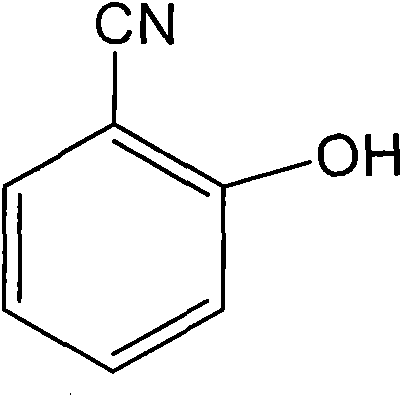

Method for preparing 2-hydroxybenzonitrile from ammonium salicylate as raw material

A technology of o-hydroxybenzonitrile and ammonium salicylate, applied in the preparation of ammonia-carboxylic acid reaction, organic chemistry, etc., can solve the problem of low content of o-hydroxybenzonitrile, low conversion rate of raw materials, many reaction steps, etc. problem, to achieve the effect of easy stirring and mixing, avoiding the sublimation and decomposition of salicylic acid, and less waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

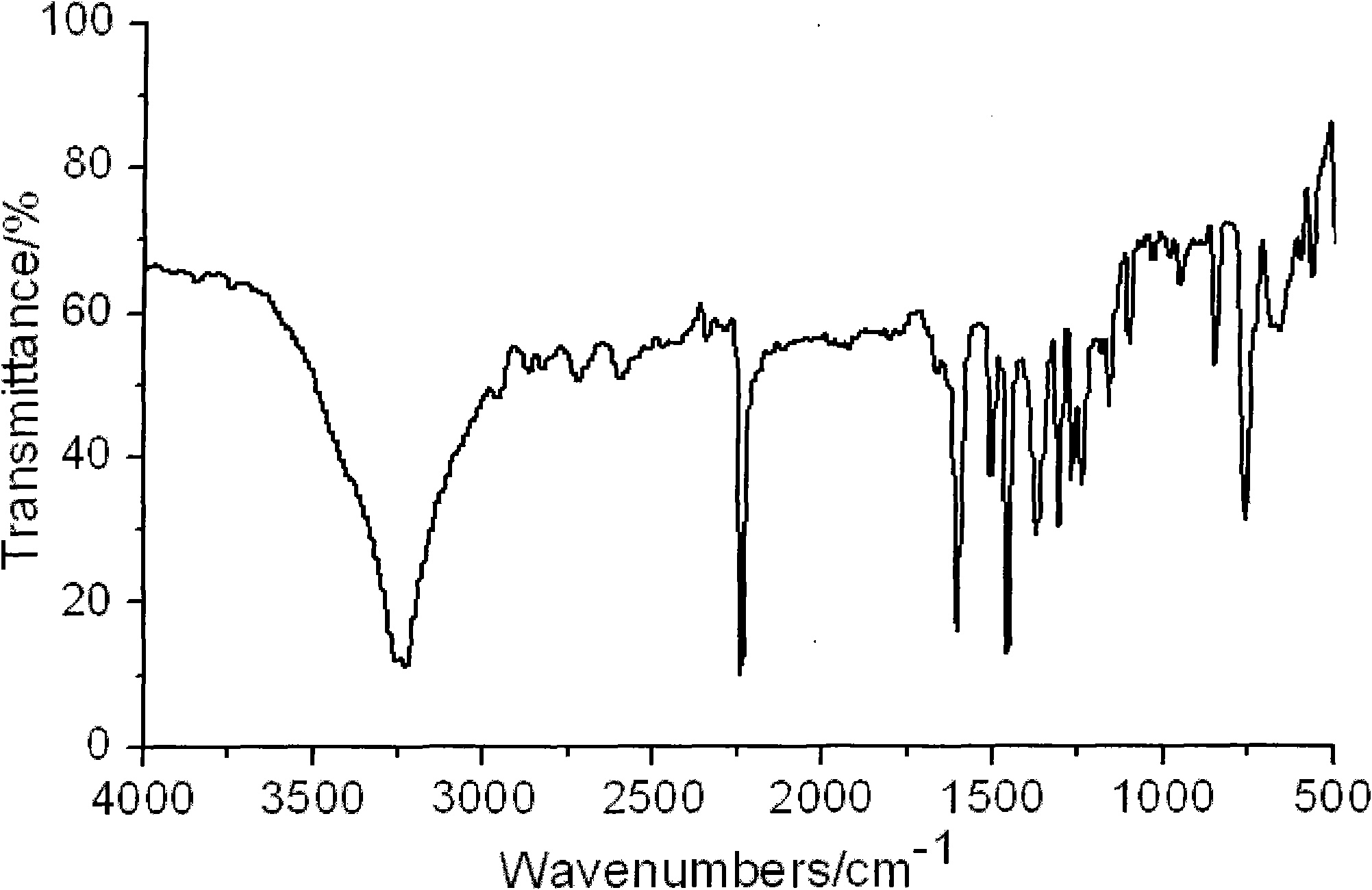

Image

Examples

Embodiment 1

[0020] After 138 grams of salicylic acid are made into slurry with 400 grams of water, feed ammonia or add ammoniacal liquor wherein, stir and make it form homogeneous solution, until the pH of solution is 8.0 and obtain the aqueous solution containing ammonium salicylate; After the ammonium salicylate solid obtained after the aqueous solution of ammonium salt is transferred to the reactor through evaporation concentration, crystallization, filtration or centrifugation, add 90 grams of urea, 97 grams of sulfamic acid and 1 gram of magnesium oxide, aluminum oxide, oxide Calcium, silicon oxide, artificial zeolite in m 氧化镁 :m 氧化铝 :m 氧化钙 :m 氧化硅 :m 人造沸石 =0.0001: 0.005: 0.8: 0.08: 1.0 constitutes a catalyst and 120 grams of o-cresol, p-cresol, ethylene glycol, methyl salicylate, diphenyl ether and dichlorophenol by m o-cresol Base phenol: m 对甲基苯酚 :m 一缩乙二醇 :m 水杨酸甲酯 :m 二苯醚 :m 二 氯苯酚 = 0.0001: 0.006: 0.0008: 9: 0.01: 0.12, stirring to form a mixed material; heating the mixed m...

Embodiment 2

