Straight tube multi-axis ratchet wheel strain testing system and method

A test method and straight tube technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measuring device, etc., can solve the problems of insufficient data collection accuracy, inaccurate test position positioning, limited test channels, etc., to achieve flexible test position, The test position can be adjusted flexibly and the data curve is smooth and stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

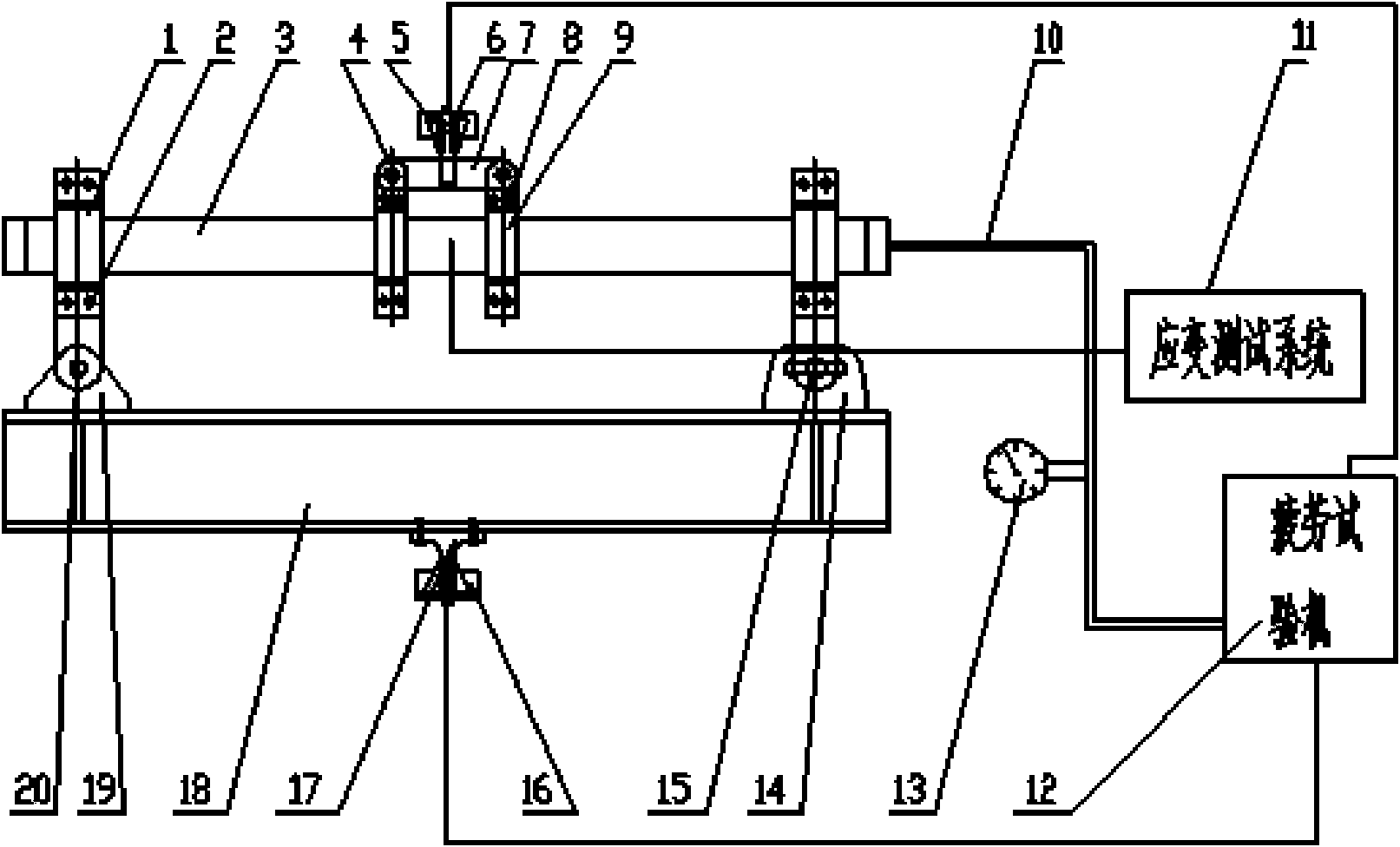

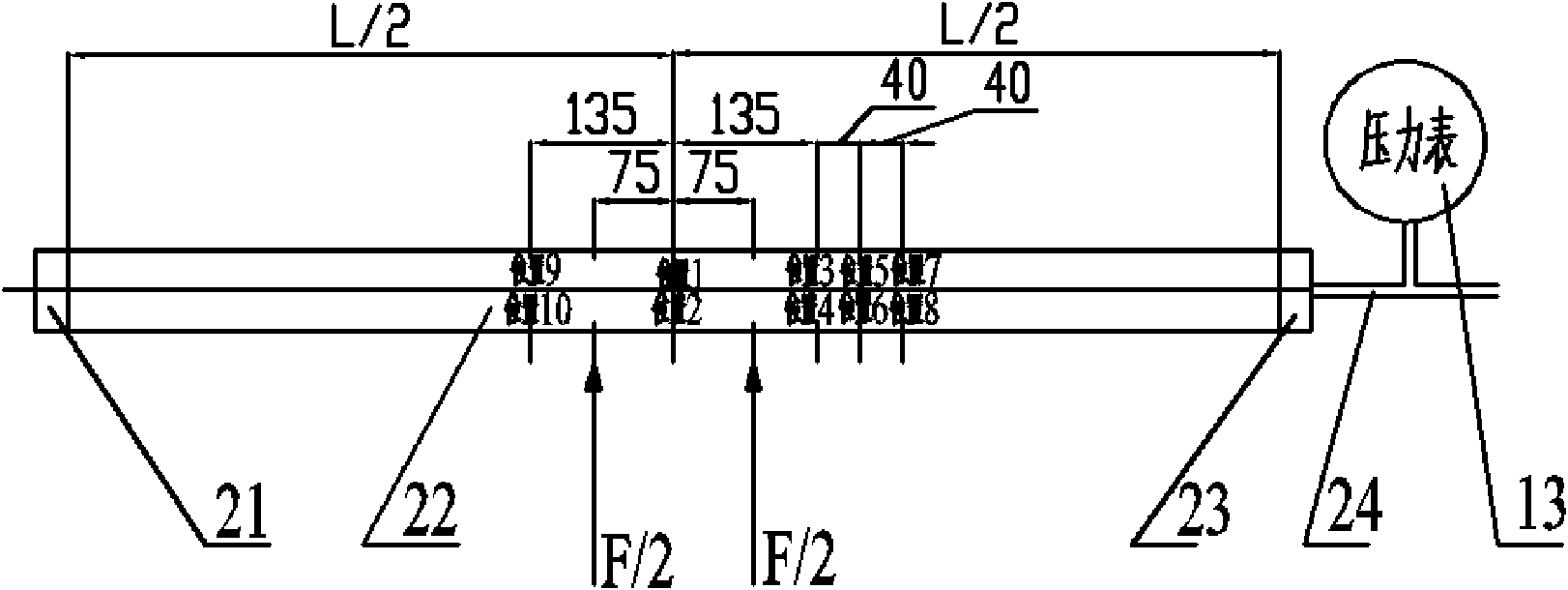

[0036] The invention realizes cyclic bending of internal pressure pipe fittings by using a multi-axis fatigue testing machine with quasi-three-point bending fixture auxiliary mechanism, and uses precision strain gauges to measure the ratchet strain of straight pipe samples. The instruments used in this test method include a designed straight tube sample 3, a multi-axis fatigue testing machine 12, a multi-channel dynamic strain measuring instrument 11 and other auxiliary mechanisms. The design straight pipe sample 3 is mainly composed of two parts, one is a straight pipe section 22 with a length of 1 m, and the other is two straight pipe plugs 21 and 23 with a length of 0.1 m, wherein the pipe plug 21 is completely closed, and the other end is straight. There is a threaded through hole in the center of the pipe plug 23 as an oil port. This oil port is connected to one end of the tee joint 24. A pressure gauge 13 can be installed on the tee joint to observe the pressure in the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com