Lubricating device with automatic inflating and deflating pressure oil tank and oil tank inner lining

A technology of automatic filling and deflation, pressure oil tank, applied in the direction of engine lubrication, lubrication pump, lubrication parts, etc., can solve the problems of difficult to meet the pumping capacity, affect the operation, limited effect, etc., to achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

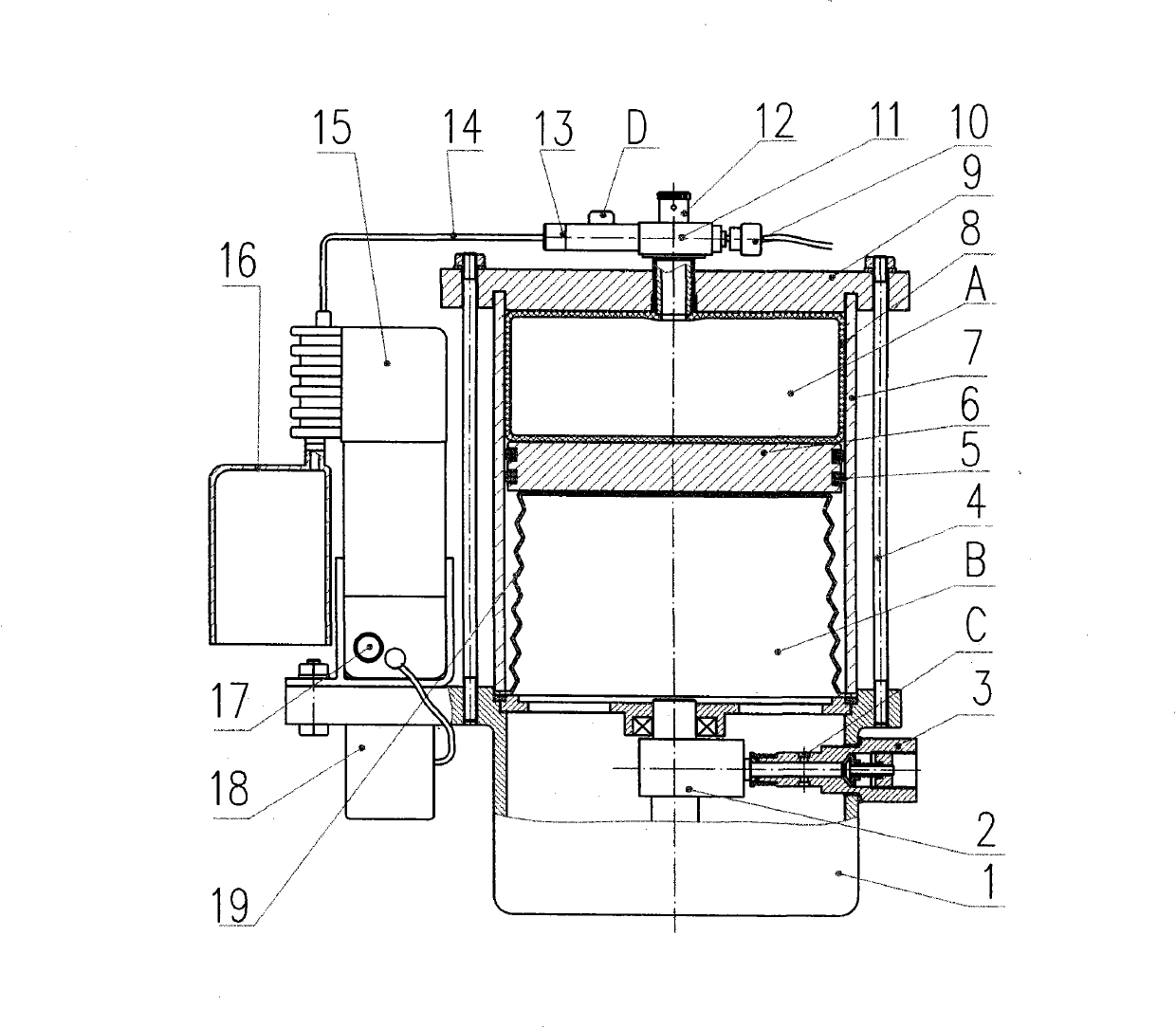

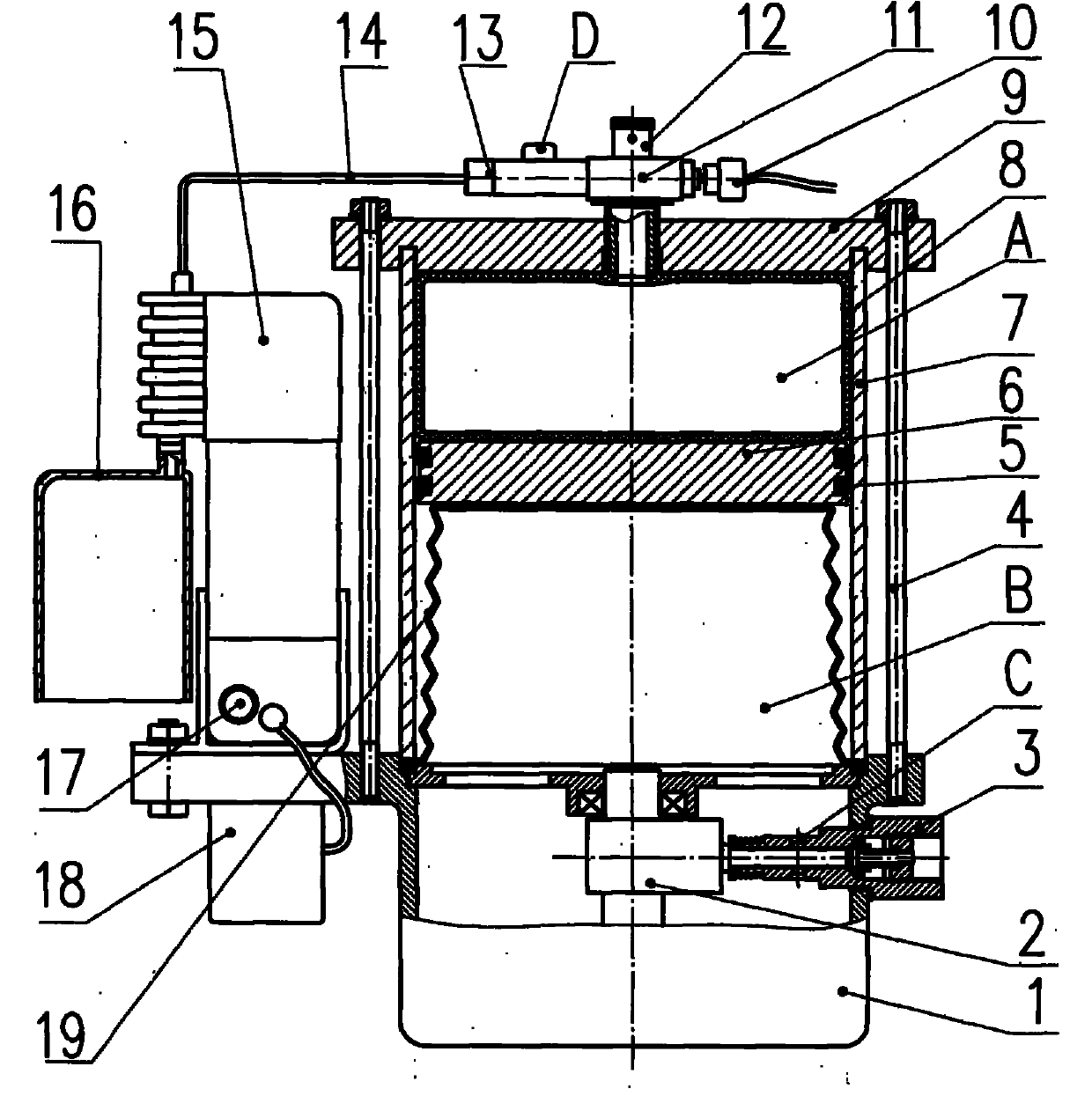

[0012] The present invention is further described below by accompanying drawing. In the structural schematic diagram of Embodiment 1 of the lubricating device with automatic inflation and deflation pressure oil tank and oil tank lining shown in the accompanying drawings, the lubricating pump housing 1, the cylindrical oil tank 7 and the upper cover 9 are compressed and fixed by four studs 4, Among them, the upper part of the lubricating pump housing 1 is sealed with the lower end of the cylindrical oil tank 7, the power assembly 2 and the lubricating pump 3 driven by it are installed on the lubricating pump housing 1, and the automatic controller 18 is fixed on the lubricating pump housing 1 On the top, the electric air pump 15 and the power assembly 2 are connected through the circuit to control the operation of the lubricating device. The cylindrical oil tank 7 is separated by the piston 6 and the sealing ring 5 into a mutually sealed upper chamber A of the fuel tank and a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com