Method for detecting space position state of each circular member bar of jacket in three-dimensional coordinate system

A technology of spatial position and jacket, which is applied in the direction of measuring devices and instruments, and can solve problems such as inaccurate coordinates of the center of the circle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

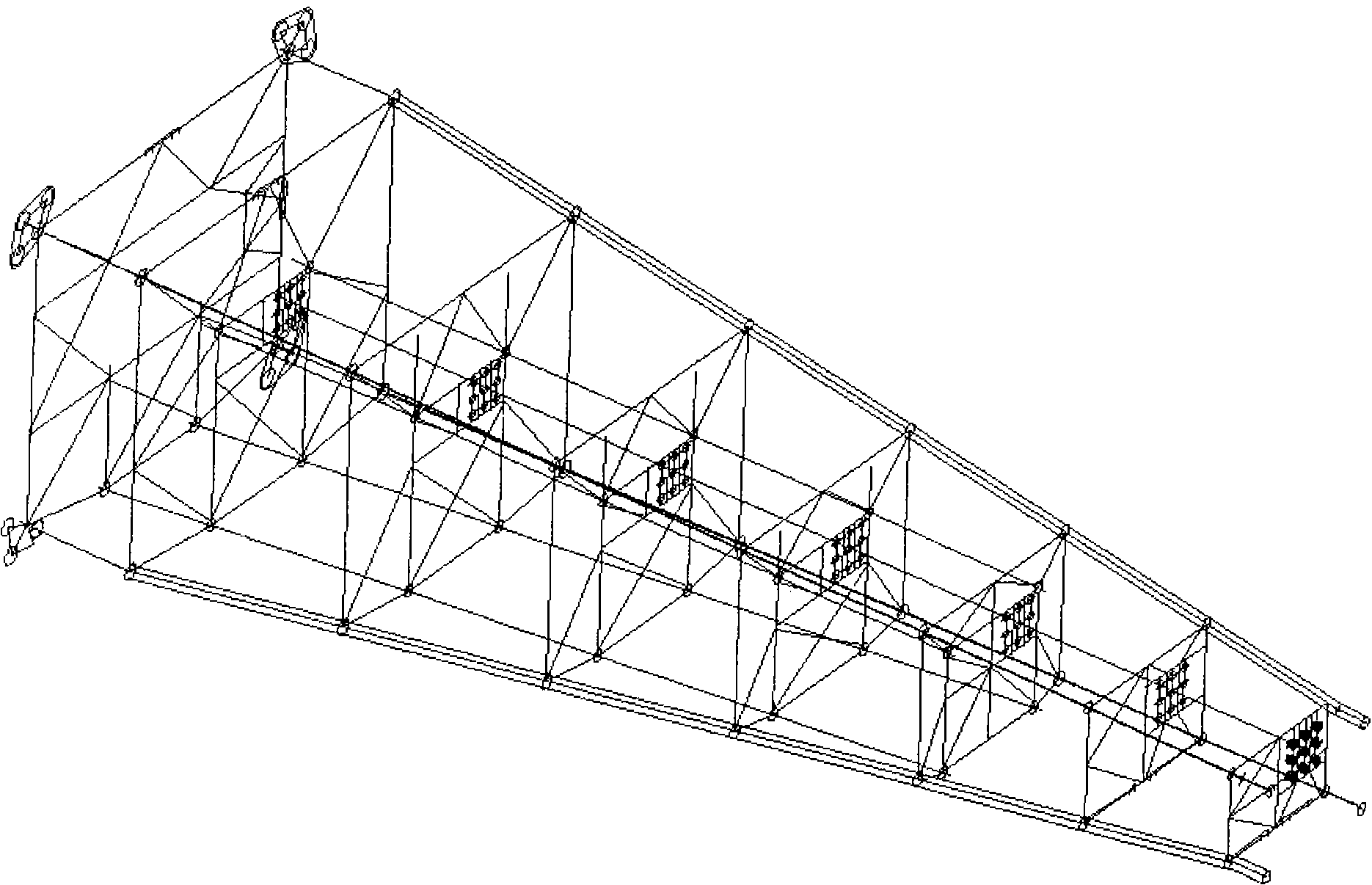

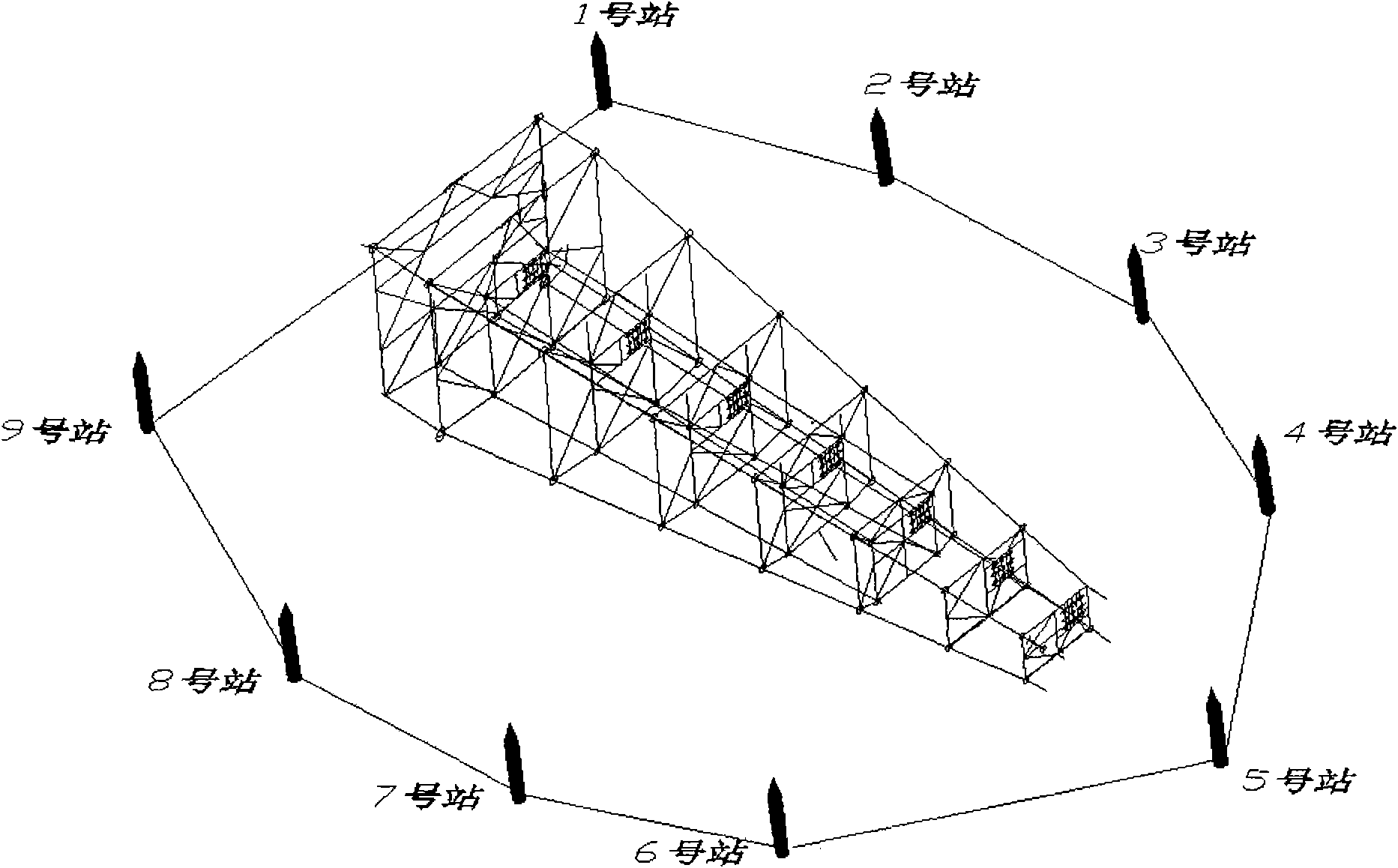

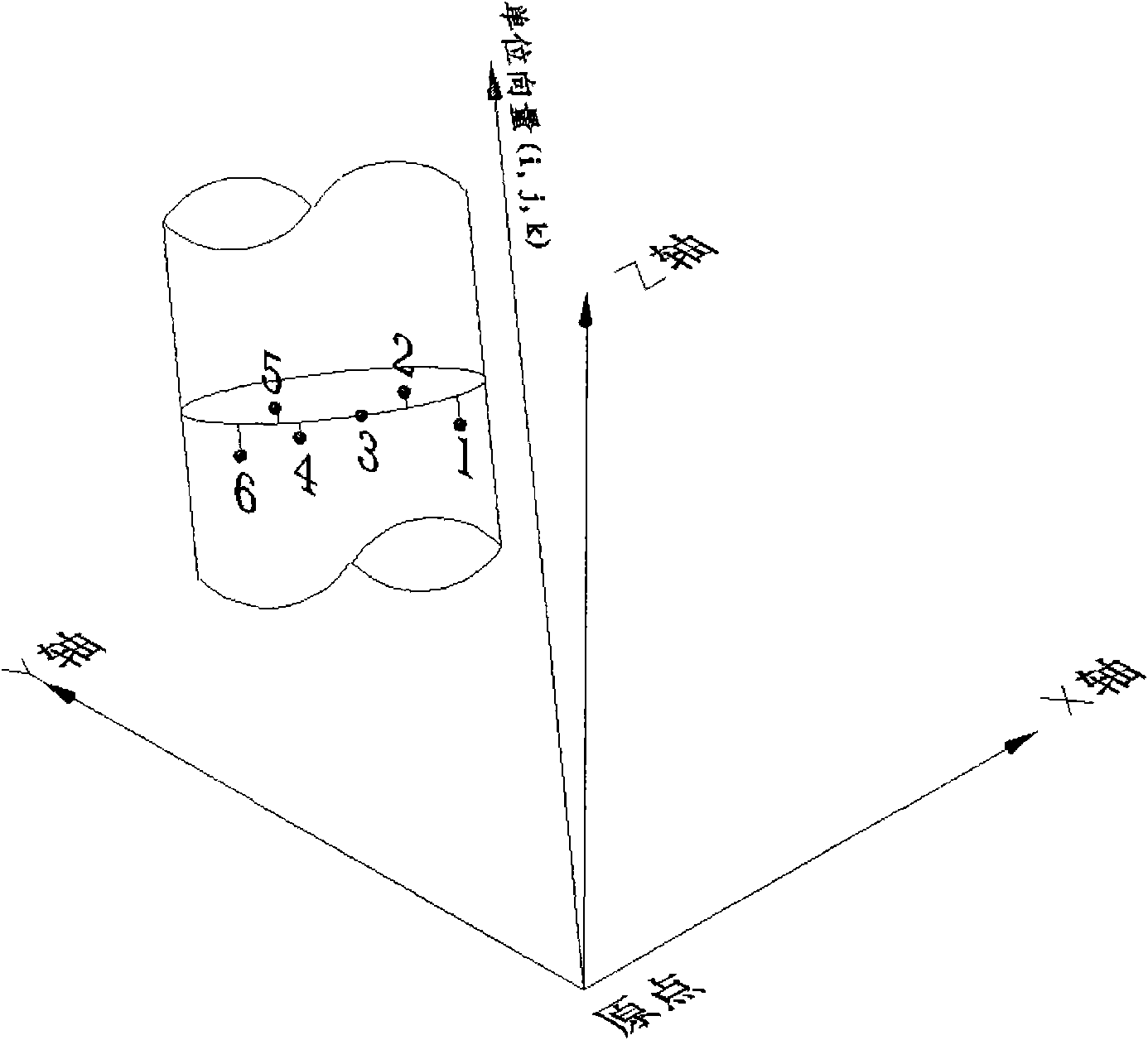

[0091] Such as figure 1 —— figure 2 As shown, in advance, a three-dimensional control network is set up around the jacket construction site; the specific steps are as follows:

[0092] 1) Determine the station locations of several three-dimensional control nets around the two parallel slideways at the jacket construction site, and the several stations should be evenly distributed around the slideways;

[0093] 2) Bury rocks and assemble the stations of the 3D control network. When assembling, the forced centering of the instrument should be considered, and the level of contact with the flange surface of the total station should be ensured as much as possible;

[0094] 3) Measure the corners and elevations of each site in the 3D control network, and use the control network adjustment software to calculate the site coordinates of each site to form a precise 3D control network;

[0095] 4) Combining the theoretical model of the jacket with the three-dimensional control network...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com