Flexible alumina ceramic fiber and preparation method thereof

A technology of alumina ceramics and ceramic fibers, which is applied in the field of fiber materials and can solve problems such as low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

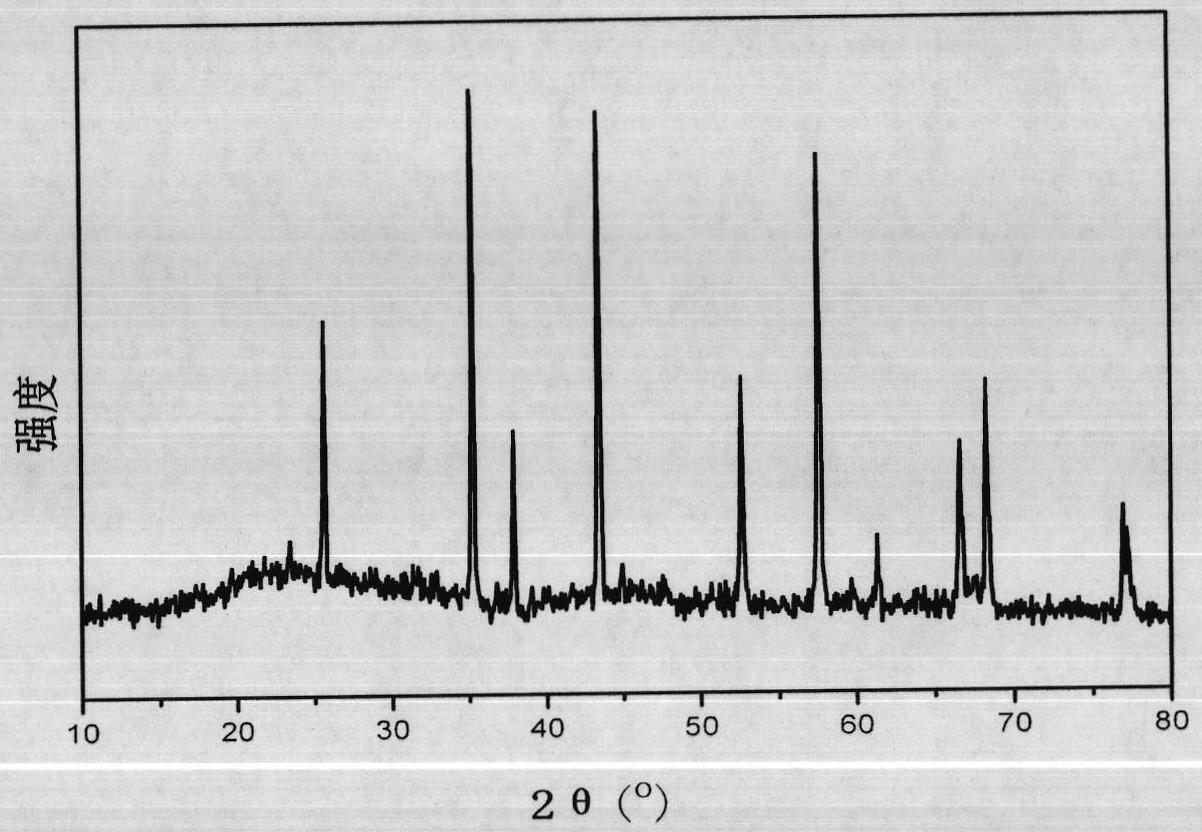

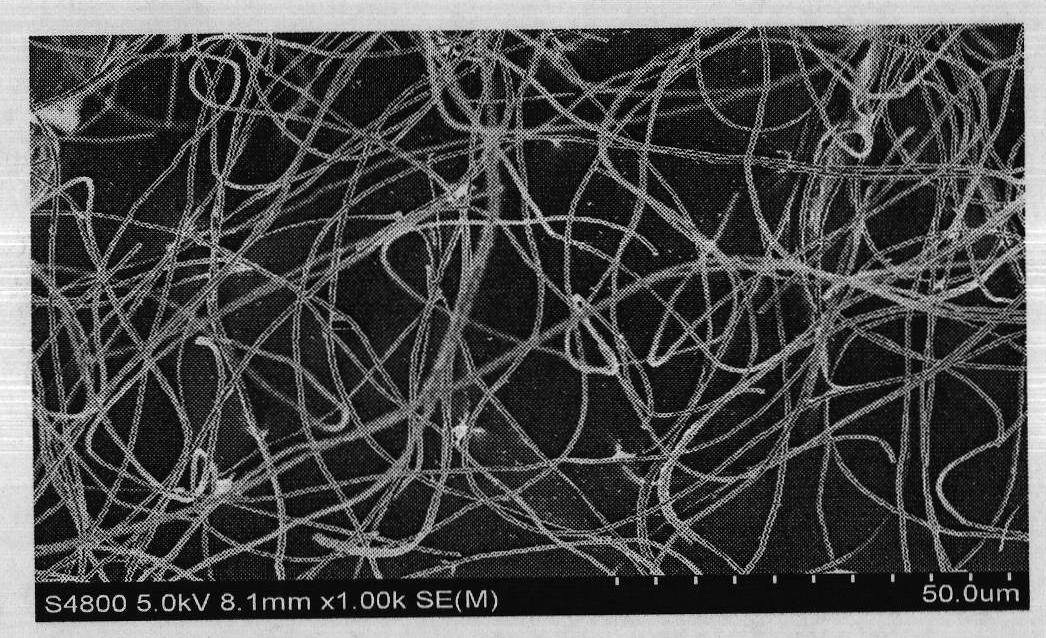

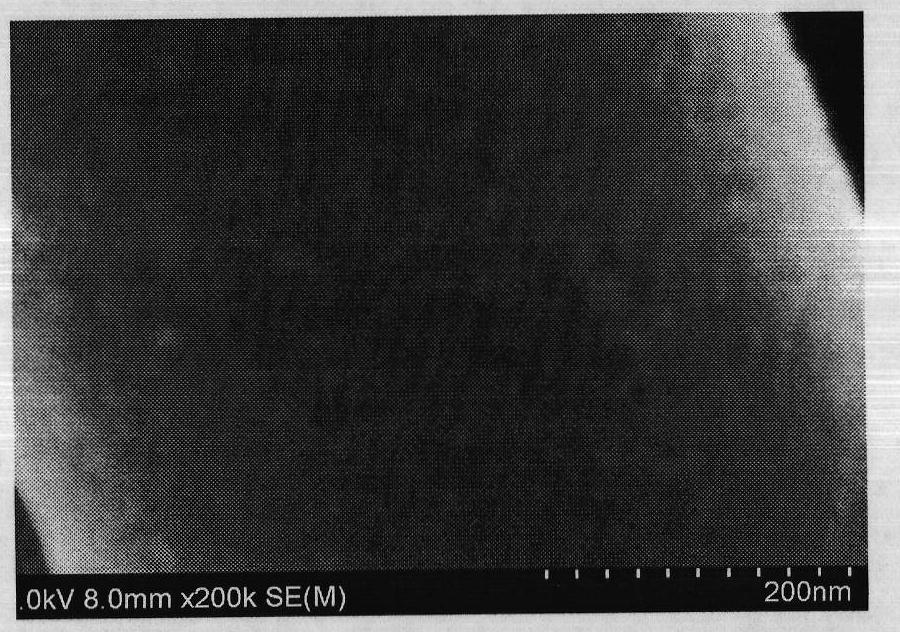

[0008] A flexible α-Al 2 o 3 Ceramic fiber, characterized in that the basic structural unit of the fiber is α-Al of 10-40nm 2 o 3 Nanoparticles and 20-30nm thick α-Al 2 o 3 Nano sheet, the fiber diameter is 350-800nm.

[0009] The molar ratio of aluminum to silicon in the fiber is 1:0.004˜1:0.031.

[0010] A flexible α-Al 2 o 3 The preparation method of ceramic fiber comprises steps as follows:

[0011] (1) Add aluminum chloride to the dissolved amount of deionized water, stir until completely dissolved, add tetraethyl orthosilicate (TEOS), stir for 10-15 minutes, then add aluminum isopropoxide and absolute ethanol, and finally Add glacial acetic acid and hydrochloric acid to adjust the pH value to 1.8-2.5, stir until the solution is clear, add polyvinylpyrrolidone (PVP), and stir until the PVP is completely dissolved to obtain a sol spinning solution. in,

[0012] The molar ratio of aluminum chloride to aluminum isopropoxide is 1:3 to 1:5, the molar ratio of the tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com