[0022] After 138 grams of salicylic acid are made into slurry with 200 grams of water, feed ammonia or add ammoniacal liquor wherein, stir and make it form homogeneous solution, until the pH of solution is 9.0 and obtain the aqueous solution containing ammonium salicylate; The ammonium salicylate aqueous solution obtained after evaporation concentration, crystallization, filtration or centrifugation is transferred to the reactor after the solid ammonium salicylate, then add 105 grams of urea, 146 grams of sulfamic acid and 2 grams of magnesium oxide, aluminum oxide, oxide Calcium, silicon oxide, artificial zeolite in m 氧化镁 :m 氧化铝 :m 氧化钙 :m 氧 化硅 :m 人造沸石 =0.001: 0.05: 1.8: 0.8: 2.0 constitute the catalyst and 160 grams by m o-cresol, p-cresol, ethylene glycol, methyl salicylate, diphenyl ether and dichlorophenol Base phenol: m 对甲基苯酚 :m 一缩乙二醇 :m 水杨酸甲酯 :m 二 苯醚 :m 二氯苯酚 = 1.0: 0.6: 0.8: 3: 2.0: 6, stirring to form a mixed material; heating the mixed material to make the t...

Embodiment 3

[0024] After 138 grams of salicylic acid are made into slurry with 500 grams of water, feed ammonia or add ammoniacal liquor wherein, stir and make it form homogeneous solution, until the pH of solution is 10.0 and obtain the aqueous solution containing ammonium salicylate; After the ammonium salicylate solid obtained after the aqueous solution of ammonium salt is transferred to the reactor through evaporation concentration, crystallization, filtration or centrifugation, add 120 grams of urea, 194 grams of sulfamic acid and 5 grams of magnesium oxide, aluminum oxide, oxide Calcium, silicon oxide, artificial zeolite in m 氧化镁 :m 氧化铝 :m 氧化钙 :m 氧化硅 :m 人造沸石 =0.01: 0.5: 8: 8: 1.0 constitutes a catalyst and 180 grams of o-cresol, p-cresol, ethylene glycol, methyl salicylate, diphenyl ether and dichlorophenol by m o-cresol Base phenol: m 对甲基苯酚 :m 一缩乙二醇 :m 水杨酸甲酯 :m 二笨醚 :m 二氯苯酚 = 2.0: 0.6: 1.5: 1.9: 5.0: 3.0 of the solvent, stirring to form a mixed material; heating the mixed m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com