Impressing device for full-automatic corrugated cardboard box gluer

A corrugated box, fully automatic technology, applied in the field of the indentation device of the automatic corrugated box gluer, can solve the problems of high labor intensity, large number of workers, low automation procedures, etc. The effect of fast box speed and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

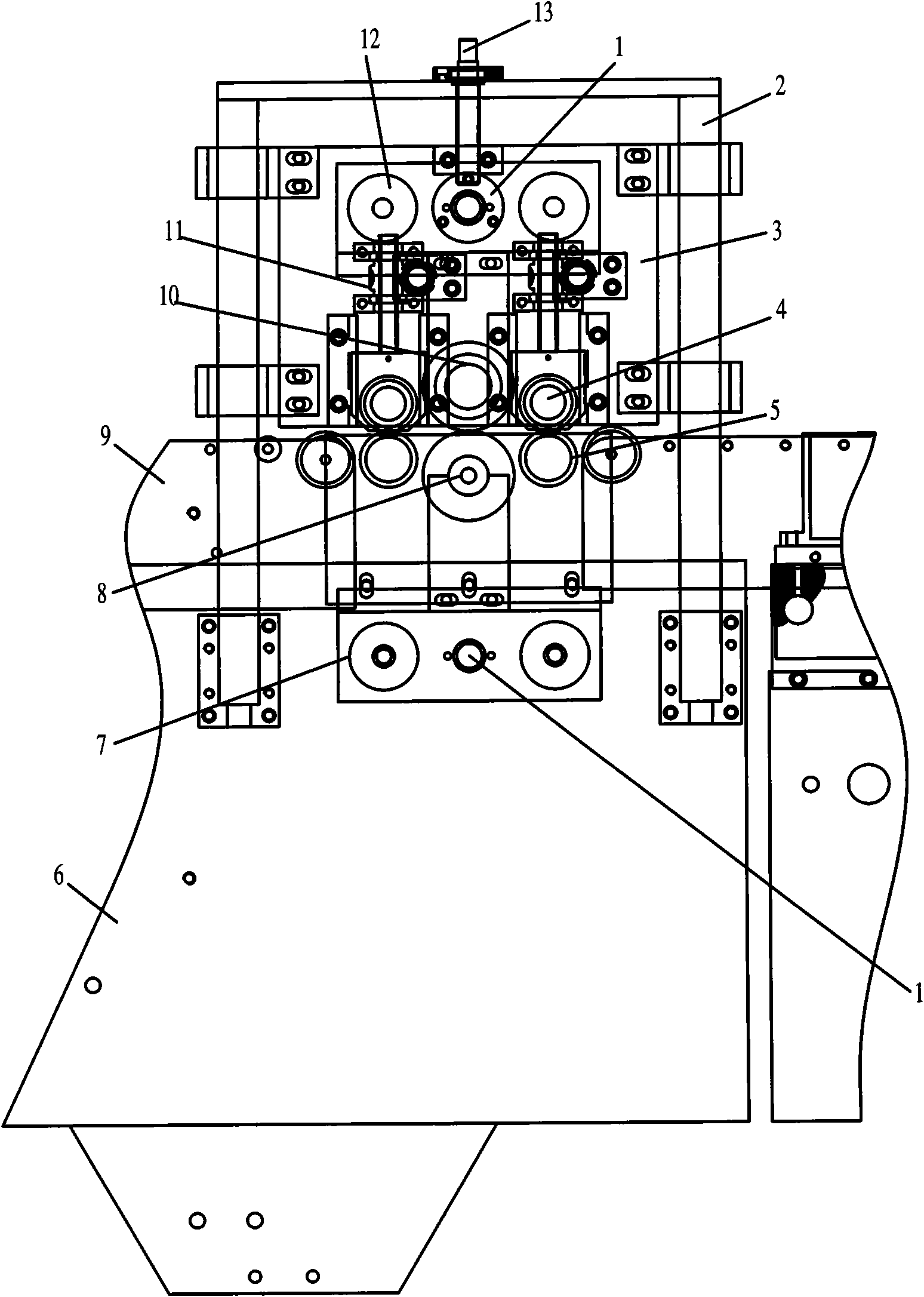

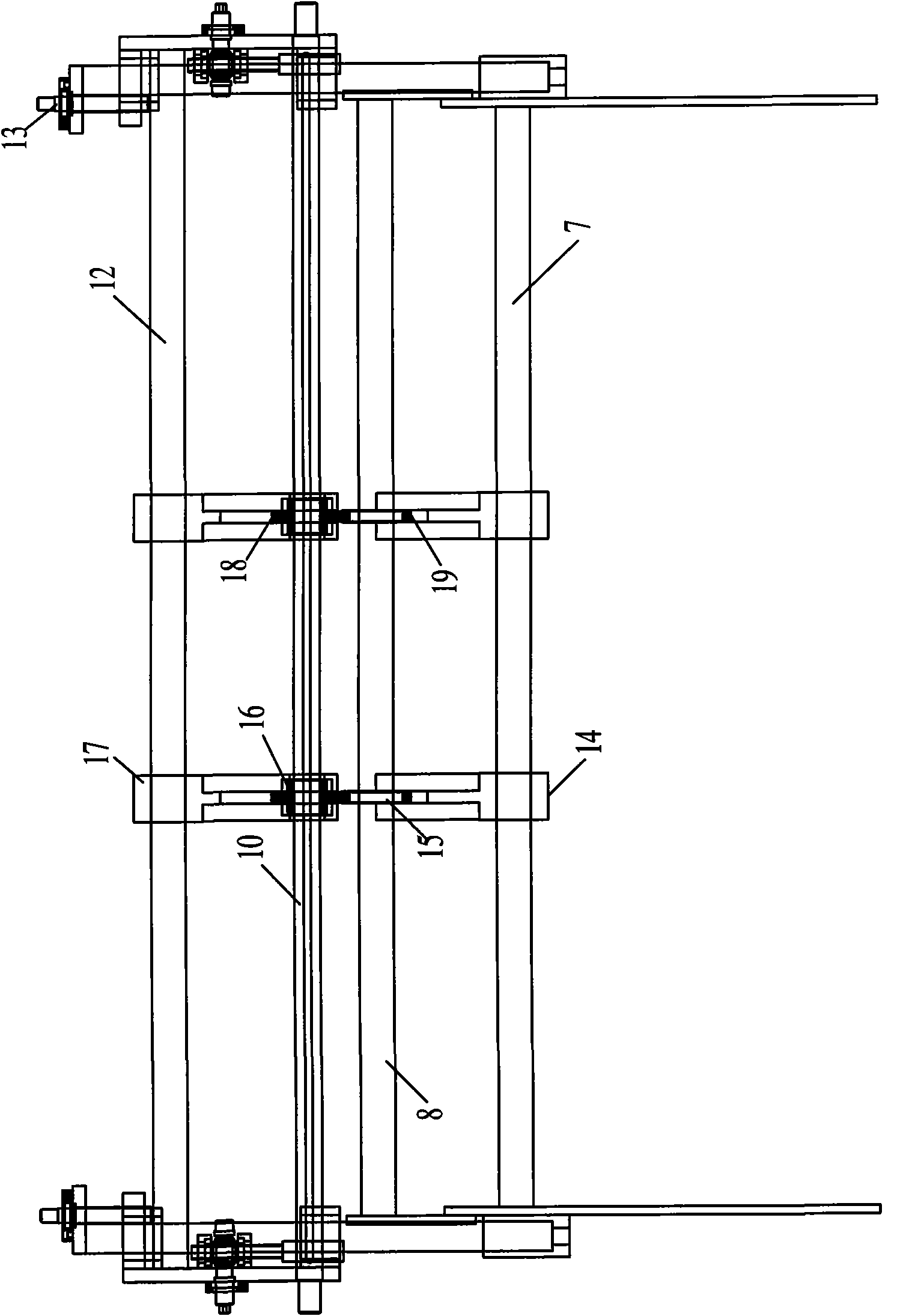

