Connecting device

A technology for connecting devices and connecting parts, which is applied to fixtures, mechanical equipment, etc., can solve the problems of difficulty in ensuring the accuracy of external dimensions, time-consuming, and affecting the flatness of the surface of the LED display.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

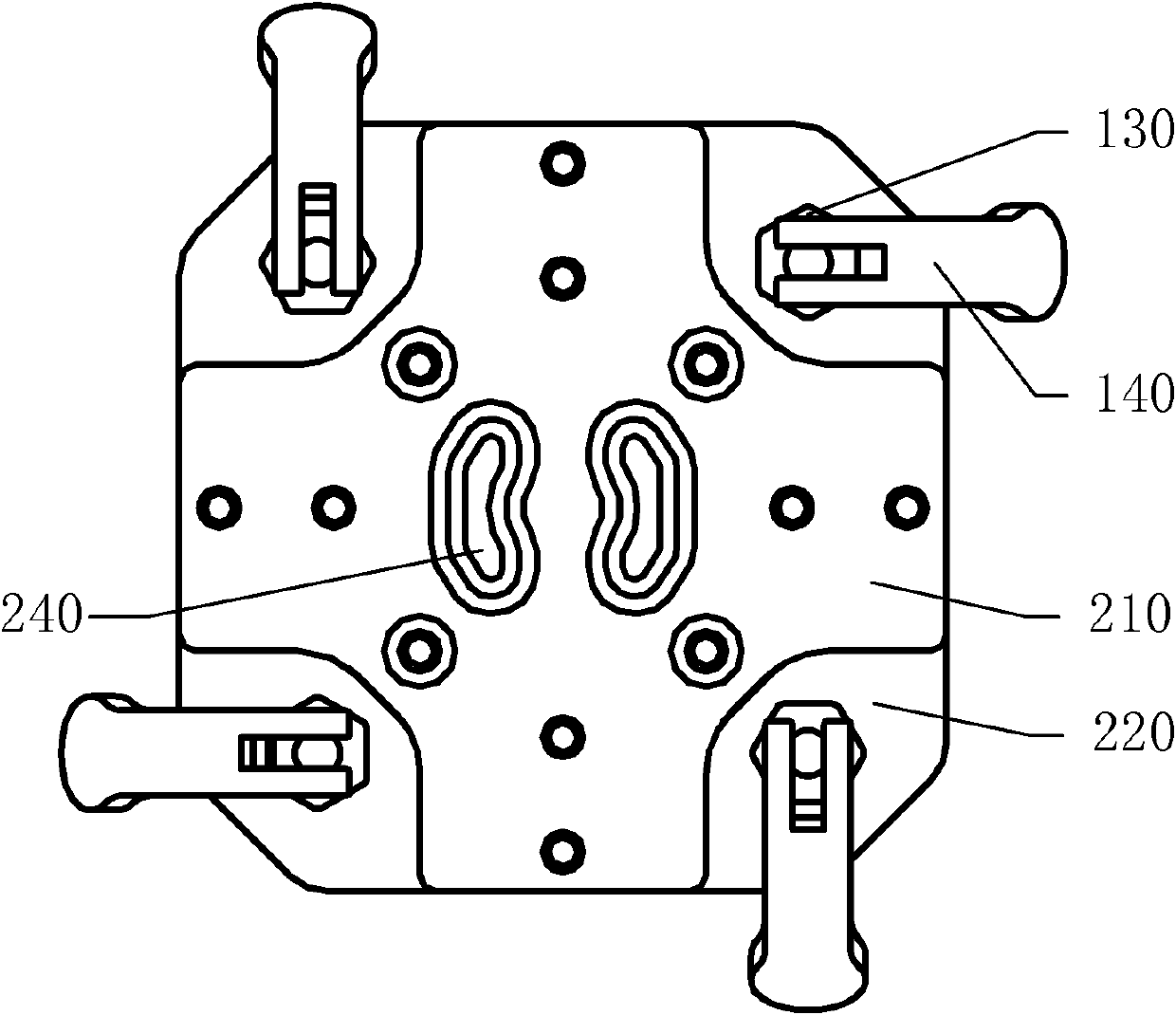

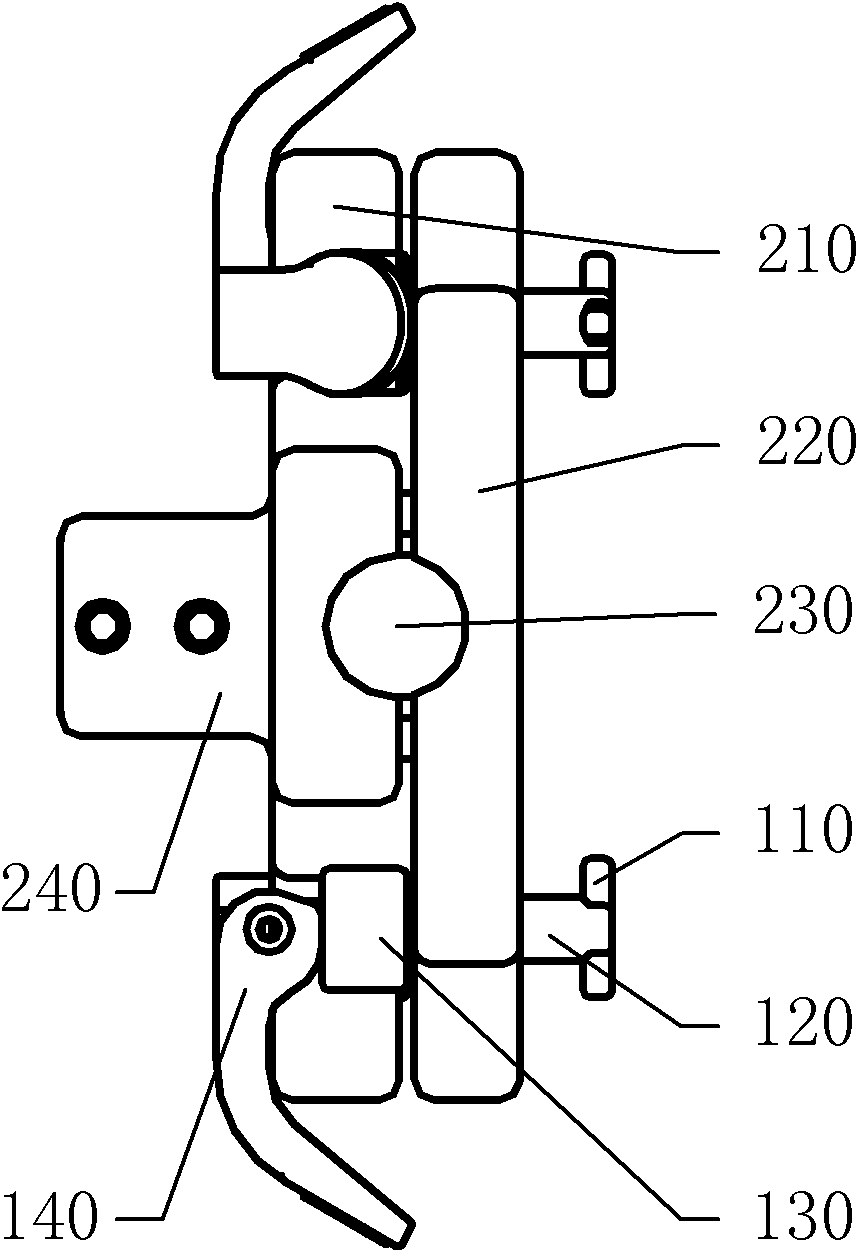

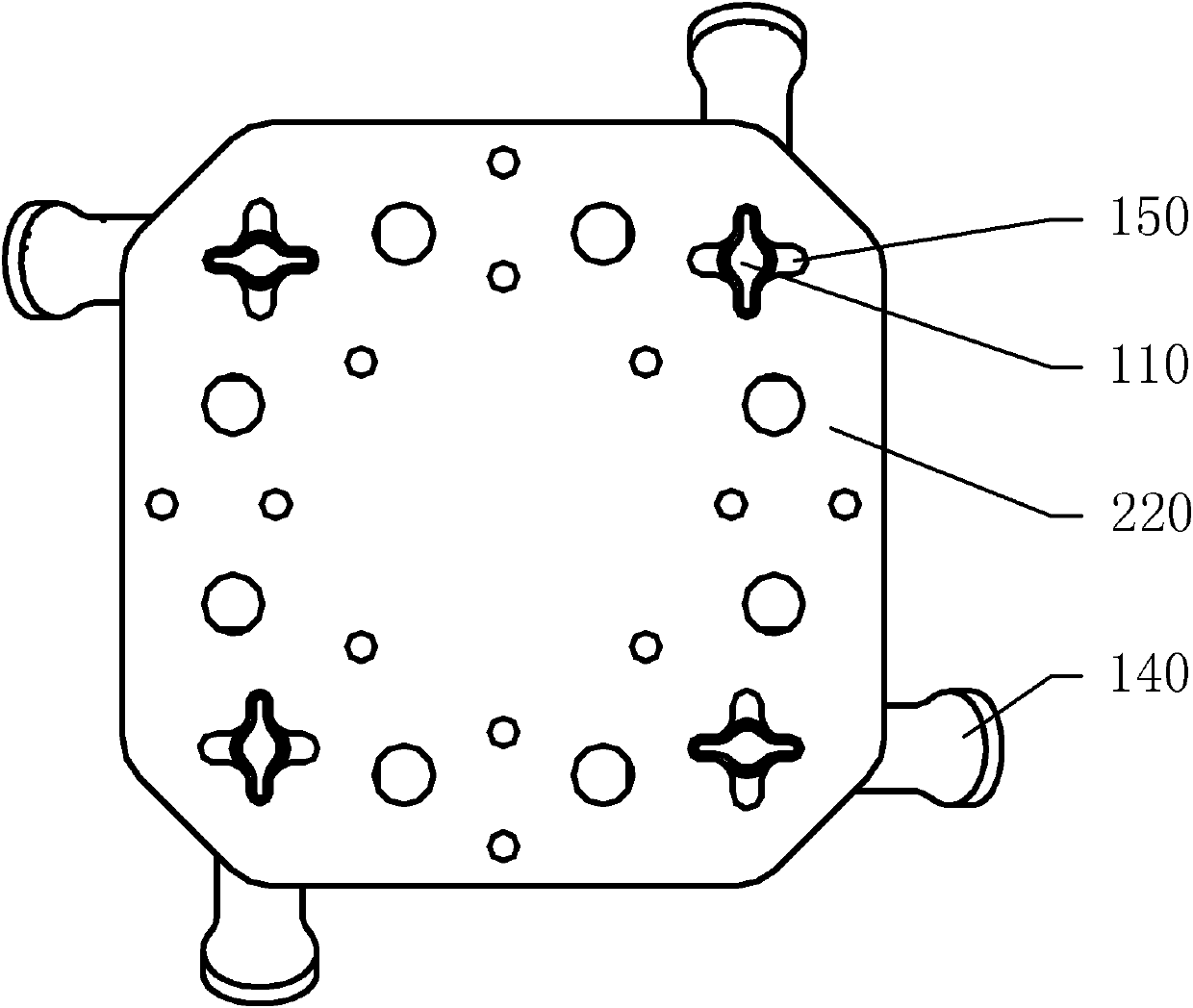

[0016] Such as Figure 1 to Figure 5 As shown, the connecting device of this embodiment includes: a base plate, a fixing piece for fixing the part 300 to be connected on the base plate; not shown). The non-circular end buckle 110 is fixedly arranged on one end of the shaft 120 , the limiting part 130 is arranged on the other end of the shaft 120 , and the spring is fixed on the shaft 120 and located between the non-circular end buckle 110 and the limiting part 130 . Both the to-be-connected part 300 and the base plate are provided with a buttonhole 150 that is compatible with the non-circular end button 110 , and the buttonhole 150 can accommodate the rotation of the shaft 120 in the buttonhole 150 .

[0017] Take the base plate and the part to be connected 300 placed horizontally, and the operating surface is on the top as an example for i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com