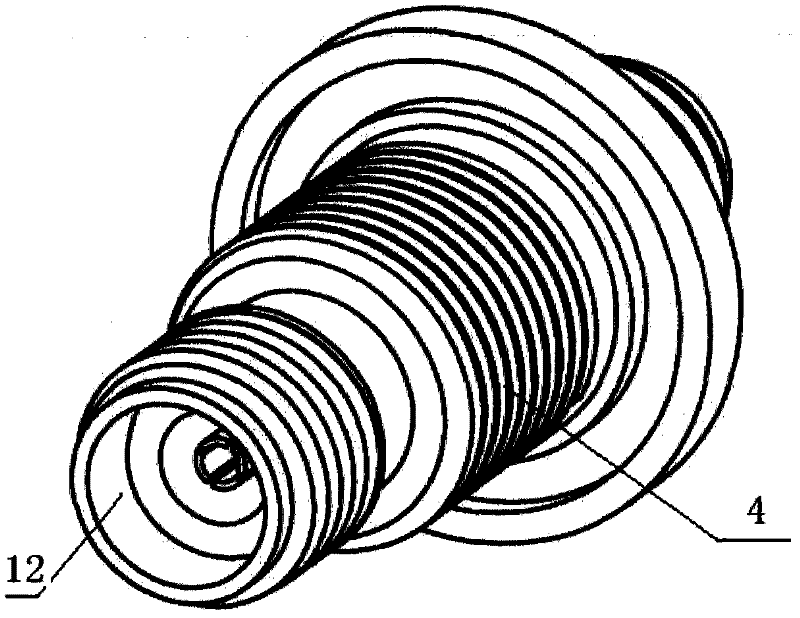

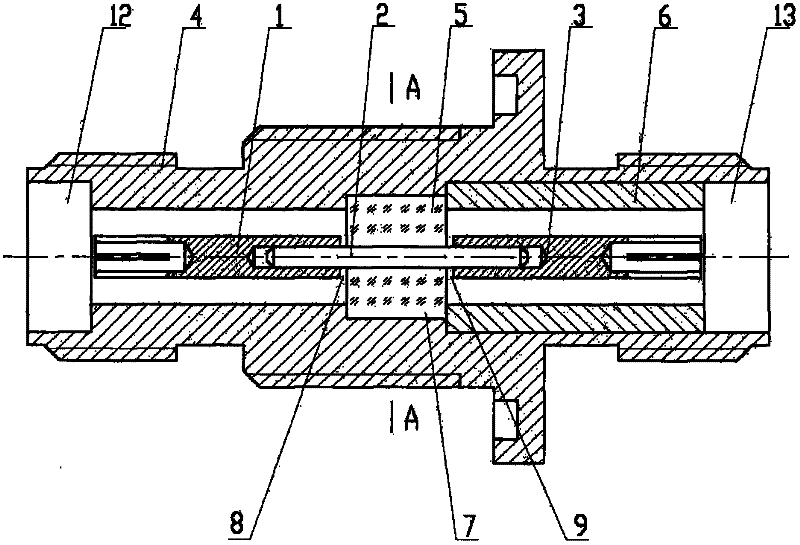

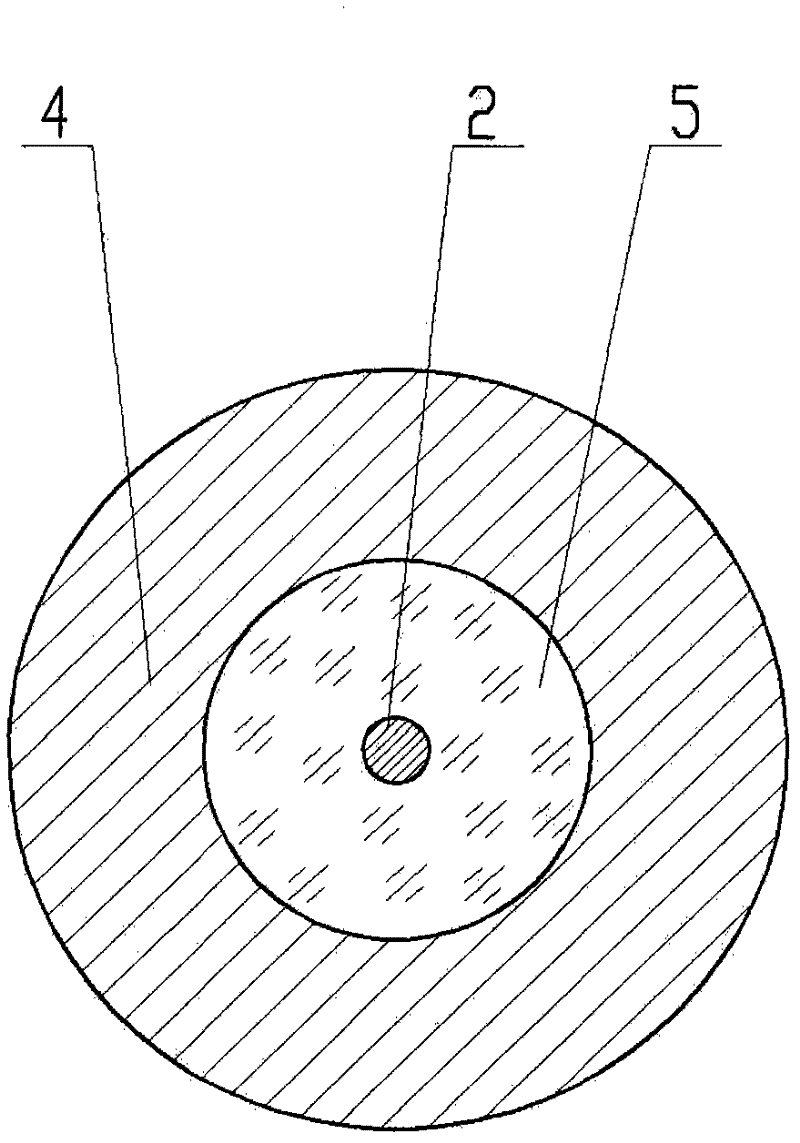

[0026] Such as figure 1 Shown is the outline drawing of the millimeter-wave coaxial connector of the present invention, figure 2 Shown is a structural cross-sectional view of the millimeter-wave coaxial connector of the present invention. It can be seen from the figure that the millimeter-wave coaxial connector of the present invention is a cylindrical structure, including an inner conductor assembly, an outer conductor assembly, an intermediate insulator 5 and an outer conductor assembly respectively The first connection terminal 12 and the second connection terminal 13 at both ends, wherein the inner conductor assembly includes the inner conductor pin 2, the first inner conductor jack 1 and the second inner conductor jack 3, the two inner conductor pins 2 The ends are inserted into the first inner conductor insertion hole 1 and the second in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com