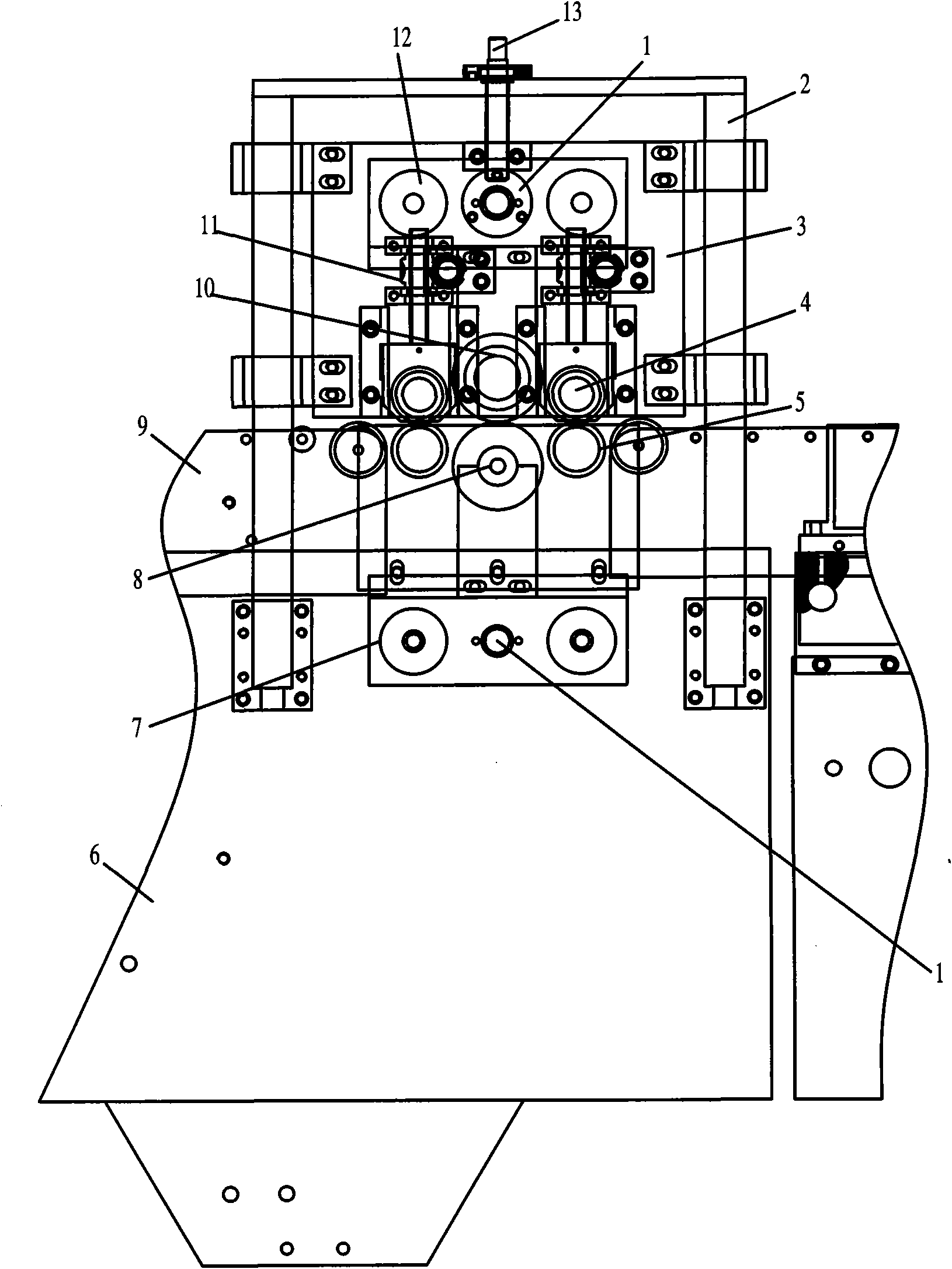

[0014] Such as figure 1 As shown, the indentation device of the automatic corrugated box folder-gluer related to the present invention includes two outer wall panels 6 and two pairs of rubber rollers, and the two outer wall panels 6 are fixed on the lower parts of both sides of the fuselage, including There are sliding guide columns 2, movable side plates 3, half support plates 9, supporting guide rails, positioning blocks, indentation shafts and indentation wheels. The sliding guide columns 2 are external wall panels 6 fixed on both sides in the vertical direction At the upper end, under the middle position of the two sliding guide columns 2 on the same side, there is a half support plate 9 fixed on the upper part of the outer wall panel 6, the movable side plate 3 is located above the half support plate 9, and is slidably arranged on two sliding guide posts 2. On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com