Process for degreasing low methoxyl pectin

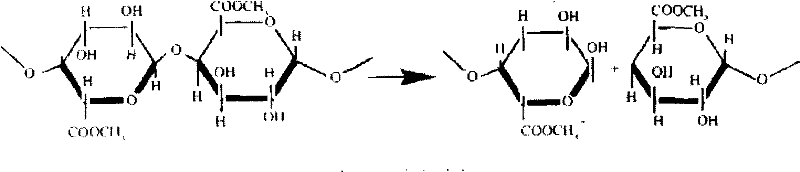

A low-methoxyl pectin and deesterification technology, which is applied in the deesterification process of pectin and the field of deesterification process of low methoxyl pectin, can solve the problem of low gum content, lower pectin gelation degree and esterification Problems such as chemical degree, pectin destruction, etc., achieve the effect of reducing production cost, improving production efficiency and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

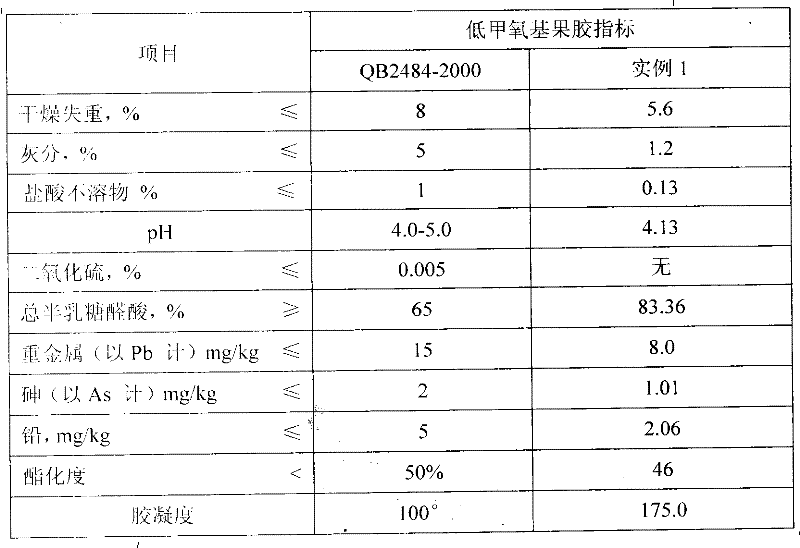

Embodiment 1

[0020] Example 1, the apple pomace crushed to 60 mesh and 70°C water were soaked and stirred for 50 minutes at a weight ratio of 1:20 to remove part of the pigment, and the cleaned pomace was squeezed to a water content of 75%; and then mixed with Water is mixed at a weight ratio of 1:20, acid is added to adjust the pH value to 2.0, and the temperature is kept at 70°C for 1.5 hours. After the extraction is completed, the extract and residue are separated and filtered and clarified through a leaf filter, and then the concentration ratio is doubled. , and concentrated in vacuo. Adjust the pH value of the obtained high-methoxyl pectin concentrate to 3.0, add pectin methylesterase at 0.5‰ of the weight of the pectin concentrate, keep warm at 30°C, and determine the holding time according to the degree of esterification required by the product. After the deesterification is completed, the pH value of the pectin solution is adjusted to 4.0, 50% alcohol preheated to 30°C and the pect...

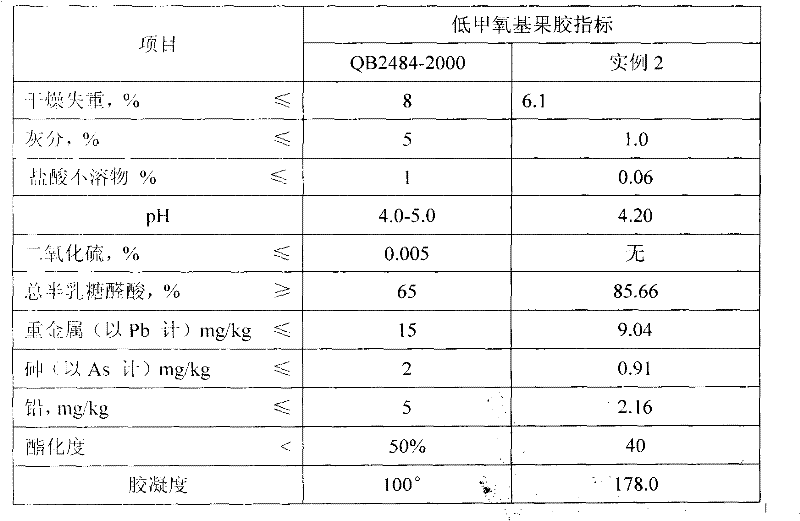

Embodiment 2

[0023] Example 2, the apple pomace crushed to 60 mesh and 70°C water were soaked and stirred for 50 minutes at a weight ratio of 1:20 to remove part of the pigment, and the cleaned pomace squeezer was pressed to a water content of 75%; and then mixed with Water is mixed at a weight ratio of 1:20, acid is added to adjust the pH value to 2.4, and the temperature is kept at 80°C for 2.5 hours. After the extraction is completed, the extract and residue are separated and filtered and clarified by a leaf filter, and then the concentration ratio is 2.4 times. , and concentrated in vacuo. Adjust the pH value of the obtained high methoxyl pectin concentrate to 3.9, add pectin methylesterase at 0.5‰ of the weight of the pectin concentrate, keep warm at 40°C, and determine the holding time according to the degree of esterification required by the product. After the deesterification is completed, adjust the pH value of the pectin solution to 4.2, mix and stir the 50% alcohol preheated to ...

Embodiment 3

[0026] Example 3, the apple pomace crushed to 60 mesh and 70°C water were soaked and stirred for 50 minutes at a weight ratio of 1:20 to remove part of the pigment, and the cleaned pomace was squeezed to a water content of 75%; and then mixed with Water is mixed at a weight ratio of 1:20, acid is added to adjust the pH value to 2.9, and the temperature is kept at 90°C for 5 hours. After the extraction is completed, the extract and residue are separated and filtered and clarified by a leaf filter, and then the concentration ratio is 4 times. Concentrate in vacuo. Adjust the pH value of the obtained high-methoxyl pectin concentrate to 5.0, add pectin methylesterase at 0.5‰ of the weight of the pectin concentrate, keep warm at 50°C, and determine the holding time according to the degree of esterification required by the product. After the deesterification is completed, the pH value of the pectin solution is adjusted to 5.0, 50% alcohol preheated to 50°C and the pectin solution ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com